QIBR Linear Roller Bearings Delivered to a Customer in Houston, USA, to Enhance Lifespan and Stability in Logistics Sorting Conveyors

- Continent

- North America

- Country

- The United States

- Date

- 2016-03-27

- Categories

-

Linear Roller Bearings

- Applications

- Logistics - Sorting Conveyors

Products Used

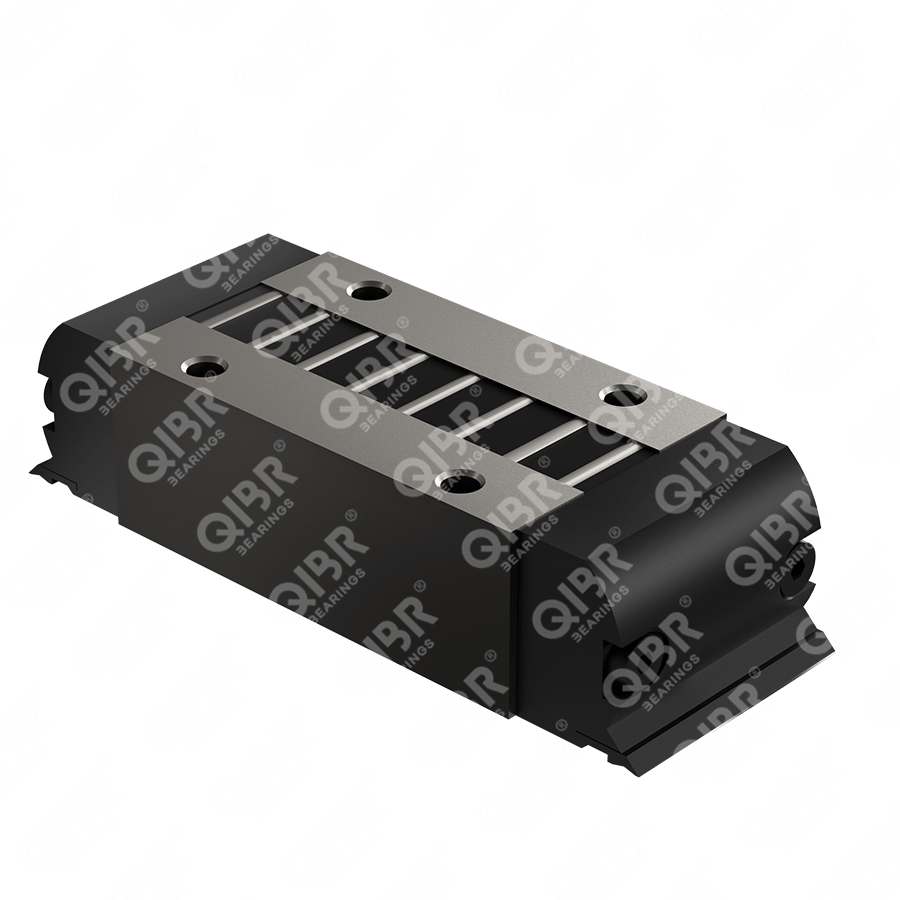

Linear Roller Bearings

1. Improved Operating Precision: The RUS 85280 linear roller bearing uses low-friction materials to significantly reduce friction, providing high-precision linear motion. The conveyor can follow a predetermined path during operation, avoiding deviations or irregular movements. This precision ensures accurate positioning and sorting of items during transportation.

2. Enhanced Load Capacity: The RUS 85280 linear roller bearing is designed to withstand significant loads, made from high-strength materials with excellent mechanical properties. It can support heavy weights and impacts, enhancing overall load capacity and maintaining stability during the sorting and transportation of heavy items.

3. Reduced Wear and Maintenance: The materials and design of the RUS 85280 linear roller bearing effectively minimize wear, extending its lifespan. The simple design with fewer components reduces potential failure points and complexity, making maintenance easier and allowing for quick identification and resolution of potential issues, thus lowering maintenance costs and frequency.

Additional Notes:

The customer in the USA decided to purchase QIBR's RUS 85280 linear roller bearings to meet their needs for enhancing equipment lifespan and operational stability in logistics sorting conveyors. QIBR employs advanced engineering technology and strict quality control standards, ensuring that the precision manufacturing process allows the guides to maintain outstanding operational stability even under heavy loads, minimizing wear. The RUS 85280 linear roller bearings use high-quality steel, offering excellent wear and corrosion resistance, which is especially important for logistics equipment frequently used in variable working environments. These guides can endure prolonged heavy-duty operation without damage, significantly extending their service life.