QIBR delivered crossed roller bearings and precision angular contact ball bearings to a customer in the United States for use in aerospace propulsion systems, ensuring stability and reliability

- Continent

- North America

- Country

- The United States

- Date

- 2016-01-19

- Categories

-

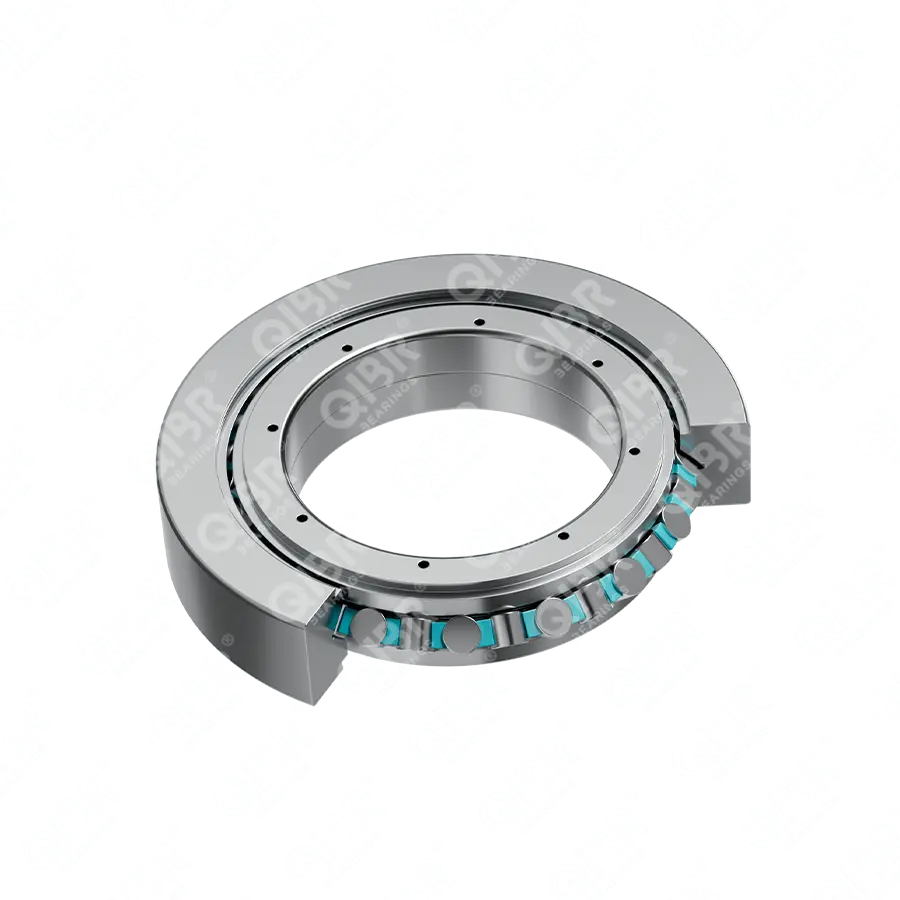

Cross Roller Bearing

Angular Contact Ball Bearing

- Applications

- Aerospace propulsion systems

Products Used

Crossed roller bearings

1. High load - bearing capacity: Crossed roller bearings can withstand significant radial and axial loads simultaneously, with a structure that effectively distributes the loads to ensure system stability. Precision angular contact ball bearings also have excellent load-bearing capacity, capable of handling high axial and radial loads.

2. High Precision and Stability : QIBR's crossed roller bearings and precision angular contact ball bearings utilize advanced manufacturing processes to ensure extremely high geometric accuracy and surface finish. This high-precision design reduces vibration and noise, enhancing the stability of propulsion systems during operation.

3. High-Temperature and Corrosion Resistance : Aerospace propulsion systems often face high-temperature, high-pressure, and corrosive environments. QIBR's crossed roller bearings and precision angular contact ball bearings use high-strength materials and special surface treatments to ensure stable operation under these extreme conditions, extending service life.

Additional Notes:

QIBR's bearing designs have high rigidity, effectively resisting deformation and maintaining stability under heavy loads. This rigidity is crucial for aerospace propulsion systems, as it directly impacts aircraft control and safety. Due to their excellent durability and reliability, QIBR's bearings can reduce replacement frequency, lowering maintenance and replacement costs, thereby improving overall economic benefits. This long-term reliability ensures the stability of aerospace propulsion systems during critical missions. By selecting QIBR's high-precision deep groove ball bearings and high-precision angular contact ball bearings, the U.S. customer can effectively replace NTN bearings, meeting the stringent requirements of aerospace propulsion systems in terms of safety, stability, and adaptability to harsh environments.