QIBR delivered precision angular contact ball bearings and deep groove ball bearings to a customer in France for use in the spindles of precision CNC machine tools, enhancing high precision and stability

- Continent

- Europe

- Country

- France

- Date

- 2016-01-22

- Applications

- Precision CNC machine tool spindles

Products Used

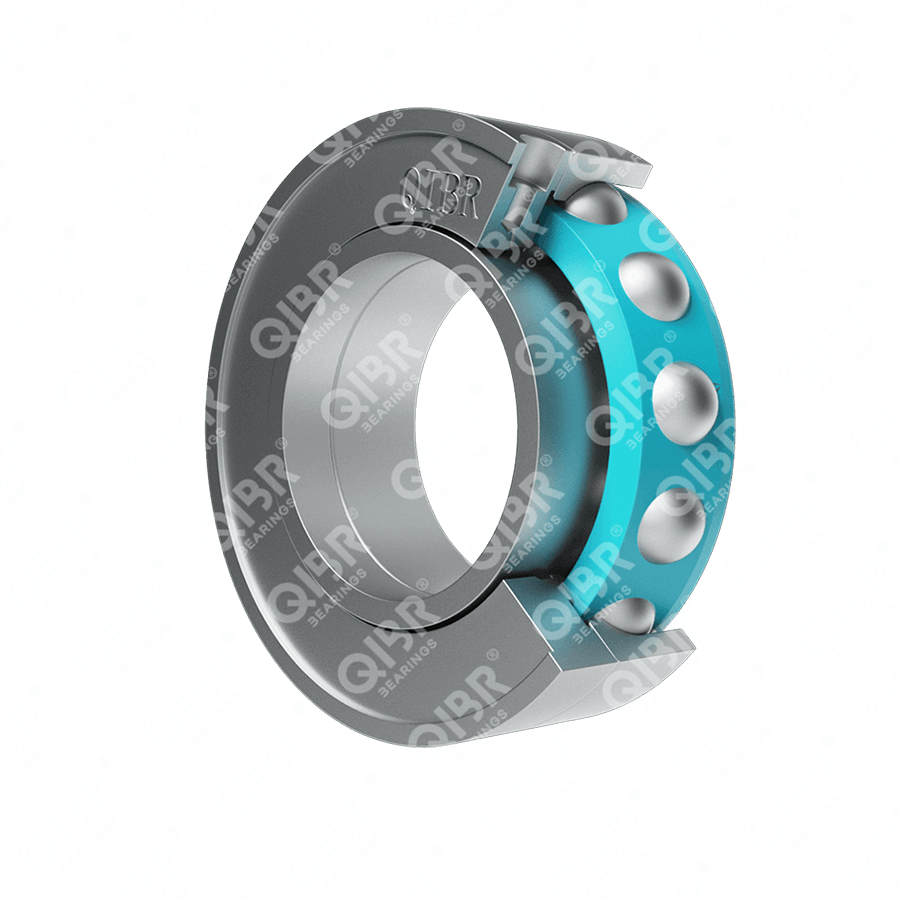

Angular Contact Ball Bearings

1. High load - bearing capacity: The presence of the contact angle allows the load to be transmitted through the contact points between the balls and the inner and outer rings, enhancing load capacity. Angular contact ball bearings can simultaneously handle significant radial and axial loads.

2. Structural Design : The design features a large number of oversized balls, and the chamfer design has been optimized by QIBR's technical department to meet ISO 02 standards. The outer ring has an asymmetric design, with a high-temperature PEEK cage and high-speed grease injection.

3. Low Friction and High-Speed Performance : The low coefficient of friction makes angular contact ball bearings suitable for high-speed applications, supporting stable operation of the spindle at high speeds and reducing heat generation.

Deep Groove Ball Bearings

1. High load - bearing capacity: Capable of withstanding significant radial loads and, to a certain extent, axial loads, making it suitable for spindle applications that require stability.

2. Structural Design : he cage is made from high-temperature glass fiber reinforced composite polymer, with dimensions conforming to ISO 15:1998 standards. The dimensional tolerance is P6, the rotational accuracy is P6, and the radial internal clearance is C3, with an allowable angular error between 2 to 10 arcminutes.

3. Low Noise and Low Vibration :Deep groove ball bearings generate minimal noise and vibration during operation, contributing to an improved working environment and processing accuracy for machine tools.

Additional Notes:

The French customer decided to procure QIBR's precision angular contact ball bearings and deep groove ball bearings as equivalent replacements for NSK bearings to meet the high precision and stability demands of their precision CNC machine tool spindles. QIBR bearings utilize high-quality materials and precision machining processes, featuring a low coefficient of friction suitable for high-speed operation. This advantage allows the machine tool to maintain high efficiency at high speeds, reducing energy consumption and heat generation. With strict quality control, they also exhibit excellent wear resistance and fatigue performance. This reliability not only extends the service life of the bearings but also reduces maintenance costs, enhancing the overall return on investment for the customer.