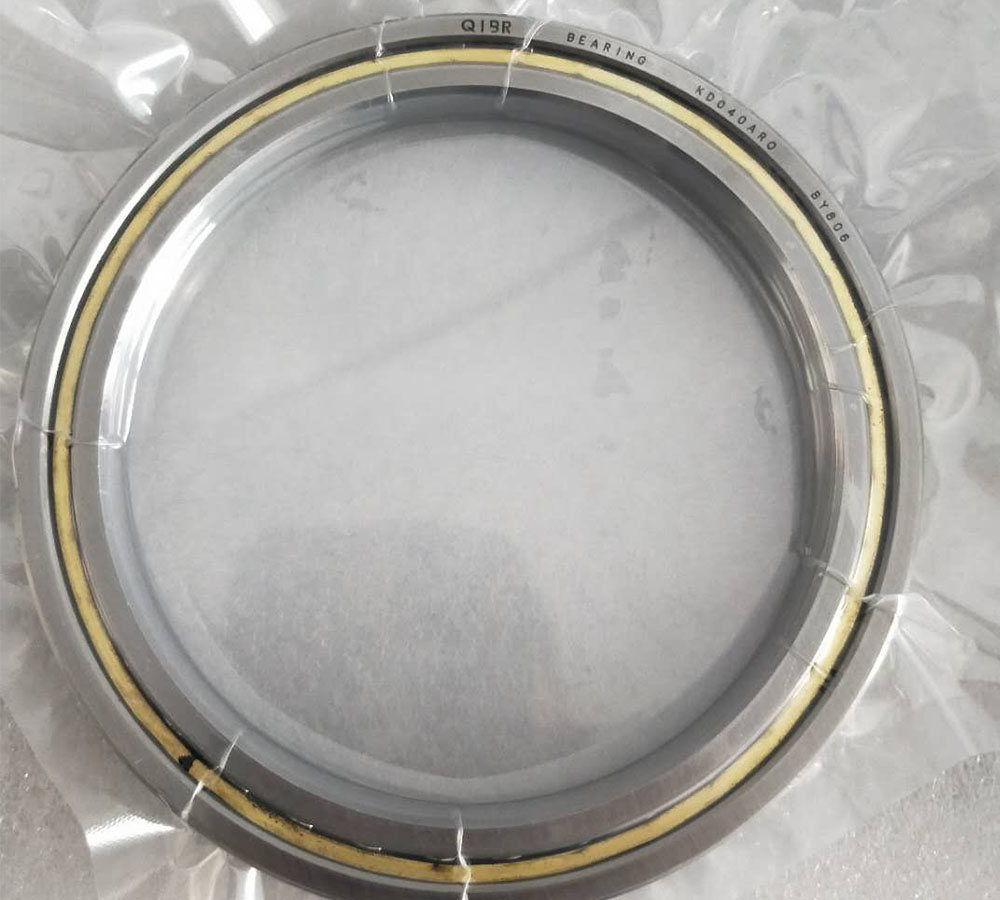

QIBR Thin-Section Ball Bearings Delivered to Madrid, Spain for Improved Precision and Durability in Conveyor Line Robotic Arms

- Continent

- Europe

- Country

- Spain

- Date

- 2016-09-19

- Categories

-

Thin-Section Ball Bearing

- Applications

- Conveyor Line Robotic Arm

Products Used

Thin-Section Ball Bearing

1. Lightweight Design: The QKD040AR0 thin-section ball bearing features a very thin radial and axial section, maintaining strength and load capacity while reducing weight. This improves the robotic arm's mobility, responsiveness, and energy efficiency. It is ideal for installations in space-constrained environments, allowing the robotic arm to operate in narrow workspaces and adapt to complex mechanical structures.

2. High Load Capacity: The QKD040AR0 thin-section ball bearing accommodates more steel balls, improving load distribution, reducing deformation, and increasing its load-bearing capacity. It has low friction characteristics, enabling stable operation at high speeds, making it suitable for the high-speed and precision requirements of conveyor line robotic arms.

3. Stability: The QKD040AR0 thin-section ball bearing maintains low vibration and noise levels during operation, enhancing production efficiency and product quality. It has a long service life, reducing maintenance costs and downtime, and improving the overall reliability of the production line.

Additional Notes:

After evaluating several bearing suppliers, the Spanish customer ultimately chose QIBR QKD040AR0 thin-section ball bearings to meet the high precision and durability requirements of their conveyor line robotic arms. The bearings are manufactured using precise processing techniques, ensuring extremely high dimensional accuracy and surface finish, which helps reduce errors during the robotic arm's high-speed movements, ensuring high-precision operation. The QKD040AR0 bearings are made from high-quality materials and undergo advanced heat treatment and surface processing techniques, which enhance wear resistance, corrosion resistance, and fatigue resistance. This improves the positioning accuracy and consistency of movements in the robotic arm, boosting overall production efficiency.