QIBR Angular Contact Ball Bearings and Deep Groove Ball Bearings Delivered to Toronto, Canada, for Coal Augers to Enhance Safety and Stability

- Continent

- North America

- Country

- Canada

- Date

- 2016-07-17

- Applications

- Coal Augers

Products Used

Deep Groove Ball Bearing

1. High Load Capacity: The 623 deep groove ball bearings can handle both radial and axial loads, meeting the varied operational demands of coal augers and increasing their flexibility.

2. High-Speed Capability: These bearings are designed to operate stably under high-speed conditions, ensuring that the coal auger can quickly transport coal and improve overall operational efficiency.

3. Wear Resistance: Constructed from wear-resistant materials, the 623 deep groove ball bearings maintain good working conditions over prolonged use, reducing maintenance costs.

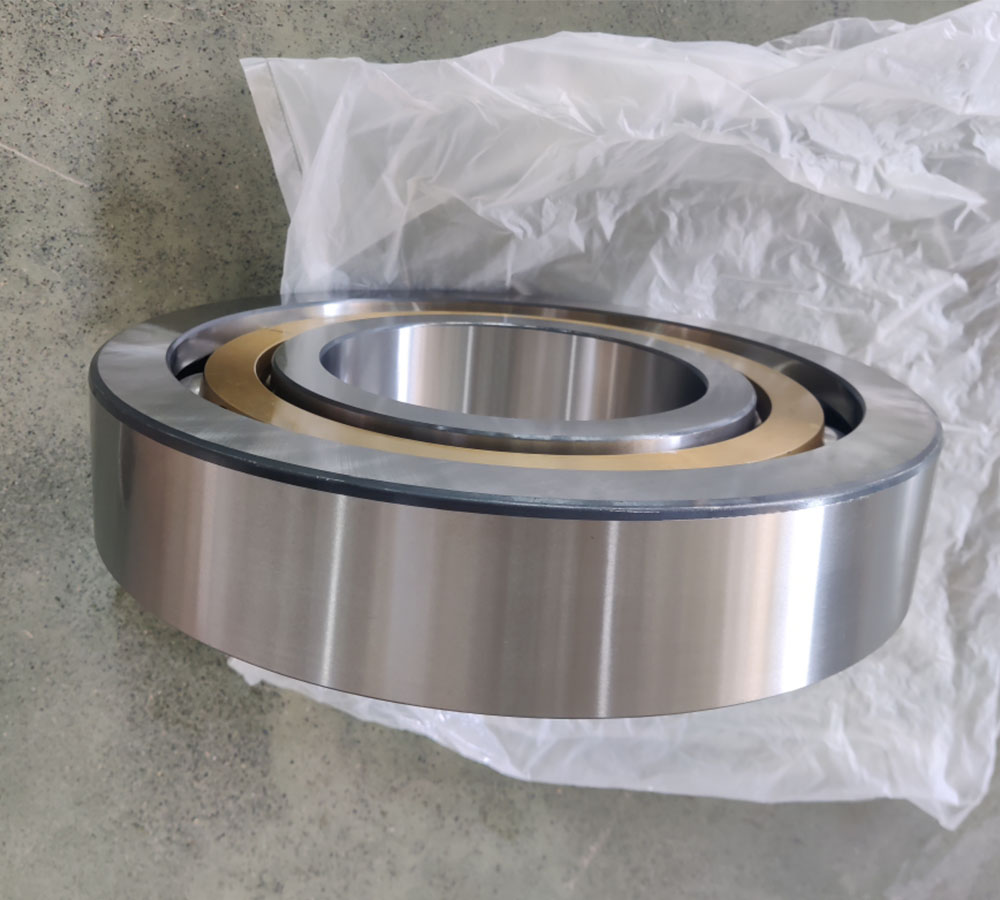

Angular Contact Ball Bearings

1. High Load Capacity: The QHCB71905C angular contact ball bearings can withstand significant radial and axial loads, ensuring overall stability during the high-load conditions encountered by coal augers.

2. High Precision: These bearings maintain high positioning accuracy and stability during high-speed operation, ensuring that the coal auger's work process is more precise and reliable, thus improving coal transportation efficiency.

3. High-Temperature Resistance: The QHCB71905C bearings exhibit excellent high-temperature performance, making them suitable for the high-temperature working environment of coal augers, ensuring long-term stability.

Additional Notes:

The Canadian client chose to procure QIBR's QHCB71905C angular contact ball bearings and 623 deep groove ball bearings to enhance the safety and stability of their coal augers. The QHCB71905C bearings are capable of supporting bi-directional loads, providing better stability and support during high-speed operations. The 623 deep groove ball bearings offer advantages such as simple structure, easy installation, and strong adaptability, effectively functioning under various working conditions by handling significant radial loads and some axial loads. QIBR bearings not only meet the high safety and stability requirements of coal augers but also provide reliable support and performance in high-load and high-speed working environments.