QIBR cylindrical roller bearings and deep groove ball bearings were delivered to a customer in Calgary, Canada, to enhance stability of hoisting cranes used in oil and gas extraction

- Continent

- North America

- Country

- Canada

- Date

- 2016-02-16

- Applications

- Oil and Gas Extraction,Hoisting Cranes

Products Used

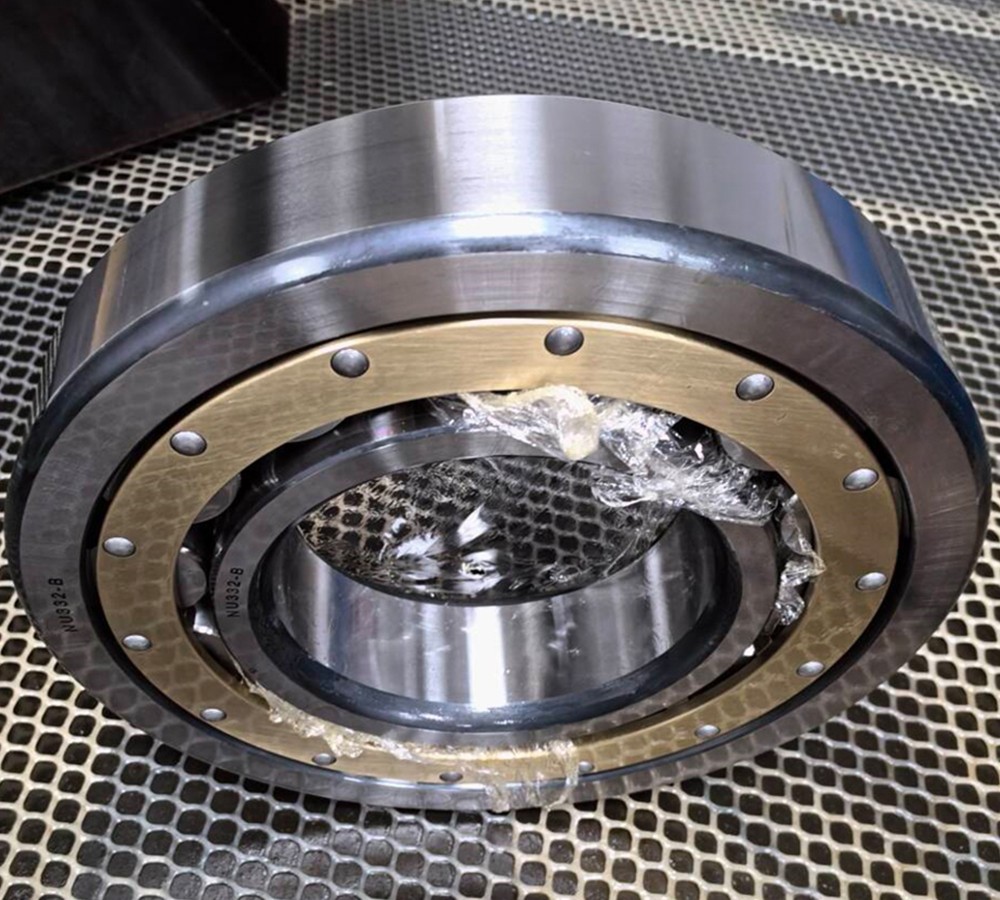

Cylindrical Roller Bearings

1. High load - bearing capacity : The NU 332 cylindrical roller bearing can withstand significant radial loads due to its line contact between the rollers and the inner/outer rings, effectively distributing the load and increasing bearing capacity. This design supports the weight of equipment and operational loads.

2. Impact Load Resistance : Made from high-strength, wear-resistant materials, these bearings exhibit excellent fatigue resistance and toughness, effectively resisting damage from impact loads. This reduces the risk of equipment failure and enhances overall safety.

Deep Groove Ball Bearings

1. High load - bearing capacity: The 6310 deep groove ball bearing can simultaneously support radial and some axial loads. Its ribbed design on both sides of the inner and outer rings prevents separation under axial forces, ensuring stable operation under various conditions.

2. High-speed performance : With point contact between the raceway and balls leading to minimal friction loss, this bearing reduces heat generation and improves speed capabilities. It is ideal for equipment requiring rapid movement or rotation, thereby enhancing operational efficiency.

Additional Notes:

The Canadian customer chose QIBR's NU 332 cylindrical roller bearings and 6310 deep groove ball bearings to meet safety and stability requirements for hoisting cranes in oil and gas extraction. QIBR products are manufactured from high-quality materials that provide excellent wear resistance and impact strength, ensuring long-term stable operation in harsh environments. Selecting QIBR bearings not only enhances the safety and stability of hoisting cranes but also offers significant economic benefits; the durability and reliability of QIBR bearings allow customers to reduce crane failures and maintenance frequency, lowering overall operational costs.