QIBR Slewing Bearings Delivered to Customer in New York, USA for Filling Machine Rotation Accuracy and Stability Improvement

- Continent

- North America

- Country

- The United States

- Date

- 2016-08-22

- Categories

-

Slewing Bearing

- Applications

- Filling Machine

Products Used

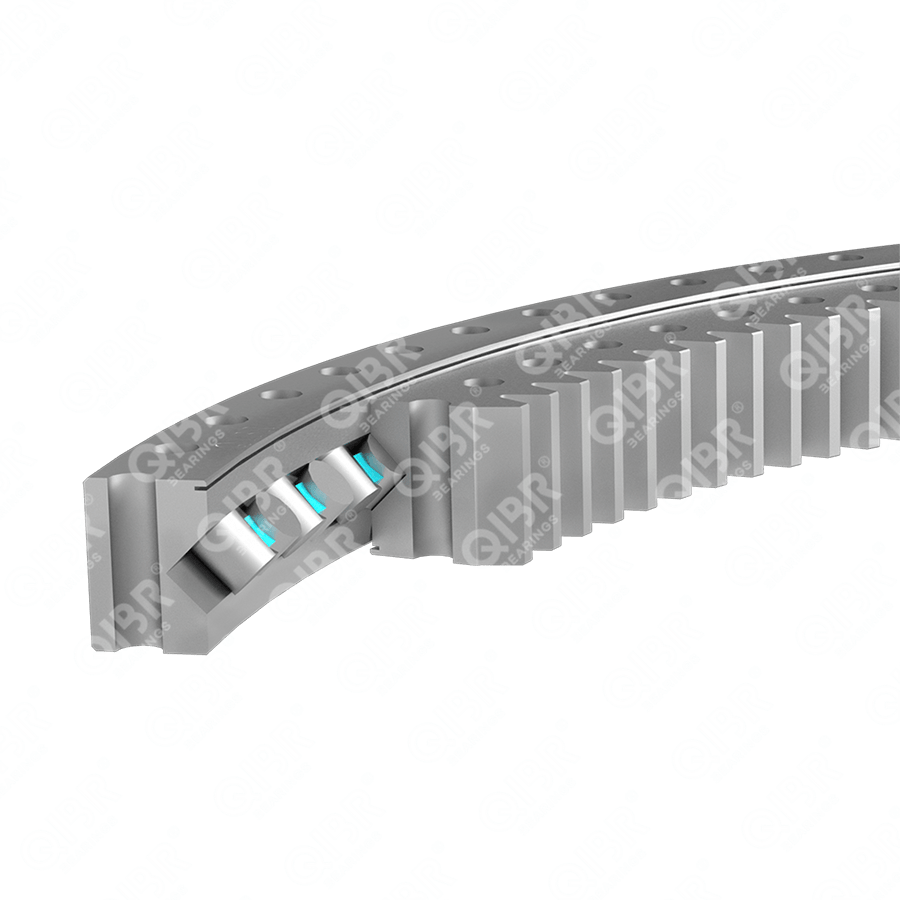

Slewing Bearing

1. High load capacity: The 113.28.800 slewing bearings distribute the load across multiple contact points, increasing the contact area. This effectively disperses the load applied to the bearing, reducing localized stress and improving load-bearing capacity. The filling machine can operate stably under high loads, ensuring production efficiency and product quality.

2. Precise Positioning: The 113.28.800 slewing bearings are processed with high precision, ensuring that the dimensions and shapes of all components meet strict tolerance requirements. During operation, they maintain good concentricity and roundness, improving positioning accuracy. This ensures that bottles are accurately aligned during the filling process, reducing material waste and improving production efficiency.

3. Reduced Vibration and Noise: The 113.28.800 slewing bearings have high rigidity, effectively resisting external impacts and vibrations. They maintain the stability of the filling machine during operation, reducing noise caused by vibrations. This enhances operational comfort and reduces the environmental impact.

Additional Notes:

The customer in the USA decided to purchase the QIBR 113.28.800 slewing bearings to enhance the rotation accuracy and stability of the filling machine. The 113.28.800 slewing bearings are made with precision machining and high-quality materials to ensure stable long-term operation under high-speed and high-load conditions. Through advanced manufacturing processes and quality control, QIBR ensures that the bearings are accurately aligned, minimizing deviations during operation and ensuring the efficient operation of the filling machine. The 113.28.800 slewing bearings use high-performance materials and advanced heat treatment technology, providing exceptional load-bearing capacity and the ability to withstand rotational inertia, impact forces, and loads during operation. This reduces machine wear and extends the service life of the filling machine, improving overall operational efficiency and economic benefits.