QIBR deep groove ball bearings and high-precision angular contact ball bearings were delivered to a customer in the UK to enhance the flexibility and performance of precision industrial robots.

- Continent

- Europe

- Country

- United Kingdom

- Date

- 2016-01-02

- Applications

- Precision industrial robots

Products Used

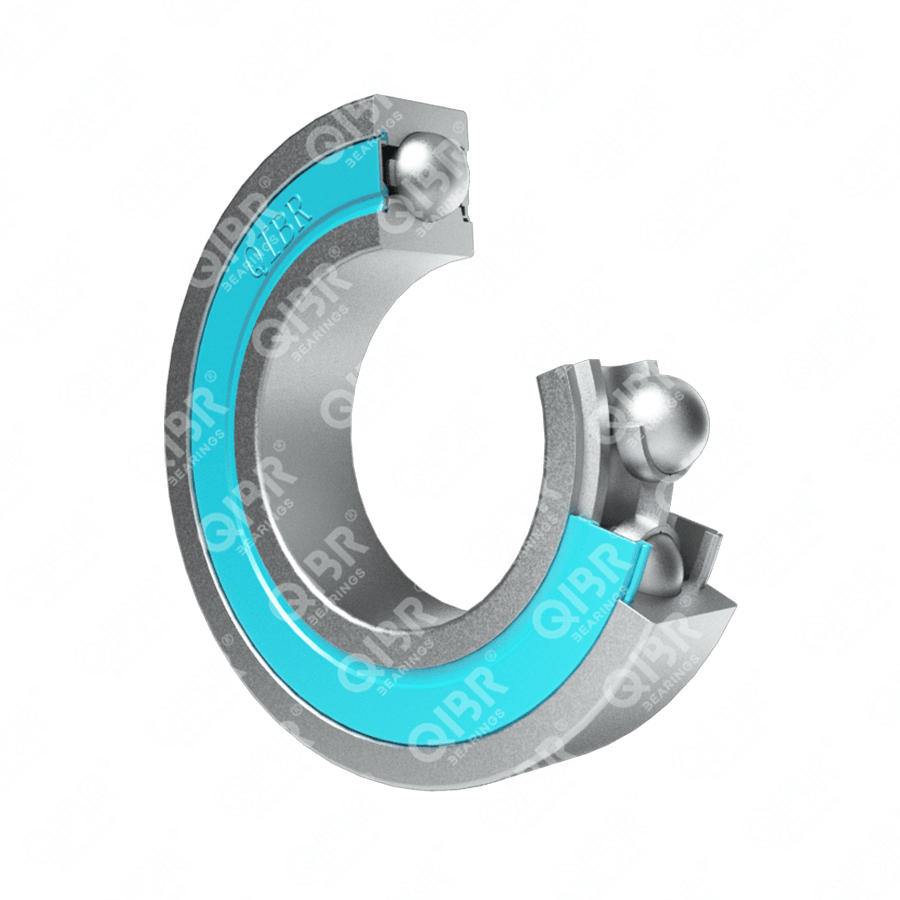

Deep Groove Ball Bearings

1. High Load Capacity: The 6308/2RS deep groove ball bearing can handle both radial and axial loads, making it suitable for the complex load requirements of industrial robots.

2. Low Friction Characteristics: Optimized design and high-precision manufacturing processes result in a low friction coefficient, maintaining stability during high-speed operation and enhancing overall efficiency.

3. Superior Sealing Performance: The 683/2RS features a double-sided sealing design that effectively prevents dust and contaminants from entering, extending the bearing's lifespan and reducing maintenance frequency.

High-Precision Angular Contact Ball Bearings

1. High Rigidity and Precision: Angular contact ball bearings can withstand significant axial loads, making them ideal for high-precision positioning applications in robotic joints.

2. Excellent Axial Positioning Capability: They maintain high stability and precision under axial loads, ensuring accurate movement of the robots.

3. Strong Durability: High-quality materials and manufacturing processes allow angular contact ball bearings to perform excellently under high loads and speeds, suitable for prolonged operation.

Additional Notes:

QIBR employs advanced manufacturing processes and equipment in bearing production, ensuring that its deep groove ball bearings and angular contact ball bearings exceed industry standards in size and geometry. This high precision guarantees stable performance under high speeds and heavy loads, significantly enhancing the operational efficiency and accuracy of industrial robots. The UK customer opted for QIBR's high-precision deep groove ball bearings and angular contact ball bearings as an equivalent alternative to NACHI bearings to meet their requirements for flexibility and high performance in industrial robots.