QIBR delivered double-row ball slewing bearings to a customer in Canada for use in high-capacity tower cranes, enhancing safety and stability

- Continent

- North America

- Country

- Canada

- Date

- 2016-01-21

- Categories

-

Slewing Bearing

- Applications

- High-capacity tower cranes

Products Used

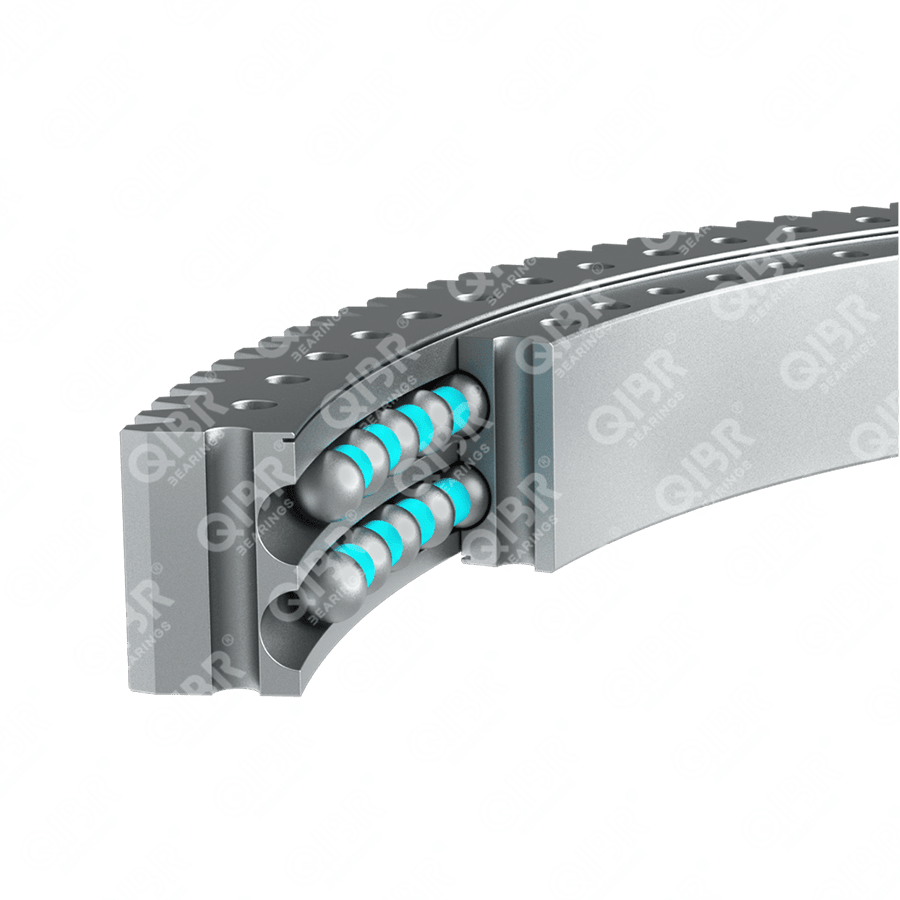

Double-row ball slewing bearings:

1. High load - bearing capacity: Utilizing two rows of steel balls of different diameters, this design not only enhances load capacity but also improves overall stability. The bearing angle of the upper and lower arc raceways is 90°, allowing it to effectively withstand significant axial forces and overturning moments, making it suitable for heavy-duty applications.

2. High Precision and Stability : The double-row ball design provides better shock and vibration absorption. As the steel balls roll on the raceways, they effectively cushion external impacts and reduce vibration transmission, thereby enhancing overall stability.

3. Strong Adaptability : QIBR employs high-quality materials and precision manufacturing processes to ensure reliability and durability in harsh environments. The high standards of manufacturing allow the bearings to operate normally in high-temperature, high-humidity, and corrosive conditions.

Additional Notes:

The Canadian customer decided to procure QIBR's double-row ball slewing bearings to meet the safety and reliability requirements of high-capacity tower cranes. The design of QIBR's double-row ball slewing bearings is optimized for heavy loads, effectively distributing the load and meeting the high-load demands of tower cranes when lifting heavy objects. The high load capacity ensures the safety and stability of the crane during operation, making it an ideal choice for high-capacity tower cranes and fulfilling the customer’s needs for efficiency, reliability, and profitability.