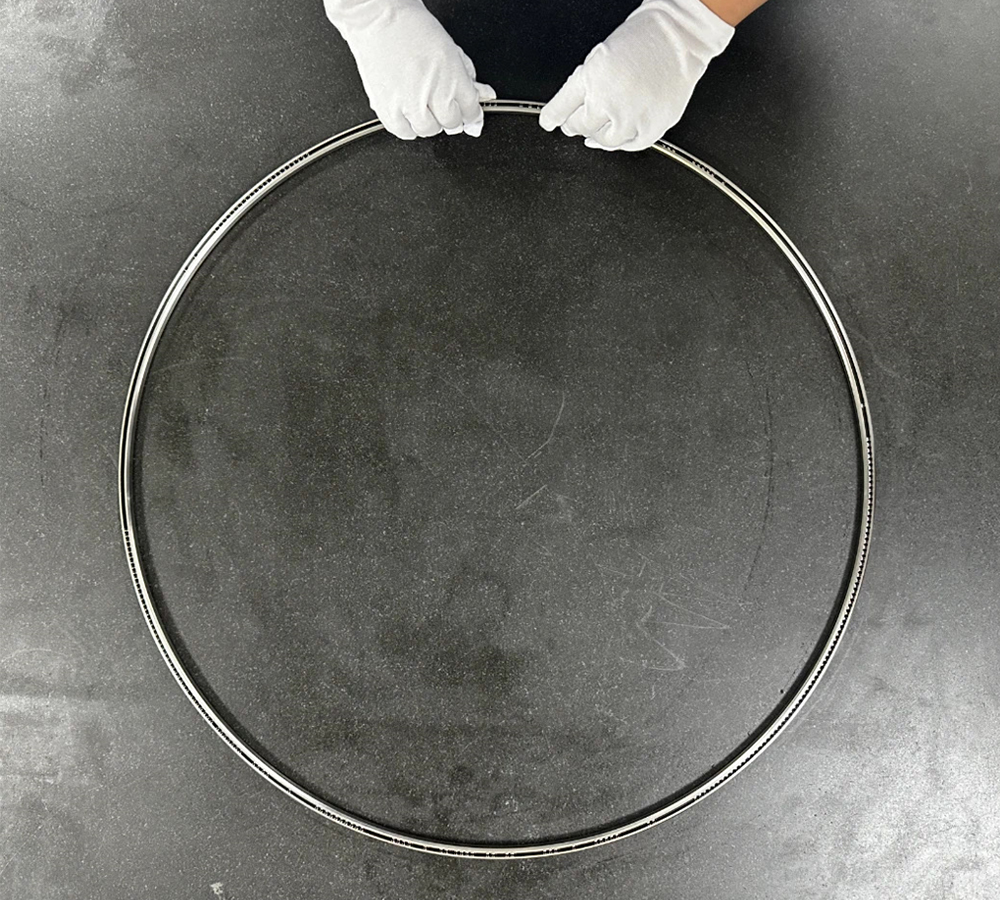

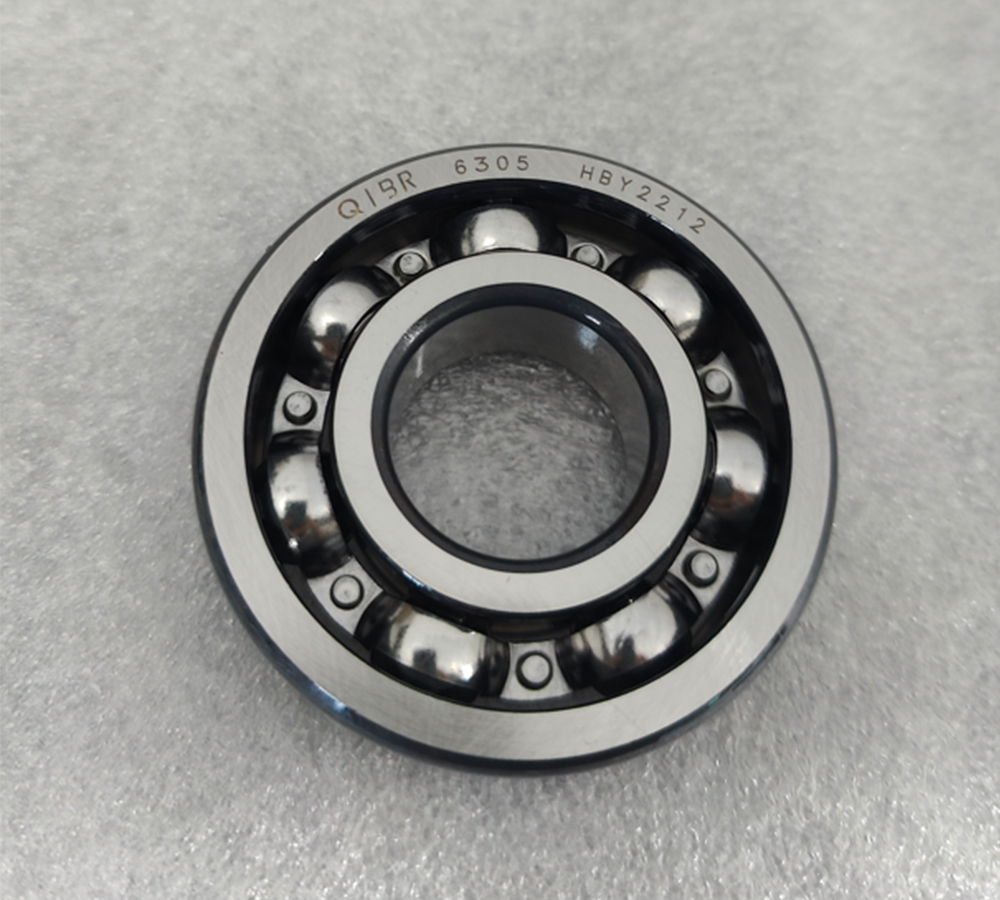

QIBR high-precision thin-section ball bearings and stainless steel deep groove ball bearings delivered to a customer in Vancouver, Canada, for ensuring accuracy and reliability in optical scanners

- Continent

- North America

- Country

- Canada

- Date

- 2016-02-27

- Applications

- Industrial Robots,Heavy-Duty Robotic Arms

Products Used

High-Precision Thin-Section Ball Bearings and Stainless Steel Deep Groove Ball Bearings

1. High Precision and Stability: QKA120AR0 High-Precision Thin-Section Ball Bearings: The thin-section structure reduces overall weight while providing higher rotational speeds and lower inertia in limited space. This design minimizes vibrations and errors during high-speed rotation, improving the clarity and accuracy of scanned images. 6305 Stainless Steel Deep Groove Ball Bearings: The precisely machined raceways of the inner and outer rings result in lower friction during operation, enhancing efficiency and reducing energy loss. These bearings are suitable for high-speed applications and support the weight of moving components in the optical scanner.

2. Corrosion Resistance: 6305 Stainless Steel Deep Groove Ball Bearings: Stainless steel provides excellent resistance to moisture, chemicals, and other corrosive environments, making it highly durable even in harsh conditions. This ensures the bearings retain their structural integrity and functionality, even in corrosive or humid settings.

3. Low Noise Operation: Both the high-precision thin-section ball bearings and the 6305 stainless steel deep groove ball bearings undergo precision machining, ensuring smooth rolling contact. Superior surface finish and optimized geometry effectively reduce friction and lower operational noise.

Additional Notes:

The Canadian customer decided to purchase QIBR’s QKA120AR0 high-precision thin-section ball bearings and 6305 stainless steel deep groove ball bearings to meet the requirements of their optical scanner for precision and reliability. QIBR uses advanced technology in the design and manufacture of these bearings, ensuring that each one meets the highest precision standards. This level of precision allows the optical scanner to capture and process images with greater accuracy, meeting the stringent demands of professional applications.