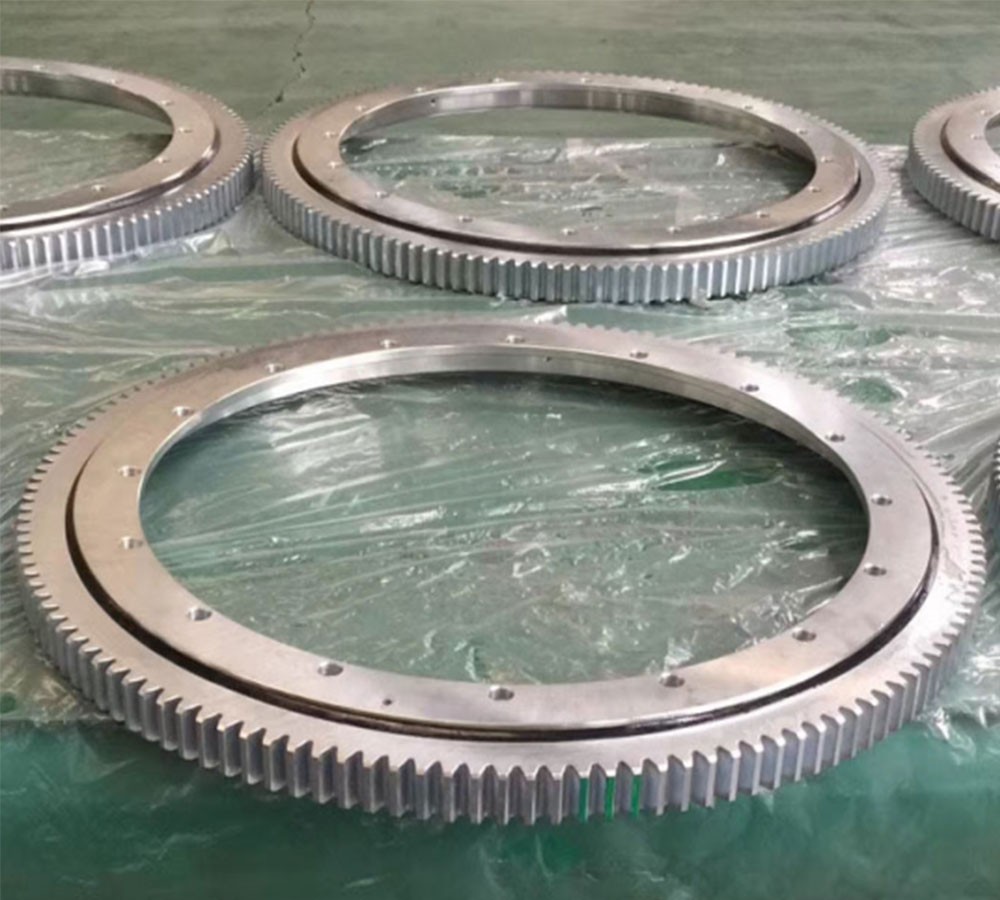

QIBR Slewing Rings Delivered to a Customer in Sydney, Australia, for Bucket Wheel Excavators to Enhance Stability and Durability

- Continent

- Oceania

- Country

- Australia

- Date

- 2016-06-13

- Categories

-

Slewing Bearing

- Applications

- Mining Bucket Wheel Excavators

Products Used

slewing bearing

1. Strong load-carrying capacity: The 112.25.630 slewing bearing can simultaneously support significant radial, axial, and overturning moments. Its large-diameter rolling elements increase the contact area, enhancing rigidity and minimizing deformation-related errors. This high load capacity ensures the stability and safety of the bucket wheel excavator.

2. Wear Resistance: Constructed from high-strength steel and subjected to precision machining and heat treatment, the 112.25.630 slewing bearing offers excellent wear resistance and impact resistance. It maintains stability and durability even under high load conditions.

3. High Precision: The 112.25.630 slewing bearing provides smooth rotational motion with minimal friction loss. Its manufacturing process adheres to strict standards, ensuring geometric accuracy and dimensional precision, allowing the excavator to maintain low energy consumption under high loads.

Additional Notes:

In the highly competitive mining market, the Australian customer recognized the importance of the QIBR 112.25.630 slewing bearing in enhancing the stability and durability of their bucket wheel excavators. As a critical component, this bearing provides reliable support and precise motion control under extreme conditions, improving overall performance. QIBR utilizes high-quality alloy steel and advanced material technology to ensure the bearing's durability under high loads and harsh environments, capable of withstanding significant impact forces while resisting corrosion and wear. The precision machining of the 112.25.630 slewing bearing results in a low friction coefficient, reducing heat generation and lowering the risk of excavator failure.