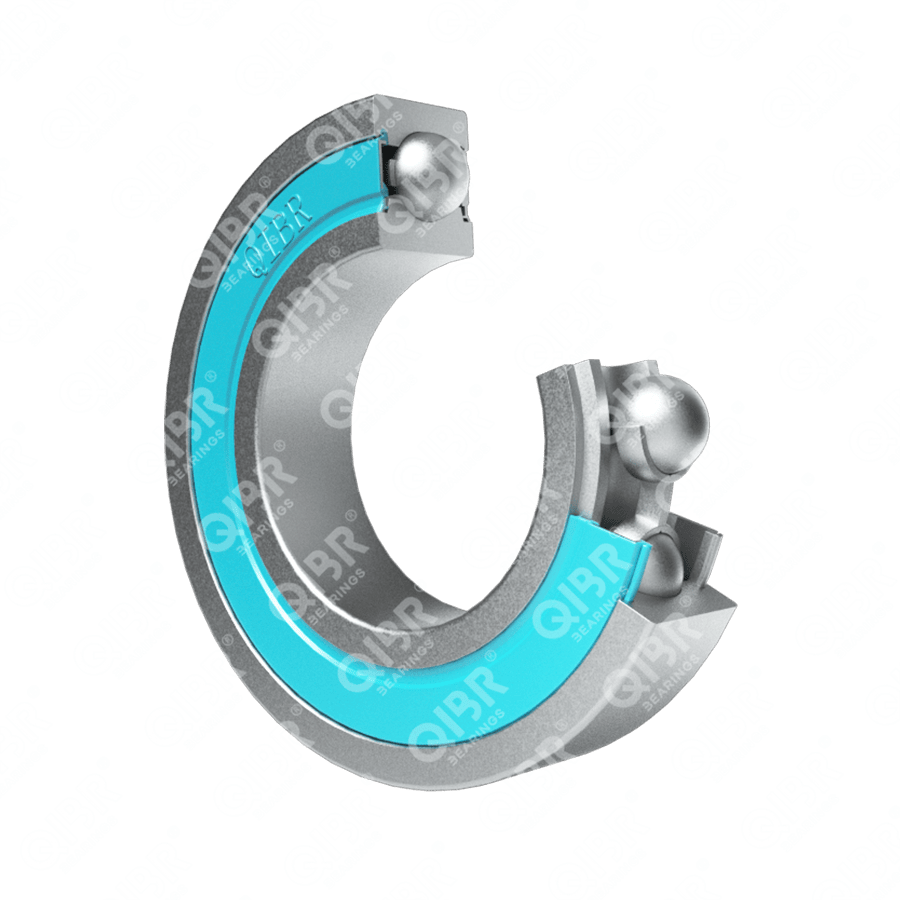

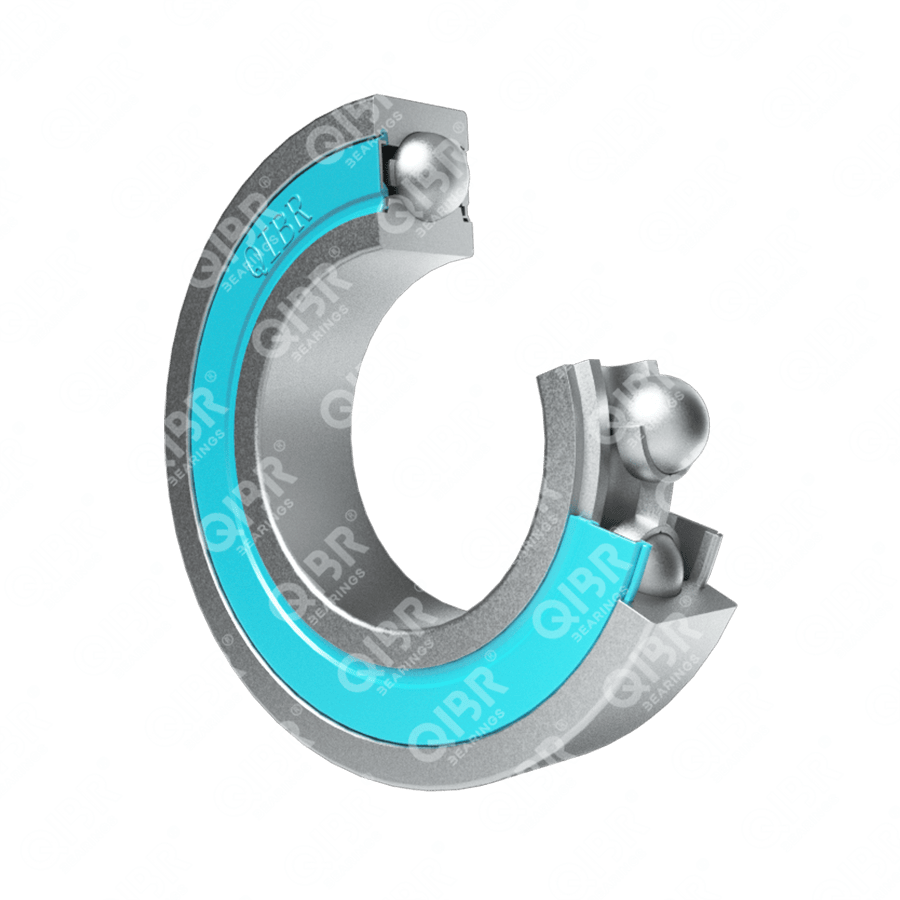

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

304 316 420 440

Inner ring diameter

1mm-50mm

Outer ring diameter

3mm-90mm

Weight

0.03g-453g

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

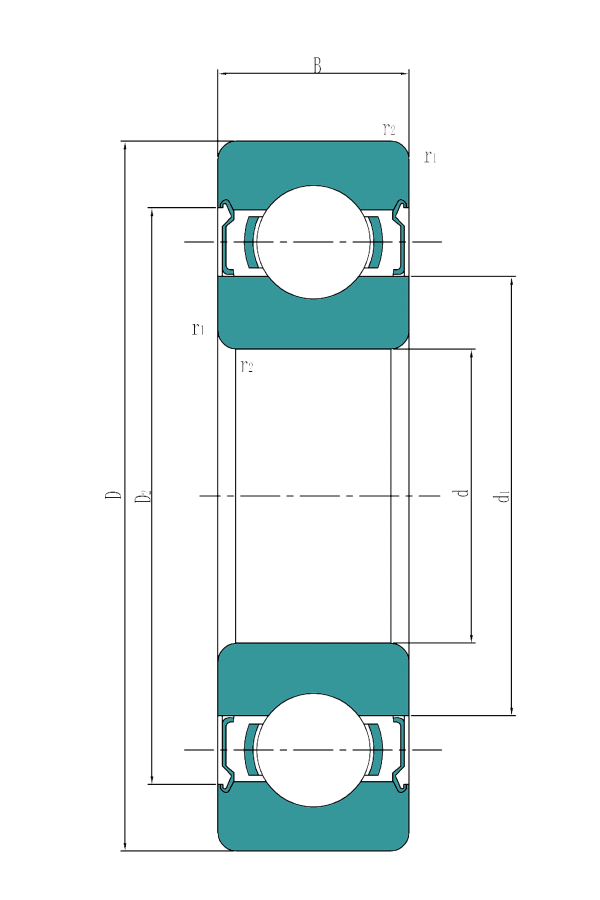

| NO. | Product | Product Number | Outer diameter (D) | Inner diameter (d) | Width (B) | Mass | Basic dynamic load rating | Basic static load rating |

|---|---|---|---|---|---|---|---|---|

| 101 |

|

W 61901 2Z | 24 mm | 12 mm | 6 mm | 11 g | 2.51 KN | 1.46 KN |

| 102 |

|

W 61901 | 24 mm | 12 mm | 6 mm | 9.8 g | 2.51 KN | 1.46 KN |

| 103 |

|

W 6001 2RS1 | 28 mm | 12 mm | 8 mm | 20 g | 4.42 KN | 2.36 KN |

| 104 |

|

W 6001 2Z | 28 mm | 12 mm | 8 mm | 20 g | 4.42 KN | 2.36 KN |

| 105 |

|

W 6001 | 28 mm | 12 mm | 8 mm | 18 g | 4.42 KN | 2.36 KN |

| 106 |

|

W 6201 2RS1 | 32 mm | 12 mm | 10 mm | 36 g | 5.72 KN | 3 KN |

| 107 |

|

W 6201 2Z | 32 mm | 12 mm | 10 mm | 36 g | 5.72 KN | 3 KN |

| 108 |

|

W 6201 | 32 mm | 10 mm | 5.72 mm | 33.5 g | 3 KN | 0.127 KN |

| 109 |

|

W 6301 2RS1 | 37 mm | 12 mm | 12 mm | 58.5 g | 8.32 KN | 4.15 KN |

| 110 |

|

W 6301 2Z | 37 mm | 12 mm | 12 mm | 59.5 g | 8.32 KN | 4.15 KN |

| 111 |

|

W 6301 | 37 mm | 12 mm | 12 mm | 55.5 g | 8.32 KN | 4.15 KN |

| 112 |

|

W 61802 2RS1 | 24 mm | 15 mm | 5 mm | 7.1 g | 1.65 KN | 1.08 KN |

| 113 |

|

W 61802 2Z | 24 mm | 15 mm | 5 mm | 6.7 g | 1.65 KN | 1.08 KN |

| 114 |

|

W 61902 2RS1 | 28 mm | 15 mm | 7 mm | 16 g | 3.71 KN | 2.24 KN |

| 115 |

|

W 61902 2Z | 28 mm | 15 mm | 7 mm | 16 g | 3.71 kN | 2.24 KN |

| 116 |

|

W 61902 | 28 mm | 15 mm | 7 mm | 14.5 g | 3.71 KN | 2.24 KN |

| 117 |

|

W 6002 2RS1 | 32 mm | 15 mm | 9 mm | 28.5 g | 4.48 KN | 2.8 KN |

| 118 |

|

W 6002 2Z | 32 mm | 15 mm | 9 mm | 29 g | 4.88 KN | 2.8 KN |

| 119 |

|

W 6002 | 32 mm | 15 mm | 9 mm | 26.5 g | 4.88 KN | 2.8 KN |

| 120 |

|

W 6202 2RS1 | 35 mm | 15 mm | 11 mm | 44 g | 6.37 KN | 3.6 KN |

| 121 |

|

W 6202 2Z | 35 mm | 15 mm | 11 mm | 44 g | 6.37 KN | 3.6 KN |

| 122 |

|

W 6202 | 35 mm | 15 mm | 11 mm | 41.5 g | 6.37 KN | 3.6 KN |

| 123 |

|

W 6302 2RS1 | 42 mm | 15 mm | 13 mm | 81 g | 9.95 KN | 5.4 KN |

| 124 |

|

W 6302 2Z | 42 mm | 15 mm | 13 mm | 82 g | 9.95 KN | 5.4 KN |

| 125 |

|

W 6302 | 42 mm | 15 mm | 13 mm | 77 g | 9.95 KN | 5.4 KN |

| 126 |

|

W 61803 2RS1 | 26 mm | 17 mm | 5 mm | 8 g | 1.78 KN | 1.27 KN |

| 127 |

|

W 61803 2Z | 26 mm | 17 mm | 5 mm | 7.6 g | 1.78 KN | 1.27 KN |

| 128 |

|

W 61903 2RS1 | 30 mm | 17 mm | 7mm | 16.5 g | 3.97 KN | 2.55 KN |

| 129 |

|

W 61903 2Z | 30 mm | 17 mm | 7 mm | 17 g | 3.97 KN | 12.55 KN |

| 130 |

|

W 61903 | 30 mm | 17 mm | 7 mm | 15.5 g | 3.97 KN | 2.55 KN |

| 131 |

|

W 6003 2RS1 | 35 mm | 17 mm | 10 mm | 38 g | 4.94 KN | 3.15 KN |

| 132 |

|

W 6003 2Z | 35 mm | 17 mm | 10 mm | 38.5 g | 4.94 KN | 3.15 KN |

| 133 |

|

W 6003 | 35 mm | 17 mm | 10 mm | 36 g | 4.94 KN | 3.15 KN |

| 134 |

|

W 6203 2RS1 | 40 mm | 17 mm | 12 mm | 64.5 g | 8.06 KN | 4.75 KN |

| 135 |

|

W 6203 2Z | 40 mm | 17 mm | 12 mm | 65.5 g | 8.06 KN | 4.75 KN |

| 136 |

|

W 6203 | 40 mm | 17 mm | 12 mm | 61.5 g | 8.06 KN | 4.75 KN |

| 137 |

|

W 6303 2RS1 | 47 mm | 17 mm | 14 mm | 112 g | 11.7 KN | 6.55 KN |

| 138 |

|

W 6303 2Z | 47 mm | 17 mm | 14 mm | 113 g | 11.7 kN | 6.55 kN |

| 139 |

|

W 6303 | 47 mm | 17 mm | 14 mm | 107 g | 11.7 KN | 6.55 KN |

| 140 |

|

W 61804 2RS1 | 32 mm | 20 mm | 7 mm | 17 g | 3.12 KN | 2.08 KN |

| 141 |

|

W 61804 2Z | 32 mm | 20 mm | 7 mm | 17 g | 3.12 KN | 2.08 KN |

| 142 |

|

W 61904 2RS1 | 37 mm | 20 mm | 9 mm | 35.5 g | 5.53 KN | 3.65 KN |

| 143 |

|

W 61904 | 37 mm | 20 mm | 9 mm | 32.5 g | 5.53 KN | 3.65 KN |

| 144 |

|

W 6004 2RS1 | 42 mm | 20 mm | 12 mm | 64.5 g | 8.06 KN | 5 KN |

| 145 |

|

W 6004 2Z | 42 mm | 20 mm | 12 mm | 64.5 g | 8.06 KN | 5 KN |

| 146 |

|

W 6004 | 42 mm | 20 mm | 12 mm | 60.5 g | 8.06 KN | 5 KN |

| 147 |

|

W 6204 2RS1 | 42 mm | 20 mm | 14 mm | 105 g | 10.8 KN | 6.55 KN |

| 148 |

|

W 6204 2Z | 47 mm | 20 mm | 14 mm | 144 g | 10.8 KN | 6.55 KN |

| 149 |

|

W 6204 | 47 mm | 20 mm | 14 mm | 100 g | 10.8 KN | 6.55 KN |

| 150 |

|

W 6304 2RS1 | 52 mm | 20 mm | 15 mm | 143 g | 13.8 KN | 7.8 KN |

| 151 |

|

W 6304 2Z | 52 mm | 20 mm | 15 mm | 144 g | 13.8 KN | 7.8 KN |

| 152 |

|

W 6304 | 52 mm | 20 mm | 15 mm | 136 g | 13.8 KN | 7.8 KN |

| 153 |

|

W 61805 2RS1 | 37 mm | 25 mm | 7 mm | 21 g | 3.38 KN | 2.5 KN |

| 154 |

|

W 61805 2Z | 37 mm | 25 mm | 7 mm | 21 g | 3.38 KN | 2.5 KN |

| 155 |

|

W 61905 2RS1 | 42 mm | 25 mm | 9 mm | 39.5 g | 6.05 KN | 4.5 KN |

| 156 |

|

W 6005 2RS1 | 47 mm | 25 mm | 12 mm | 76.5 g | 8.71 KN | 6.85 KN |

| 157 |

|

W 6005 2Z | 47 mm | 25 mm | 12 mm | 77.5 g | 8.71 KN | 5.85 KN |

| 158 |

|

W 6005 | 47 mm | 25 mm | 12 mm | 71.5 g | 8.71 KN | 5.85 KN |

| 159 |

|

W 6205 2RS1 | 52 mm | 25 mm | 15 mm | 128 g | 11.7 KN | 7.65 KN |

| 160 |

|

W 6205 2Z | 52 mm | 25 mm | 15 mm | 130 g | 11.7 KN | 7.65 KN |

| 161 |

|

W 6205 | 52 mm | 25 mm | 15 mm | 122 g | 11.7 KN | 7.65 KN |

| 162 |

|

W 6305 2RS1 | 62 mm | 25 mm | 17 mm | 234 g | 17.8 KN | 11.2 KN |

| 163 |

|

W 6305 2Z | 62 mm | 25 mm | 17 mm | 235 g | 17.8 KN | 11.2 KN |

| 164 |

|

W 6305 | 62 mm | 25 mm | 17 mm | 224 g | 17.8 KN | 11.2 KN |

| 165 |

|

W 61806 2RS1 | 42 mm | 30 mm | 7 mm | 24 g | 3.58 KN | 2.9 KN |

| 166 |

|

W 61906 2RS1 | 47 mm | 30 mm | 9 mm | 47 g | 6.24 KN | 5 KN |

| 167 |

|

W 61906 | 47 mm | 30 mm | 9 mm | 43.5 g | 6.24 KN | 5 KN |

| 168 |

|

W 6006 2RS1 | 55 mm | 30 mm | 13 mm | 112 g | 11.4 KN | 8.15 KN |

| 169 |

|

W 6006 2Z | 55 mm | 30 mm | 13 mm | 113 g | 11.4 KN | 8.15 KN |

| 170 |

|

W 6006 | 55 mm | 30 mm | 13 mm | 105 g | 11.4 KN | 8.15 KN |

| 171 |

|

W 6206 2RS1 | 62 mm | 30 mm | 16 mm | 196 g | 16.5 KN | 11.2 KN |

| 172 |

|

W 6206 2Z | 62 mm | 30 mm | 16 mm | 196 g | 16.5 KN | 11.2 KN |

| 173 |

|

W 6206 | 62 mm | 30 mm | 16 mm | 186 g | 16.5 KN | 11.2 KN |

| 174 |

|

W 6306 2RS1 | 72 mm | 30 mm | 19 mm | 346 g | 22.9 KN | 15 KN |

| 175 |

|

W 6306 2Z | 72 mm | 30 mm | 19 mm | 345 g | 22.9 KN | 15 KN |

| 176 |

|

W 6306 | 72 mm | 30 mm | 19 mm | 331 g | 22.9 KN | 15 KN |

| 177 |

|

W 61807 2RS1 | 47 mm | 35 mm | 7 mm | 29.5 g | 3.71 KN | 3.35 KN |

| 178 |

|

W 61907 2RS1 | 55 mm | 35 mm | 10 mm | 73.5 g | 9.36 KN | 7.65 KN |

| 179 |

|

W 6007 2RS1 | 62 mm | 35 mm | 14 mm | 147 g | 13.8 KN | 10.2 KN |

| 180 |

|

W 6007 2Z | 62 mm | 35 mm | 14 mm | 148 g | 13.8 KN | 10.2 KN |

| 181 |

|

W 6007 | 62 mm | 35 mm | 14 mm | 138 g | 13.8 KN | 10.2 KN |

| 182 |

|

W 6207 2RS1 | 72 mm | 35 mm | 17 mm | 276 g | 22.1 KN | 15.3 KN |

| 183 |

|

W 6207 2Z | 72 mm | 35 mm | 17 mm | 277 g | 22.1 KN | 15.3 KN |

| 184 |

|

W 6207 | 72 mm | 35 mm | 17 mm | 262 g | 22.1 KN | 15.3 KN |

| 185 |

|

W 6307 2RS1 | 80 mm | 35 mm | 21 mm | 441 g | 28.6 KN | 19 KN |

| 186 |

|

W 61908 2RS1 | 62 mm | 40 mm | 12 mm | 107 g | 11.9 KN | 9.8 KN |

| 187 |

|

W 6008 2RS1 | 68 mm | 40 mm | 15 mm | 182 g | 14.6 KN | 11.4 KN |

| 188 |

|

W 6008 2Z | 68 mm | 40 mm | 15 mm | 183 g | 14.6 KN | 11.4 KN |

| 189 |

|

W 6008 | 68 mm | 40 mm | 15 mm | 172 g | 14.6 KN | 11.4 KN |

| 190 |

|

W 6208 2RS1 | 80 mm | 40 mm | 18 mm | 359 g | 25.1 KN | 17.6 KN |

| 191 |

|

W 6208 2Z | 80 mm | 40 mm | 18 mm | 359 g | 25.1 KN | 17.6 KN |

| 192 |

|

W 6208 | 80 mm | 40 mm | 18 mm | 342 g | 25.1 KN | 17.6 KN |

| 193 |

|

W 6009 2RS1 | 75 mm | 45 mm | 16 mm | 236 g | 18.2 KN | 15 KN |

| 194 |

|

W 6009 2Z | 75 mm | 45 mm | 16 mm | 237 g | 18.2 KN | 15 KN |

| 195 |

|

W 6209 2RS1 | 85 mm | 45 mm | 19 mm | 395 g | 28.1 KN | 20.4 KN |

| 196 |

|

W 6209 2Z | 85 mm | 45 mm | 19 mm | 394 g | 28.1 KN | 20.4 KN |

| 197 |

|

W 6010 2RS1 | 80 mm | 50 mm | 16 mm | 256 g | 19 KN | 16.6 KN |

| 198 |

|

W 6010 2Z | 80 mm | 50 mm | 16 mm | 256 g | 19 KN | 16.6 KN |

| 199 |

|

W 6210 2RS1 | 90 mm | 50 mm | 20 mm | 449 g | 30.2 KN | 23.2 KN |

| 200 |

|

W 6210 2Z | 90 mm | 50 mm | 20 mm | 453 g | 30.2 KN | 23.2 KN |

Features and advantages of QIBR stainless steel deep groove ball bearing

QIBR stainless steel deep groove ball bearings solve multiple key problems across various fields, mainly in the following aspects:

1. Strong corrosion resistance

Made from stainless steel materials, they offer excellent corrosion resistance, suitable for humid and corrosive environments.

2. High and low temperature adaptability

Maintains stable performance under both high and low temperatures, making them suitable for extreme temperature environments.

3. Long service life

The corrosion and wear resistance ensures a long service life even in harsh environments.

4. Low maintenance costs

Corrosion resistance and self-lubricating properties reduce the frequency and cost of maintenance.

5. Wide range of applications

Suitable for industries such as food, chemicals, and medical, with outstanding performance in humid and corrosive environments.

Performance enhancements and solutions for QIBR stainless steel deep groove ball bearing

1. Lubricant optimization

Choose suitable lubricating oil or grease, and adjust the formulation to reduce friction and enhance wear resistance. Using synthetic lubricants or nano-lubricating oils can significantly improve bearing efficiency and lifespan.

2. Raceway optimization

Optimize the geometry of the inner and outer raceways, such as increasing raceway precision and improving surface smoothness, to reduce friction, minimize energy loss, and improve bearing operational efficiency.

3. Improve rolling element quality

Enhance the surface finish and hardness of rolling elements to reduce friction and wear. Using high-precision rolling elements (e.g., ceramic bearings) can significantly improve bearing performance.

4. Efficient seals

Use contact or non-contact seals to prevent contaminants from entering and reduce lubricant leakage.

Main application fields of QIBR stainless steel deep groove ball bearing

1. Food and beverage industry

Application: Used in food processing equipment, filling lines, and packaging machinery.

Reason: Corrosion-resistant, easy to clean, meets food safety standards.

2. Chemical industry

Application: Used in pumps, mixers, compressors, and other equipment.

Reason: Resistant to chemical corrosion, suitable for harsh environments.

3. Medical industry

Application: Used in surgical instruments, medical devices, and diagnostic equipment.

Reason: High precision, corrosion-resistant, meets hygiene standards.

4. Marine and shipbuilding industry

Application: Used in ship propulsion systems, deck machinery, and offshore platform equipment.

Reason: Resistant to seawater corrosion, suitable for high humidity environments.

5. Aerospace industry

Application: Used in aircraft engines, landing gear, and navigation systems.

Reason: Resistant to extreme temperatures, suitable for extreme environments.