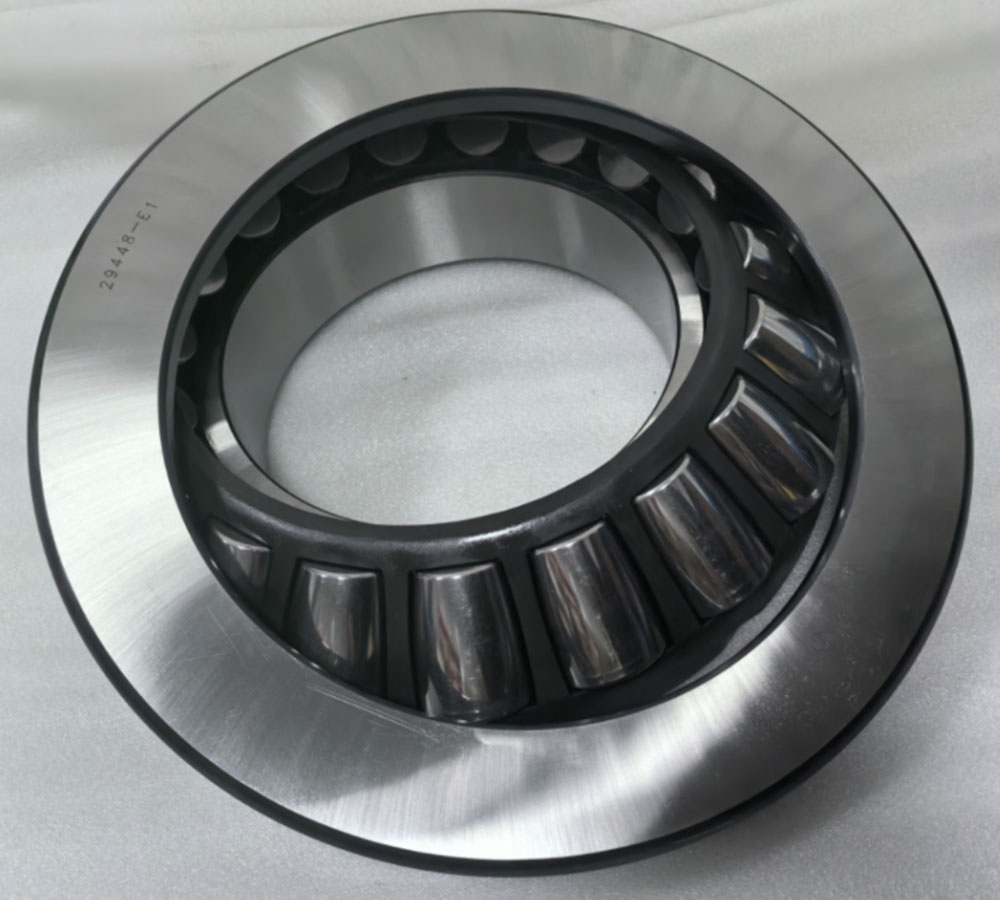

QIBR Spherical Roller Thrust Bearing Delivered to a Client in Cali, Colombia, Enhancing the Stability and Safety of Crane Hoisting Mechanisms

- Continent

- Sourth America

- Country

- Columbia

- Date

- 2016-04-24

- Categories

-

Spherical roller thrust bearings

- Applications

- Crane Hoisting Mechanism

Products Used

Spherical Roller Thrust Bearing

1. High load capacity: The 29448 E spherical roller thrust bearing uses spherical rollers as rolling elements, distributing the load over a larger contact surface, which allows for more even force distribution and the ability to handle higher loads. It can support loads in multiple directions, ensuring stability and safety during heavy-duty operations in crane hoisting mechanisms.

2. Self-Aligning Capability: The rollers in the 29448 E spherical roller thrust bearing form a spherical contact with the bearing seat. This allows the bearing to effectively accommodate slight misalignments, enabling the rollers to roll freely within a certain range while maintaining good contact. It adjusts for installation errors or misalignments during operation, reducing wear and vibration caused by misalignment.

3. Adaptability to High Speeds: The 29448 E spherical roller thrust bearing has excellent heat dissipation, preventing overheating during high-speed operation. Made from high-strength, wear-resistant materials, it can withstand mechanical stresses at high speeds, ensuring stable performance even under high-speed conditions.

Additional Notes:

After thorough investigation and evaluation, the client in Colombia chose QIBR's 29448 E spherical roller thrust bearing to meet the crane hoisting mechanism's requirements for stability and safety. QIBR is committed to strictly adhering to international quality management systems, ensuring that every 29448 E spherical roller thrust bearing meets high production standards. This bearing excels in load capacity, tilt resistance, and low friction coefficient, making it an ideal solution for crane applications, where it effectively enhances stability and improves safety. It ensures reliability during heavy-load operations, maintaining consistent performance.