GE30PB

- Inner diameter:

- 1.181"/30 mm

- Outer diameter:

- 2.165"/55 mm

- Width:

- 1.457"/37 mm

- Mass:

- 0.838 lbs

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - GE30PB

Description

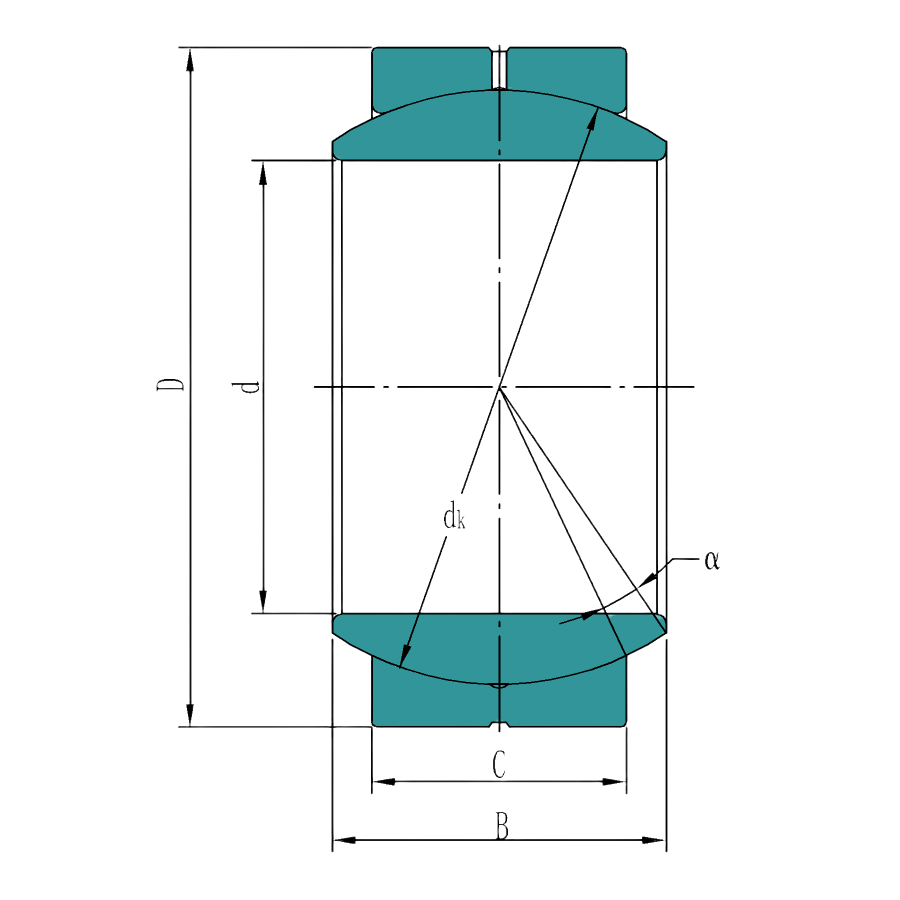

QIBR - GE30PB Joint Bearing Advantages and Applications

GE30PB Joint Bearing, has self-aligning ability, wear resistance, Shaft (d) is 1.181"/30 mm, Outer diameter (D) is 2.165"/55 mm, Width (B) is 1.457"/37 mm, Width (C) is 0.984''/25 mm, Weight is 0.838 lbs, suitable for crane transmission systems, bulldozers and mixers, etc., and is the most widely used bearing in working conditions that require high self-aligning ability.

QIBR - GE30PB Joint Bearing Characteristics

GE30PB Joint Bearing, long life, low production cost, high cost performance. GE30PB Joint Bearing, can withstand radial load, certain axial load and overturning moment, suitable for mechanical equipment with high durability requirements.

GE30PB Joint Bearings Features and Advantages

Reliability: High load capacity and durability reduce failures and downtime.

Structural Design: The inner and outer rings feature spherical and inner spherical surfaces, allowing rotation and swinging at any angle.

Load Capacity: Capable of withstanding significant radial and axial loads, suitable for high-stress and heavy-duty applications.

Self-Aligning Function: Equipped with self-aligning characteristics, it can automatically adjust during installation errors or movement, ensuring smooth operation.

Application: Widely used in fields such as engineering hydraulic cylinders, forging machine tools, construction machinery, automation equipment, automotive shock absorbers, and hydraulic machinery.

QIBR - GE30PB Joint Bearings Optimization

High-performance materials: Bearing materials can be replaced based on different working conditions, such as FRP, bearing steel, stainless steel, and other materials.

Surface Treatment: The bearing surface can be treated according to customer requirements, including phosphating, galvanizing, chrome plating, and lining, padding, or spraying on the sliding surfaces.

More customization: QIBR can design and optimize bearings based on customer usage conditions and needs.

QIBR - GE30PB Joint Bearings Quality Control

Dimension measurement: Various professional high-precision instruments are used to measure multiple dimensions of the bearing, with the highest precision reaching 0.001mm.

Rotational Accuracy: A dial gauge measures small surface defects or deviations, with a measurement accuracy of up to 0.001mm.

Hardness measurement: Use a hardness tester to measure the surface hardness of the guide rail, with a measurement accuracy of ±0.5HRC.

Metallographic Analysis: The internal metallographic structure of the metal is analyzed using a professional metallographic microscope.

Noise Monitoring: Vibration data is obtained by monitoring the vibrations during operation with a vibration meter.

Geometric tolerance: Use a profiler to measure the geometry and relative position of the guide rail.

Raw material control: Procurement of steel and parts from ISO 14001 certified suppliers ensures product stability while promoting sustainable development.

Features & Benefits

Joint bearings, also known as spherical plain bearings or spherical bearings, are mechanical components designed to accommodate misalignment between two parts. They consist of an inner ring with a spherical surface and an outer ring with a concave spherical bore. This design allows for smooth rotation and movement in multiple directions, making them suitable for applications where there are angular misalignments or oscillating movements. Joint bearings are commonly used in various industrial machinery and automotive applications, such as steering systems, suspension systems, and linkage mechanisms.

Downloads