QIBR cylindrical roller bearings and tapered roller bearings were delivered to our customer in Frankfurt, Germany, to ensure stability and long life for wind turbine main shafts and pitch systems

- Continent

- Europe

- Country

- Germany

- Date

- 2016-03-15

- Applications

- wind turbines,wind turbines

Products Used

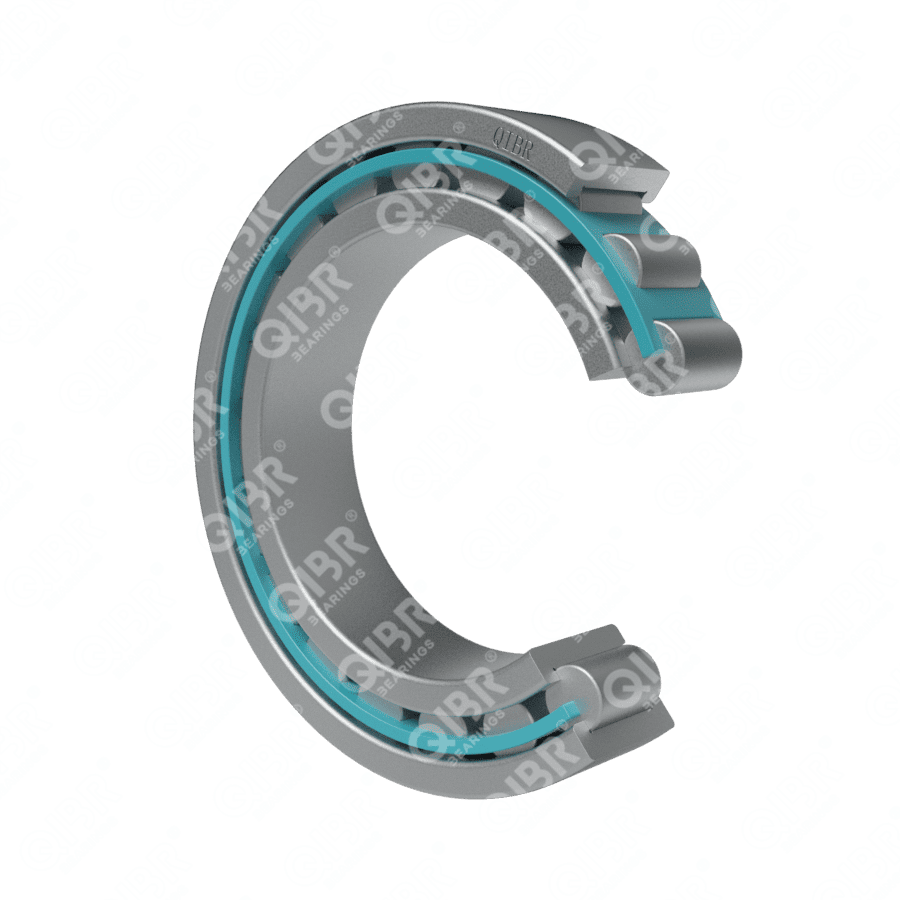

Cylindrical Roller Bearings

1. High load - bearing capacity : The contact between the roller and the raceway is line contact, which can effectively disperse the load and enable the bearing to withstand large radial loads. NJ 209 cylindrical roller bearings perform well when subjected to heavy loads and impact loads.

2. Low friction loss : The geometry of the cylindrical rollers is optimized, and the ribs and roller end faces improve lubrication conditions, forming a more effective oil film and reducing friction. It helps to improve the efficiency of the variable pitch system, reduce energy loss, and improve the overall power generation efficiency.

Tapered roller bearing

1. High load - bearing capacity : The inner and outer ring raceways are tapered, and the contact between the roller and the raceway is line contact. The load can be more evenly distributed between the roller and the raceway, dispersing the load, reducing stress concentration, and improving the load capacity.

2. Superior rigidity and stability : The inclined contact angle of the 458-452D tapered roller bearing design provides higher rigidity, resists the overturning moment during rotation, and ensures the stability of the main shaft under high-speed operation, which is particularly important for large wind turbines.

Additional Notes:

The German customer decided to purchase NJ 209 cylindrical roller bearings and 458-452D tapered roller bearings from QIBR to meet the safety, stability and long life requirements of wind turbines. QIBR NJ 209 cylindrical roller bearings and 458-452D tapered roller bearings are both optimized and can withstand large radial and axial loads. Used in wind turbine main shafts and pitch systems and main shafts to ensure reliable operation under harsh working conditions. QIBR uses advanced materials and surface treatment technology to improve the wear resistance and fatigue resistance of bearings, extend the service life of products, reduce maintenance frequency, and reduce operating costs.