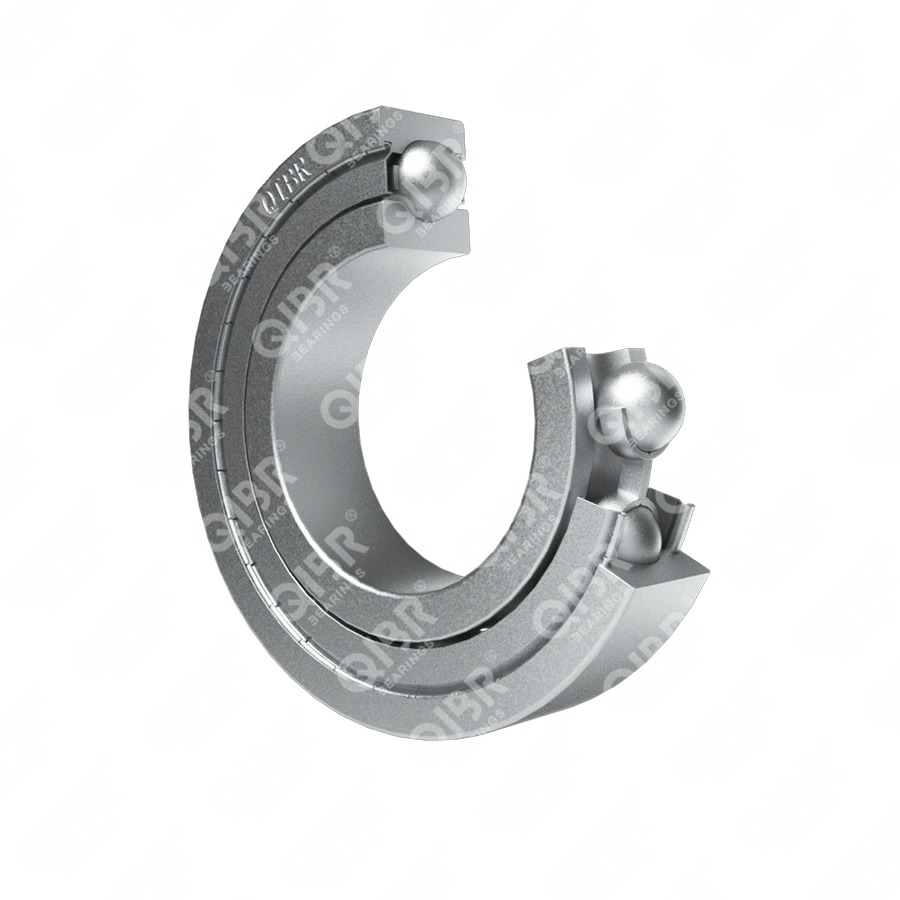

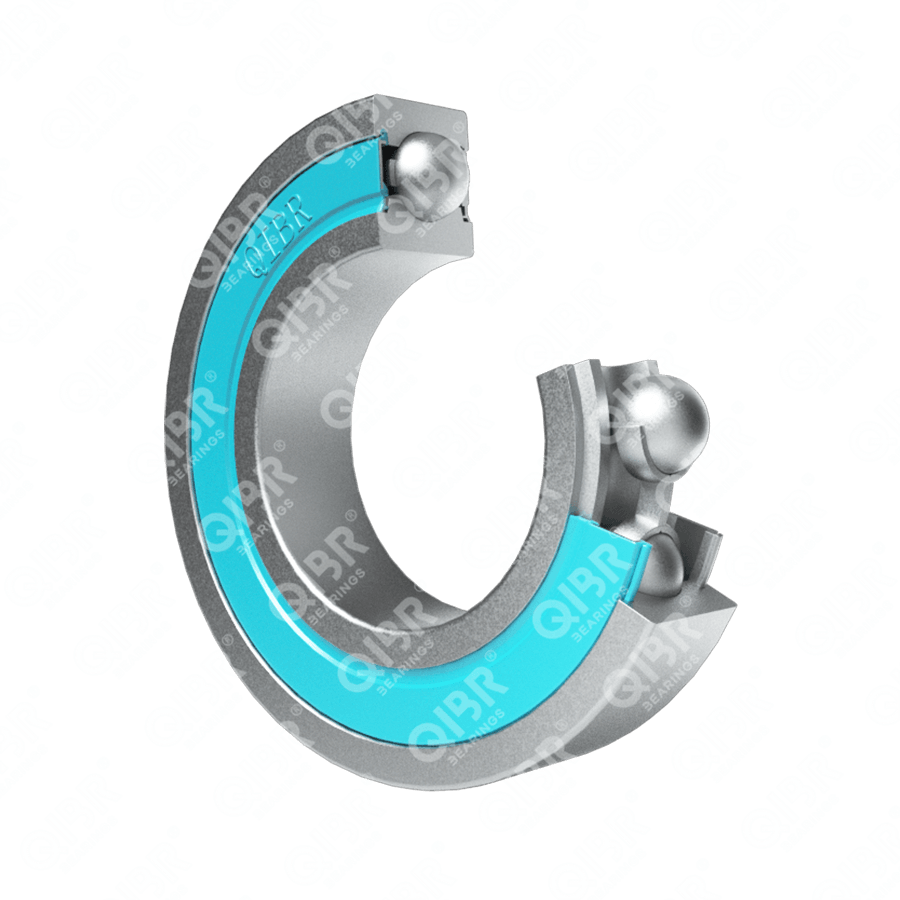

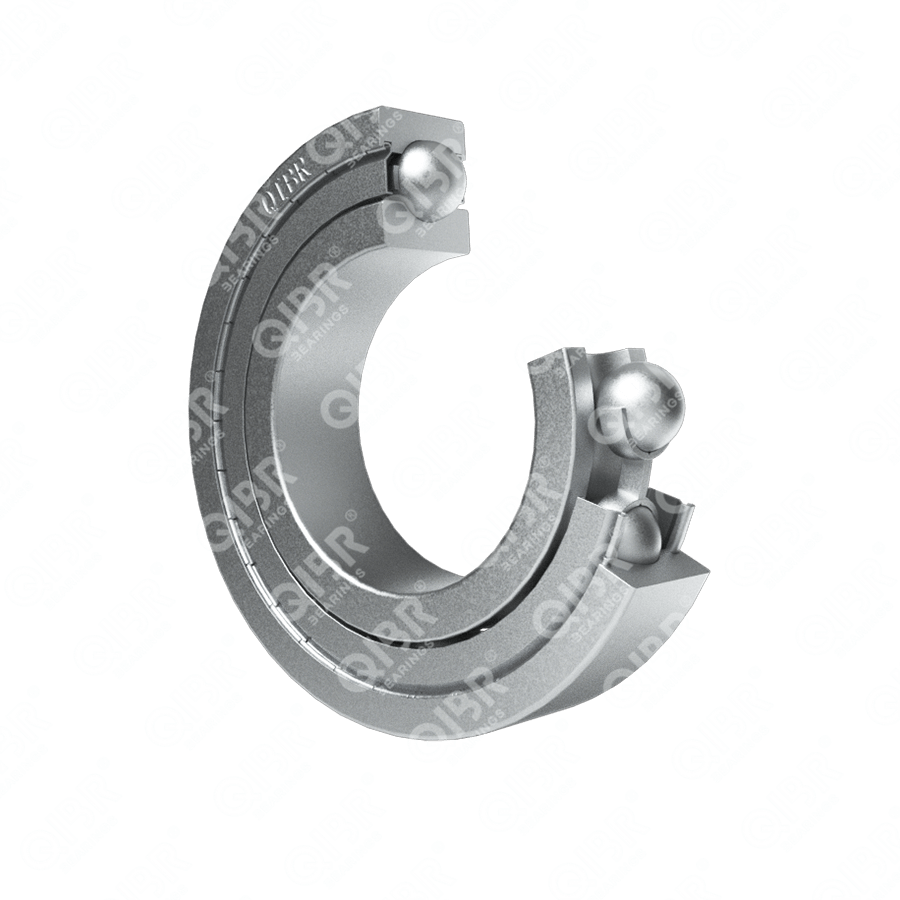

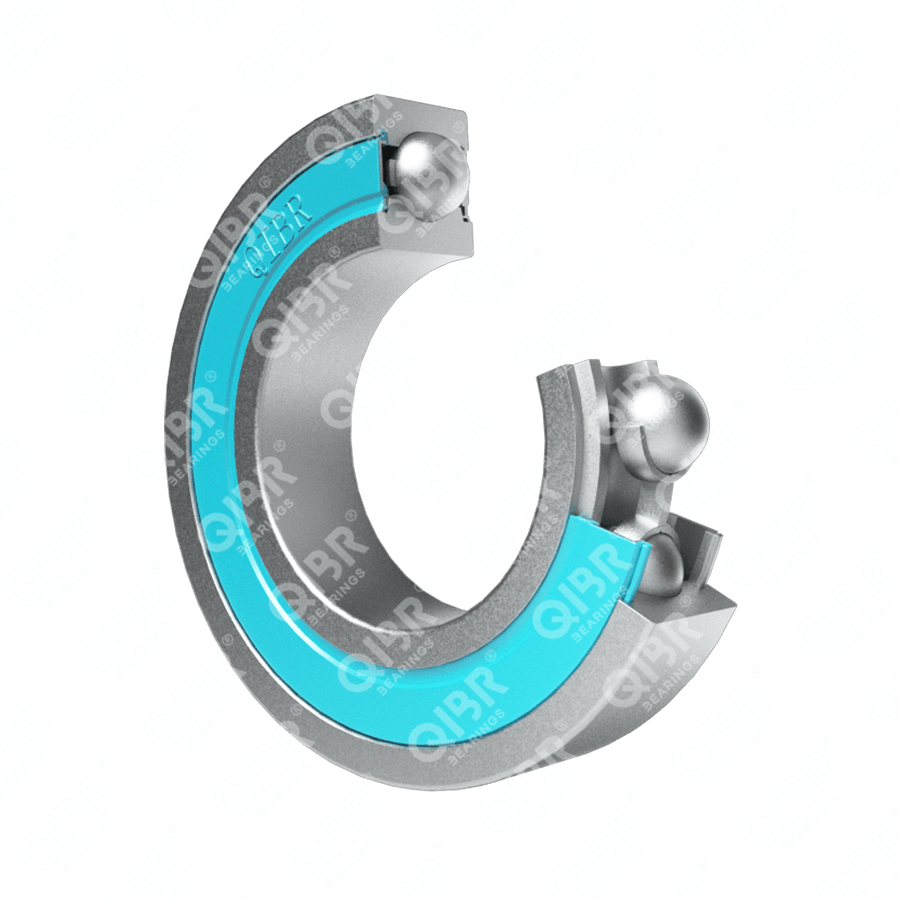

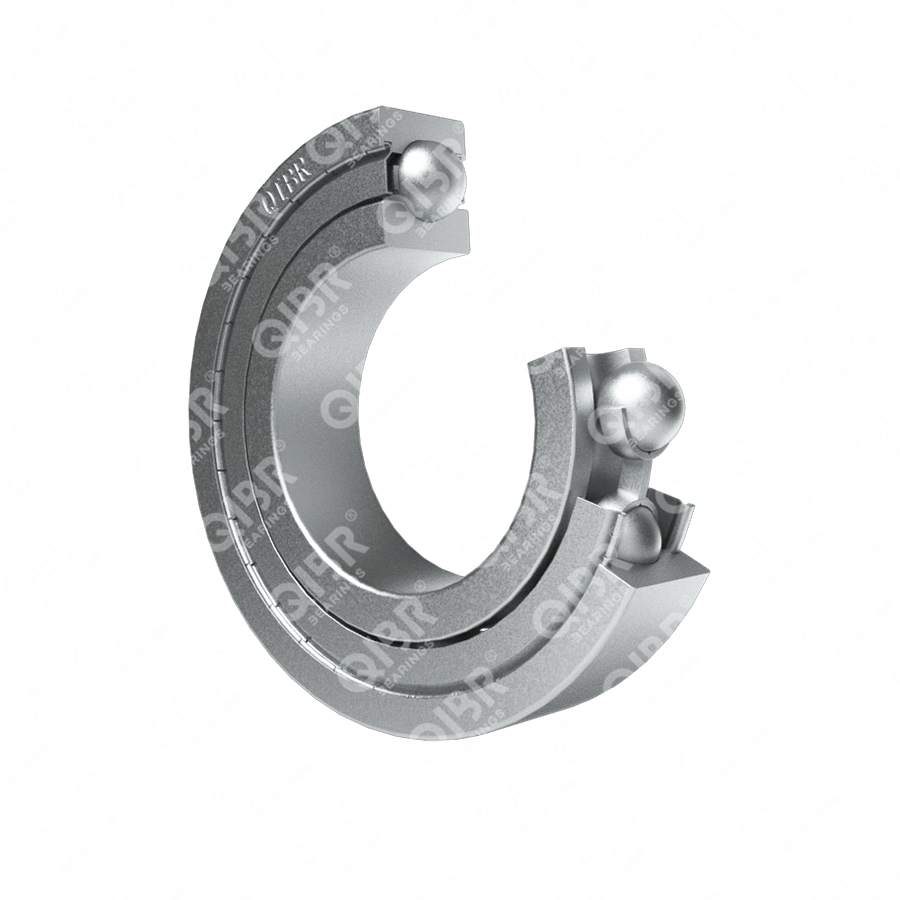

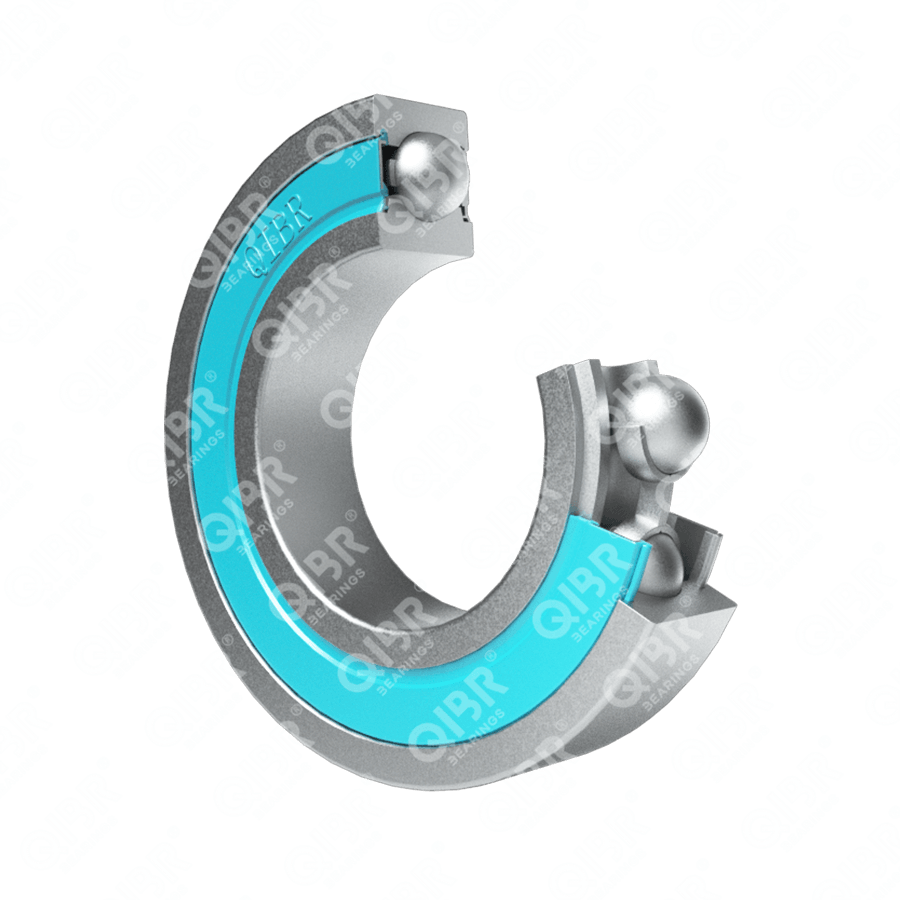

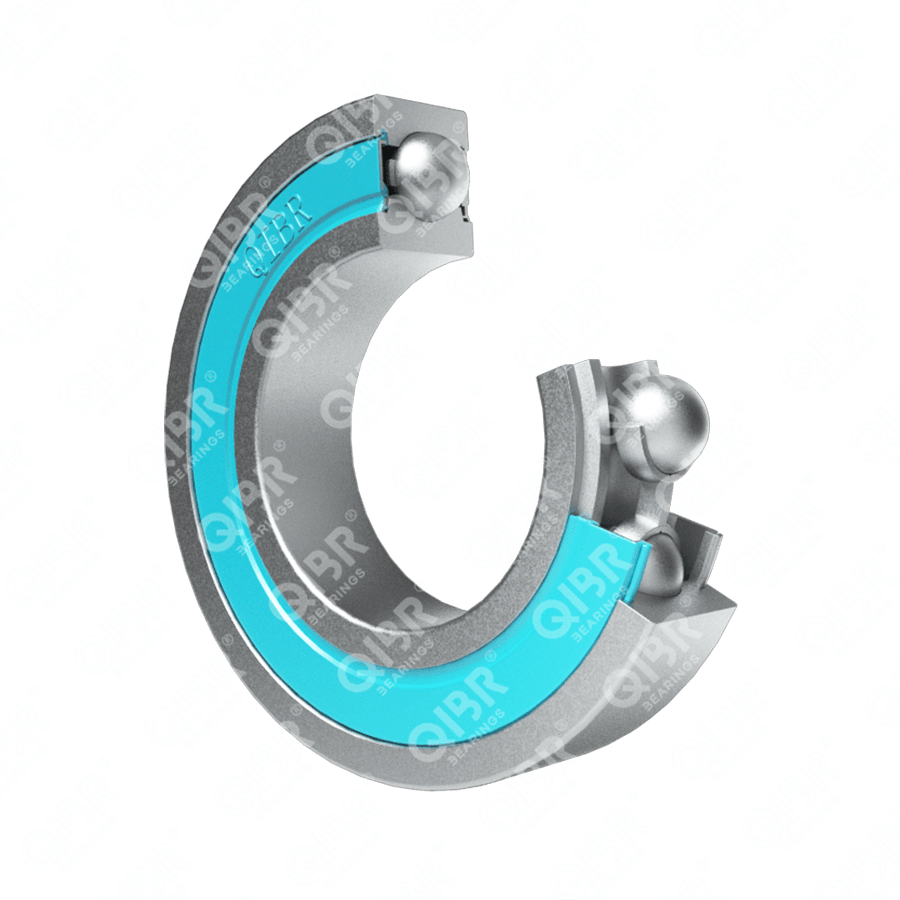

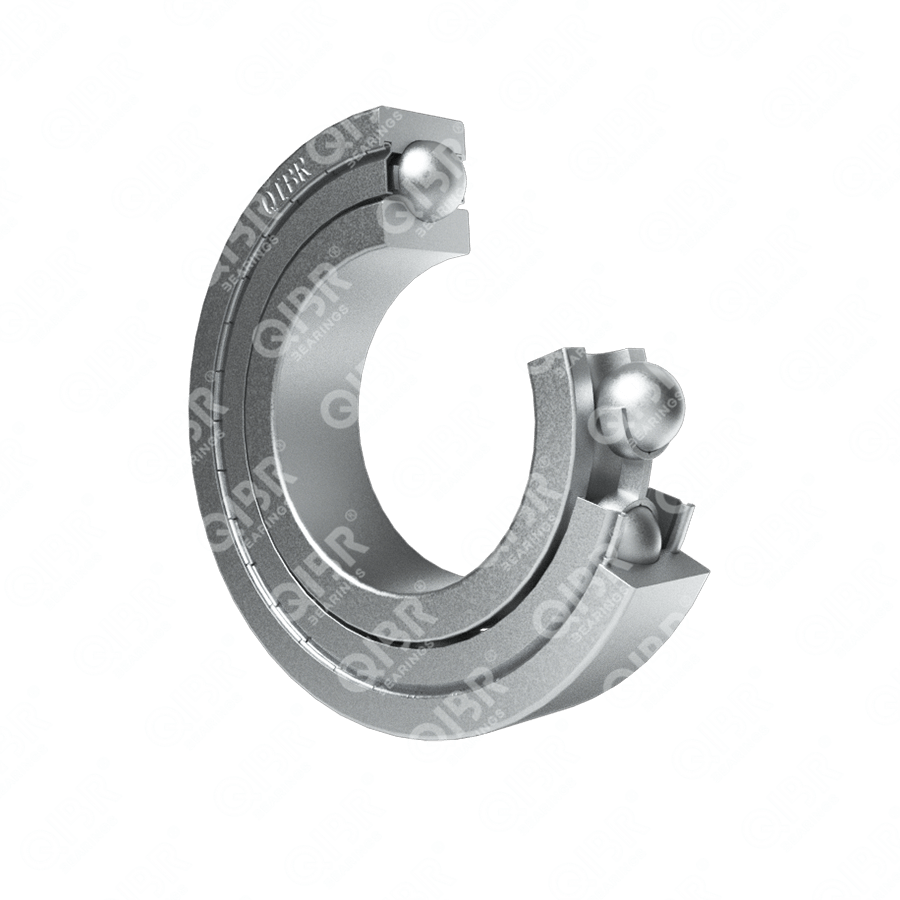

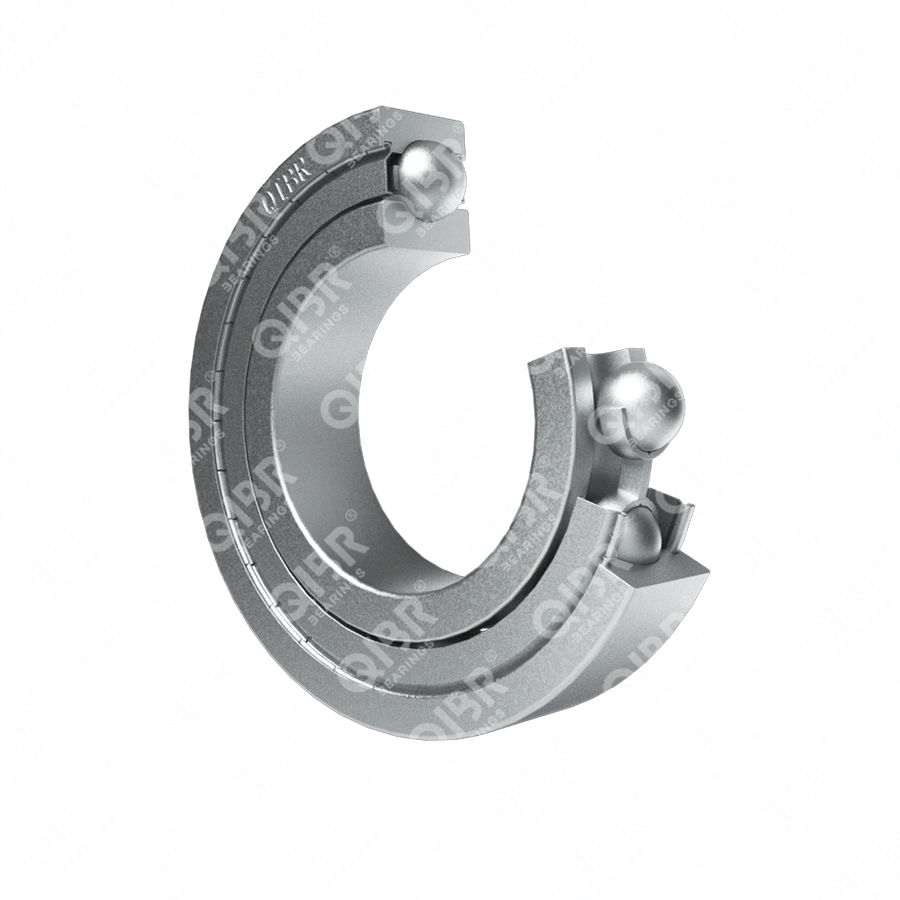

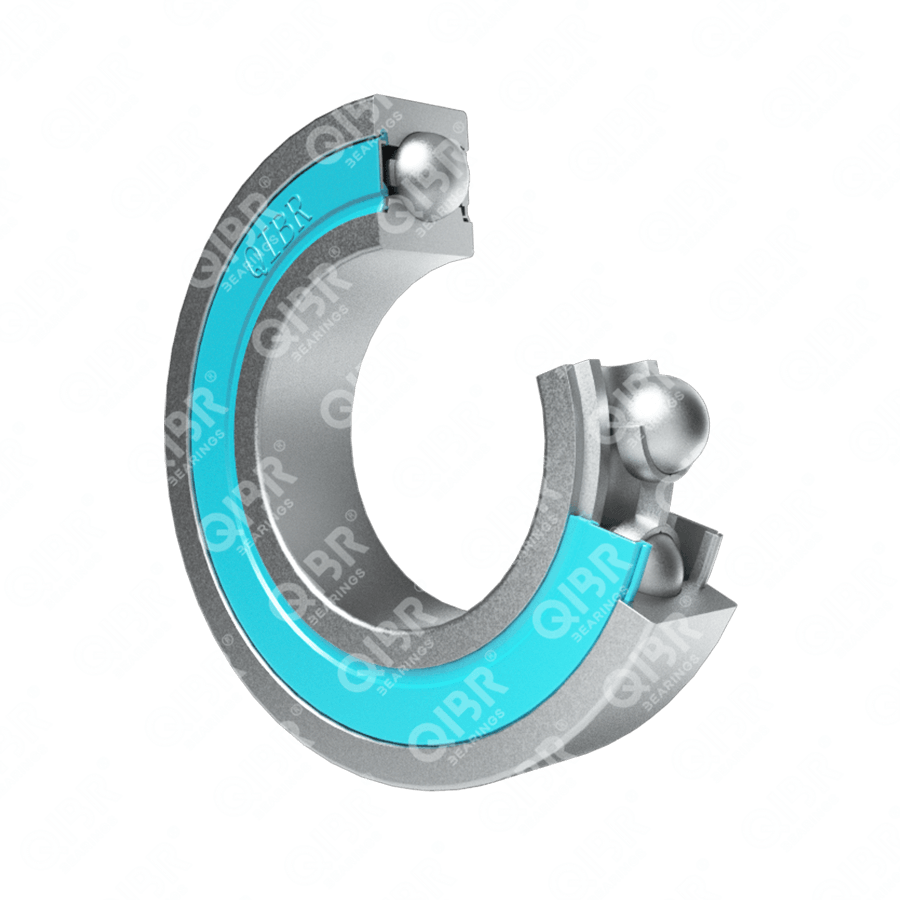

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

GCr15、5200、100Cr6、SUJ2

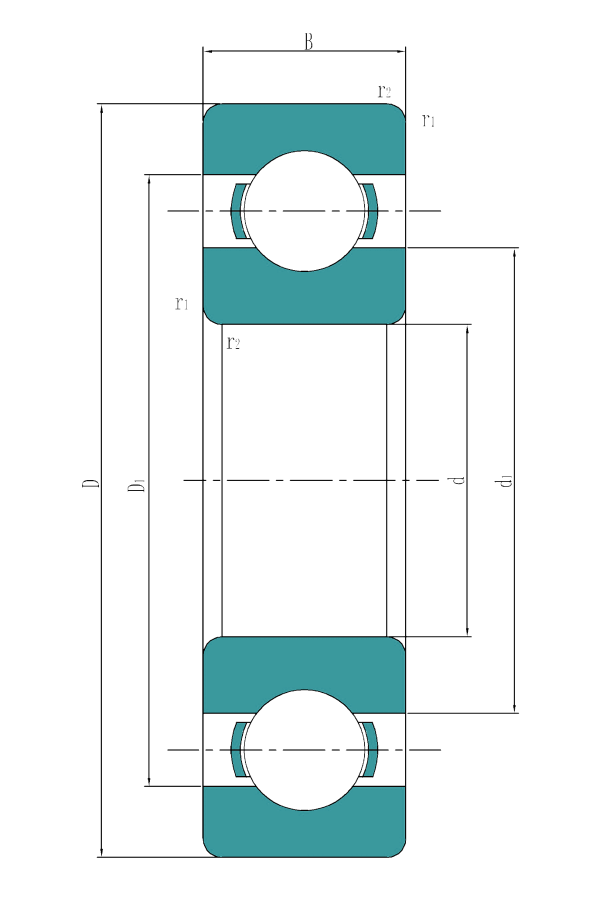

Inner ring diameter

3mm-1500mm

Outer ring diameter

10mm-1920mm

Weight

0.0007kg-500kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

| NO. | Product | Product Number | Outer diameter (D) | Inner diameter (d) | Width (B) | Mass | Basic static load rating | Basic dynamic load rating |

|---|---|---|---|---|---|---|---|---|

| 101 |

|

623 2Z | 10 mm | 3 mm | 4 mm | 0.001 kg | 220 KN | 640 KN |

| 102 |

|

623 RS1 | 10 mm | 3 mm | 4 mm | 0.0015 kg | 0.18 KN | 0.54 KN |

| 103 |

|

623 2Z | 10 mm | 3 mm | 4 mm | 0.0015 kg | 0.18 KN | 0.54 KN |

| 104 |

|

624 | 13 mm | 4 mm | 5 mm | 0.003 kg | 490 KN | 1290 KN |

| 105 |

|

623 Z | 10 mm | 3 mm | 4 mm | 0.0015 kg | 0.18 KN | 0.54 KN |

| 106 |

|

624 2RSR | 13 mm | 4 mm | 5 mm | 0.003 kg | 490 KN | 1290 KN |

| 107 |

|

618/4 | 9 mm | 4 mm | 2.5 mm | 0.0007 kg | 0.116 KN | 0.423 KN |

| 108 |

|

624 2Z | 13 mm | 4 mm | 5 mm | 0.003 kg | 490 KN | 1290 KN |

| 109 |

|

628/4 2Z | 9 mm | 4 mm | 3.5 mm | 0.001 kg | 0.18 KN | 0.54 KN |

| 110 |

|

634 | 16 mm | 4 mm | 5 mm | 0.004 kg | 670 KN | 1730 KN |

| 111 |

|

634 2RSR | 16 mm | 4 mm | 5 mm | 0.006 kg | 670 KN | 1730 KN |

| 112 |

|

638/4 2Z | 9 mm | 4 mm | 3.5 mm | 0.0013 kg | 0.18 KN | 0.54 KN |

| 113 |

|

619/4 2Z | 11 mm | 4 mm | 4 mm | 0.0017 kg | 0.18 KN | 0.624 KN |

| 114 |

|

634 2Z | 16 mm | 4 mm | 5 mm | 0.006 kg | 670 KN | 1730 KN |

| 115 |

|

619/4 | 11 mm | 4 mm | 4 mm | 0.0017 kg | 0.18 KN | 0.624 KN |

| 116 |

|

625 | 16 mm | 5 mm | 5 mm | 0.005 kg | 440 KN | 1320 KN |

| 117 |

|

604 | 12 mm | 4 mm | 4 mm | 0.0021 kg | 0.28 KN | 0.806 KN |

| 118 |

|

625 2RSR | 16 mm | 5 mm | 5 mm | 0.005 kg | 440 KN | 1320 KN |

| 119 |

|

604 2Z | 12 mm | 4 mm | 4 mm | 0.0021 kg | 0.28 KN | 0.806 KN |

| 120 |

|

625 2Z | 16 mm | 5 mm | 5 mm | 0.005 kg | 440 KN | 1320 KN |

| 121 |

|

604 Z | 12 mm | 4 mm | 4mm | 0.0021 kg | 0.28 KN | 0.806 KN |

| 122 |

|

635 | 19 mm | 5 mm | 6 mm | 0.008 kg | 1100 KN | 2600 KN |

| 123 |

|

624 | 13 mm | 4 mm | 5 mm | 0.0031 kg | 0.29 KN | 0.936 KN |

| 124 |

|

635 2RSR | 19 mm | 5 mm | 6 mm | 0.008 kg | 1100 KN | 2600 KN |

| 125 |

|

624 2Z | 13 mm | 4 mm | 5 mm | 0.0031 kg | 0.29 KN | 0.936 KN |

| 126 |

|

635 2Z | 19 mm | 5 mm | 6 mm | 0.008 kg | 1100 KN | 2600 KN |

| 127 |

|

624 Z | 13 mm | 4 mm | 5 mm | 0.0031 kg | 0.29 KN | 0.936 KN |

| 128 |

|

626 | 19 mm | 6 mm | 6 mm | 0.008 kg | 1100 KN | 2600 KN |

| 129 |

|

626 2RSR | 19 mm | 6 mm | 6 mm | 0.008 kg | 1100 KN | 2600 KN |

| 130 |

|

634 | 16 mm | 4 mm | 5 mm | 0.0054 kg | 0.38 KN | 1.11 KN |

| 131 |

|

626 2Z | 19 mm | 6 mm | 6 mm | 0.008 kg | 1100 KN | 2600 KN |

| 132 |

|

634 2RS1 | 16 mm | 4 mm | 5 mm | 0.0054 kg | 0.38 KN | 1.11 KN |

| 133 |

|

607 | 19 mm | 7 mm | 6 mm | 0.007 kg | 1100 KN | 2600 KN |

| 134 |

|

634 RS1 | 16 mm | 4 mm | 5mm | 0.0054 kg | 0.38 KN | 1.11 KN |

| 135 |

|

607 2RSR | 19 mm | 7 mm | 6 mm | 0.007 kg | 1100 KN | 2600 KN |

| 136 |

|

634 2RZ | 16 mm | 4 mm | 5 mm | 0.0054 kg | 0.38 KN | 1.11 KN |

| 137 |

|

607 2Z | 19 mm | 7 mm | 6 mm | 0.008 kg | 1100 KN | 2600 KN |

| 138 |

|

634 RZ | 16 mm | 4 mm | 5 mm | 0.0054 kg | 0.38 KN | 1.11 KN |

| 139 |

|

627 | 22 mm | 7 mm | 7 mm | 0.011 kg | 1370 KN | 3250 KN |

| 140 |

|

634 2Z | 16 mm | 4 mm | 5 mm | 0.0054 kg | 0.38 KN | 1.11 KN |

| 141 |

|

627 2RSR | 22 mm | 7 mm | 7 mm | 0.011 kg | 1370 KN | 3250 KN |

| 142 |

|

634 Z | 16 mm | 4 mm | 5 mm | 0.0054 kg | 0.38 KN | 1.11 KN |

| 143 |

|

618/5 | 11 mm | 5 mm | 3 mm | 0.0012 kg | 0.143 KN | 0.468 KN |

| 144 |

|

627 2Z | 22 mm | 7 mm | 7 mm | 0.012 kg | 1370 KN | 3250 KN |

| 145 |

|

608 | 22 mm | 8 mm | 7 mm | 0.01 kg | 1370 KN | 3250 KN |

| 146 |

|

628/5 2Z | 11 mm | 5 mm | 4 mm | 0.0014 kg | 0.26 KN | 0.64 KN |

| 147 |

|

608 2RSR | 22 mm | 8 mm | 7 mm | 0.01 kg | 1370 KN | 3250 KN |

| 148 |

|

638/5 2Z | 11 mm | 5 mm | 5 mm | 0.0016 kg | 0.26 kN | 0.64 KN |

| 149 |

|

608 2Z | 22 mm | 8 mm | 7 mm | 0.011 kg | 1370 KN | 3250 KN |

| 150 |

|

619/5 2Z | 13 mm | 5 mm | 4 mm | 0.0025 kg | 0.335 KN | 0.884 KN |

| 151 |

|

609 | 24 mm | 9 mm | 7 mm | 0.015 kg | 1630 KN | 3650 KN |

| 152 |

|

619/5 | 13 mm | 5 mm | 4 mm | 0.0025 kg | 0.335 KN | 0.884 KN |

| 153 |

|

609 2RSR | 24 mm | 9 mm | 7 mm | 0.016 kg | 1630 KN | 3650 KN |

| 154 |

|

625 | 16 mm | 5 mm | 5 mm | 0.005 kg | 0.38 KN | 1.14 KN |

| 155 |

|

609 2Z | 24 mm | 9 mm | 7 mm | 0.016 kg | 1630 KN | 3650 KN |

| 156 |

|

625 2Z | 16 mm | 5 mm | 5 mm | 0.005 kg | 0.38 KN | 1.14 KN |

| 157 |

|

629 | 26 mm | 9 mm | 8 mm | 0.02 kg | 1960 KN | 4550 KN |

| 158 |

|

635 | 19 mm | 5 mm | 6 mm | 0.0085 kg | 0.95 KN | 2.34 KN |

| 159 |

|

635 2RS1 | 19 mm | 5 mm | 6 mm | 0.009 kg | 0.95 KN | 2.34 KN |

| 160 |

|

629 2RSR | 26 mm | 9 mm | 8 mm | 0.021 kg | 1960 KN | 4550 KN |

| 161 |

|

635 RS1 | 19 mm | 5 mm | 6 mm | 0.009 kg | 0.95 KN | 2.34 KN |

| 162 |

|

629 2Z | 26 mm | 9 mm | 8 mm | 0.021 kg | 1960 KN | 4550 KN |

| 163 |

|

61800 | 19 mm | 10 mm | 5 mm | 0.006 kg | 590 KN | 1450 KN |

| 164 |

|

635 2RZ | 19 mm | 5 mm | 6 mm | 0.009 kg | 0.95 KN | 2.34 KN |

| 165 |

|

61800 2RSR | 19 mm | 10 mm | 5 mm | 0.006 kg | 590 KN | 1450 KN |

| 166 |

|

635 RZ | 19 mm | 5 mm | 6 mm | 0.009 kg | 0.95 KN | 2.34 KN |

| 167 |

|

61800 2Z | 19 mm | 10 mm | 5 mm | 0.006 kg | 590 KN | 1450 KN |

| 168 |

|

635 2Z | 19 mm | 5 mm | 6 mm | 0.0093 kg | 0.95 KN | 2.34 KN |

| 169 |

|

61900 | 22 mm | 10 mm | 6 mm | 0.01 kg | 840 KN | 2200 KN |

| 170 |

|

628/6 2Z | 13 mm | 6 mm | 5 mm | 0.0026 kg | 0.35 KN | 0.88 KN |

| 171 |

|

635 Z | 19 mm | 5 mm | 6 mm | 0.0093 kg | 0.95 KN | 2.34 KN |

| 172 |

|

618/6 | 13 mm | 6 mm | 3.5 mm | 0.002 kg | 0.224 kN | 0.715 kN |

| 173 |

|

619/6 2Z | 13 mm | 6 mm | 5 mm | 0.0039 kg | 0.27 KN | 0.884 KN |

| 174 |

|

61900 2RSR | 22 mm | 10 mm | 6 mm | 0.01 kg | 840 KN | 2200 KN |

| 175 |

|

619/6 | 15 mm | 6 mm | 5 mm | 0.0039 kg | 0.27 KN | 0.884 KN |

| 176 |

|

61900 2Z | 22 mm | 10 mm | 6 mm | 0.01 kg | 840 KN | 2200 KN |

| 177 |

|

6000 | 26 mm | 10 mm | 8 mm | 0.019 kg | 1960 KN | 4550 KN |

| 178 |

|

626 | 19 mm | 6 mm | 6 mm | 0.0081 kg | 0.95 KN | 2.34 KN |

| 179 |

|

6000 2RSR | 26 mm | 10 mm | 8 mm | 0.02 kg | 1960 KN | 4550 KN |

| 180 |

|

626 2RSH | 19 mm | 6 mm | 6 mm | 0.0083kg | 0.95 KN | 2.34 KN |

| 181 |

|

6000 2Z | 26 mm | 10 mm | 8 mm | 0.02 kg | 1960 KN | 4550 KN |

| 182 |

|

626 RSH | 19 mm | 6 mm | 6 mm | 0.0083 kg | 0.95 KN | 2.34 KN |

| 183 |

|

6200 | 30 mm | 10 mm | 9 mm | 0.031 kg | 2600 KN | 6000 KN |

| 184 |

|

626 2RSL | 19 mm | 6 mm | 6 mm | 0.0083 kg | 0.95 KN | 2.34 KN |

| 185 |

|

618/7 | 14 mm | 7 mm | 3.5 mm | 0.0022 kg | 0.26 KN | 0.78 KN |

| 186 |

|

6200 2RSR | 30 mm | 10 mm | 9 mm | 0.032 kg | 2600 KN | 6000 KN |

| 187 |

|

626 RSL | 19 mm | 6 mm | 6 mm | 0.0083 kg | 0.95 KN | 2.34 KN |

| 188 |

|

6200 2Z | 30 mm | 10 mm | 9 mm | 0.032 kg | 2600 KN | 6000 KN |

| 189 |

|

626 2Z | 19 mm | 6 mm | 6 mm | 0.0088 kg | 0.95 KN | 2.34 KN |

| 190 |

|

628/7 2Z | 14 mm | 7 mm | 5 mm | 0.0031 kg | 0.4 KN | 0.956 KN |

| 191 |

|

619/7 2Z | 17 mm | 7 mm | 5 mm | 0.0049 kg | 0.375 KN | 1.06 KN |

| 192 |

|

62200 2RSR | 30 mm | 10 mm | 14 mm | 0.048 kg | 2600 KN | 6000 KN |

| 193 |

|

626 Z | 19 mm | 6 mm | 6 mm | 0.0088 kg | 0.95 KN | 2.34 KN |

| 194 |

|

619/7 | 17 mm | 7 mm | 5 mm | 0.0049 kg | 0.375 KN | 1.06 KN |

| 195 |

|

6300 | 35 mm | 10 mm | 11 mm | 0.055 kg | 3450 KN | 8150 KN |

| 196 |

|

607 | 19 mm | 7 mm | 6 mm | 0.0076 kg | 0.95 KN | 2.34 KN |

| 197 |

|

6300 2RSR | 35 mm | 10 mm | 11 mm | 0.057 kg | 3450 KN | 8150 KN |

| 198 |

|

607 2RSH | 19 mm | 7 mm | 6 mm | 0.0078 kg | 0.95 KN | 2.34 KN |

| 199 |

|

6300 2Z | 35 mm | 10 mm | 11 mm | 0.057 kg | 3450 KN | 8150 KN |

| 200 |

|

607 RSH | 19 mm | 7 mm | 6 mm | 0.0078 kg | 0.95 KN | 2.34 KN |

Features and advantages of QIBR standard deep groove ball bearings

QIBR standard deep groove ball bearings are engineered to address critical operational demands in various industrial fields, offering the following key advantages:

1. Low friction and smooth operation

The point contact between the rolling elements and raceways minimizes friction, resulting in low noise, reduced energy consumption, and smooth operation.

2. High-speed capability

The optimized geometry of rolling elements and raceways ensures stability and low thermal generation at high speeds, making them suitable for high-speed machinery.

3. Enhanced sealing performance

Equipped with optional seals, these bearings prevent contamination and retain lubricants, extending operational lifespan.

4. Compact and simple design

The straightforward structure, consisting of an inner ring, outer ring, rolling elements, and a cage, ensures ease of manufacturing, installation, and maintenance.

5. High load capacity

Capable of handling substantial radial loads along with moderate axial loads, offering versatility across numerous applications.

Performance enhancements for QIBR standard deep groove ball bearings

1. Lubrication optimization

Advanced lubricants, such as synthetic or nano-lubricants, can reduce wear and friction, enhancing overall efficiency and durability. Proper application techniques further ensure optimal performance.

2. Raceway optimization

Precision machining of the raceway geometry, along with improved surface finish, minimizes frictional losses and enhances operational efficiency.

3. Enhanced rolling elements

Utilizing high-precision rolling elements, such as ceramic balls, improves surface hardness and reduces wear, resulting in superior performance under demanding conditions.

4. Corrosion resistance

For applications in aggressive environments, materials such as stainless steel, corrosion-resistant coatings, or surface treatment technologies can significantly improve durability.

Primary application fields of QIBR standard deep groove ball bearings

1. Electric motors

Integral to motor assemblies, supporting the rotor for stable, efficient rotation, particularly in small and micro-motors.

2. Automotive systems

Wheel hubs: Designed for heavy radial load support in wheel assemblies.

Engine components: Applied in crankshafts, camshafts, and similar components for smooth rotation under varying loads.

Transmissions: Ensures reliable operation of gears within automotive transmission systems.

3. Industrial machinery

Machine tools: Used in spindles and feed systems for high-speed, precise operation.

Power transmission systems: Integrated into sprockets and pulleys for efficient power transfer.

Pumps and compressors: Withstand heavy loads and ensure durability in hydraulic and pneumatic systems.

4. Household appliances

Washing machines: Supports the drum and motor for consistent and smooth operation.

Electric fans: Maintains stability and efficiency in motor systems.

Refrigeration and air conditioners: Deployed compressors for prolonged service life and reliable performance.

5. Rail transportation

Rail vehicles: Designed for wheelsets in locomotives and carriages, ensuring reliable operation under high loads and at varying speeds.