QIBR Angular Contact Ball Bearing and Thin-Wall Ball Bearing Supplied to Paris, France, Enhancing Stability and Precision in Machine Tool Guideways

- Continent

- Europe

- Country

- France

- Date

- 2016-08-30

- Applications

- Machine Tool Guideways

Products Used

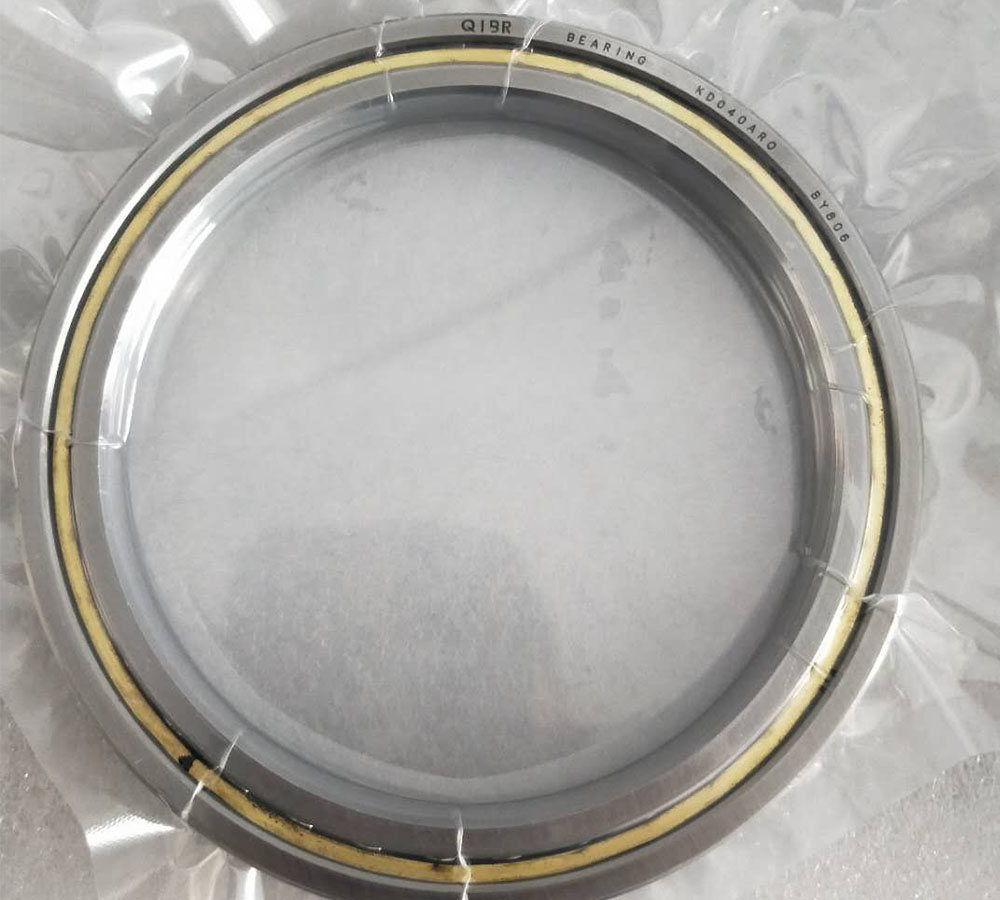

Thin-Section Ball Bearing

1. Lightweight Design: The QKD040AR0 thin-wall ball bearing has a compact, thin-walled structure that reduces overall weight and space requirements. This design flexibility is especially beneficial for machine tool guideways requiring frequent movement and position adjustments, improving operational flexibility.

2. High-Speed Capability: Optimized to minimize friction losses, the QKD040AR0 is suited for high-speed operation, ensuring efficient and precise machining in high-speed conditions.

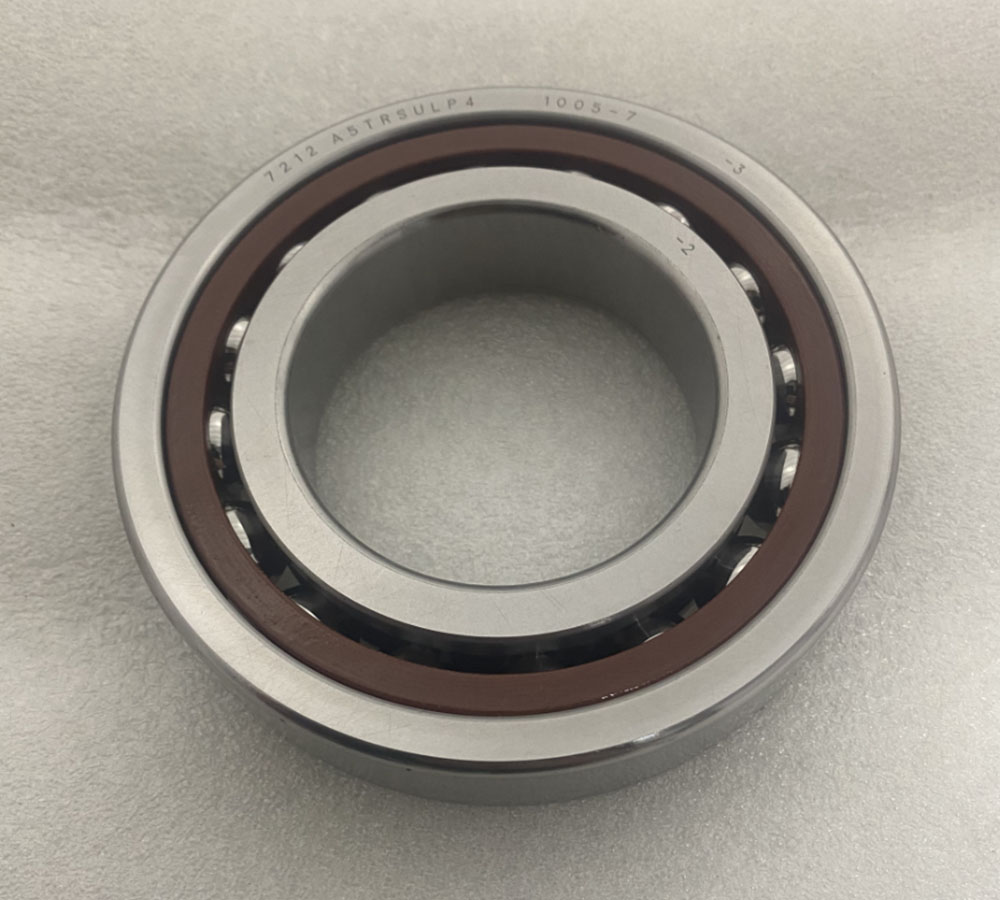

Angular Contact Ball Bearing

1. High Precision: The 7212 angular contact ball bearing is designed with a specific contact angle, enabling it to bear both radial and axial loads simultaneously, ideal for high-precision, high-speed conditions. This enhances the accuracy of machining processes on the machine tool guideways, improving production quality.

2. High Rigidity: With high rigidity, the 7212 bearing maintains minimal deformation under heavy loads, supporting the machine’s stability and machining precision.

3. Wear Resistance: Made with high-strength materials and advanced manufacturing processes, the 7212 bearing offers superior wear resistance and fatigue strength, extending its lifespan and reducing maintenance frequency.

Additional Notes:

The French client selected QIBR’s 7212 angular contact ball bearing and QKD040AR0 thin-wall ball bearing to improve stability and precision in their machine tool guideways. With advanced manufacturing techniques and strict quality control, both bearings offer exceptional accuracy and stability. QIBR bearings effectively reduce mechanical vibration, enhancing the machine’s precision and operational efficiency. They continue to perform reliably under high load and complex operating conditions, demonstrating excellent wear resistance, corrosion resistance, and fatigue strength. With these bearings, the machine tool guideways can complete more high-precision machining tasks in less time, boosting production capacity and revenue.