QIBR four-point contact ball bearings were delivered to customers in Guangzhou, China, to improve the stability and accuracy of CNC milling machine spindles

- Continent

- Asia

- Country

- China

- Date

- 2016-10-09

- Categories

-

Four-Point Contact Ball Bearing

- Applications

- CNC Milling Machine Spindle

Products Used

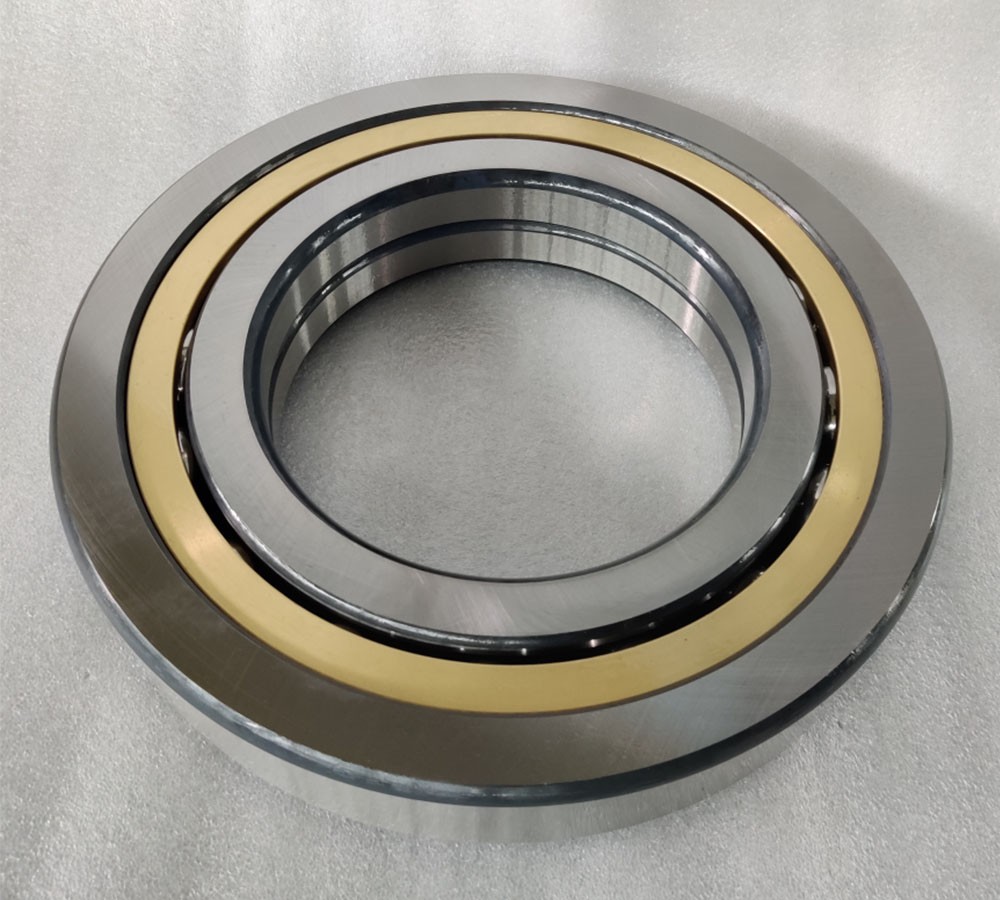

Four-point Contact Ball Bearings

1. High load capacity: QJ315 four-point contact ball bearings evenly distribute the load on the four contact points of the inner and outer rings, and can simultaneously withstand bidirectional axial loads and radial loads. It has a very high axial load capacity and is suitable for CNC milling machine spindles that need to withstand large loads.

2. Structural Optimization: The raceway of the QJ315 four-point contact ball bearing is designed with high shoulders and large contact angles to improve the load capacity and enhance stability under high loads. It is more efficient in space utilization and can provide greater load support in a smaller installation space.

3. High precision: The QJ315 four-point contact ball bearing has a large number of rolling elements. Each ball disperses the load at multiple contact points, reducing vibration and noise during operation and improving the processing accuracy and stability of the CNC milling machine.

Additional Notes:

Chinese customers choose to purchase QIBR's QJ315 four-point contact ball bearings to improve the stability and accuracy of the CNC milling machine spindle. QIBR uses advanced bearing manufacturing technology to ensure that the accuracy of the QJ315 four-point contact ball bearings is at an extremely high level. The fit between the inner and outer rings and the rolling elements is very precise, reducing the error during operation and improving the positioning accuracy of the CNC milling machine spindle. The QJ315 four-point contact ball bearing uses high-quality lubricating materials and precise process design to reduce the friction coefficient, extend the service life of the bearing, reduce heat generation during operation, and reduce the noise during spindle operation. Improve the operating stability of the CNC milling machine and ensure long-term high-precision processing.