QIBR high-speed cylindrical roller bearings and precision deep groove ball bearings delivered to British customers, with high stability and reliability for aerospace turbochargers

- Continent

- Europe

- Country

- United Kingdom

- Date

- 2016-01-26

- Categories

-

Deep Groove Ball Bearing

Tapered Roller Bearing

- Applications

- Aerospace Turbocharger

Products Used

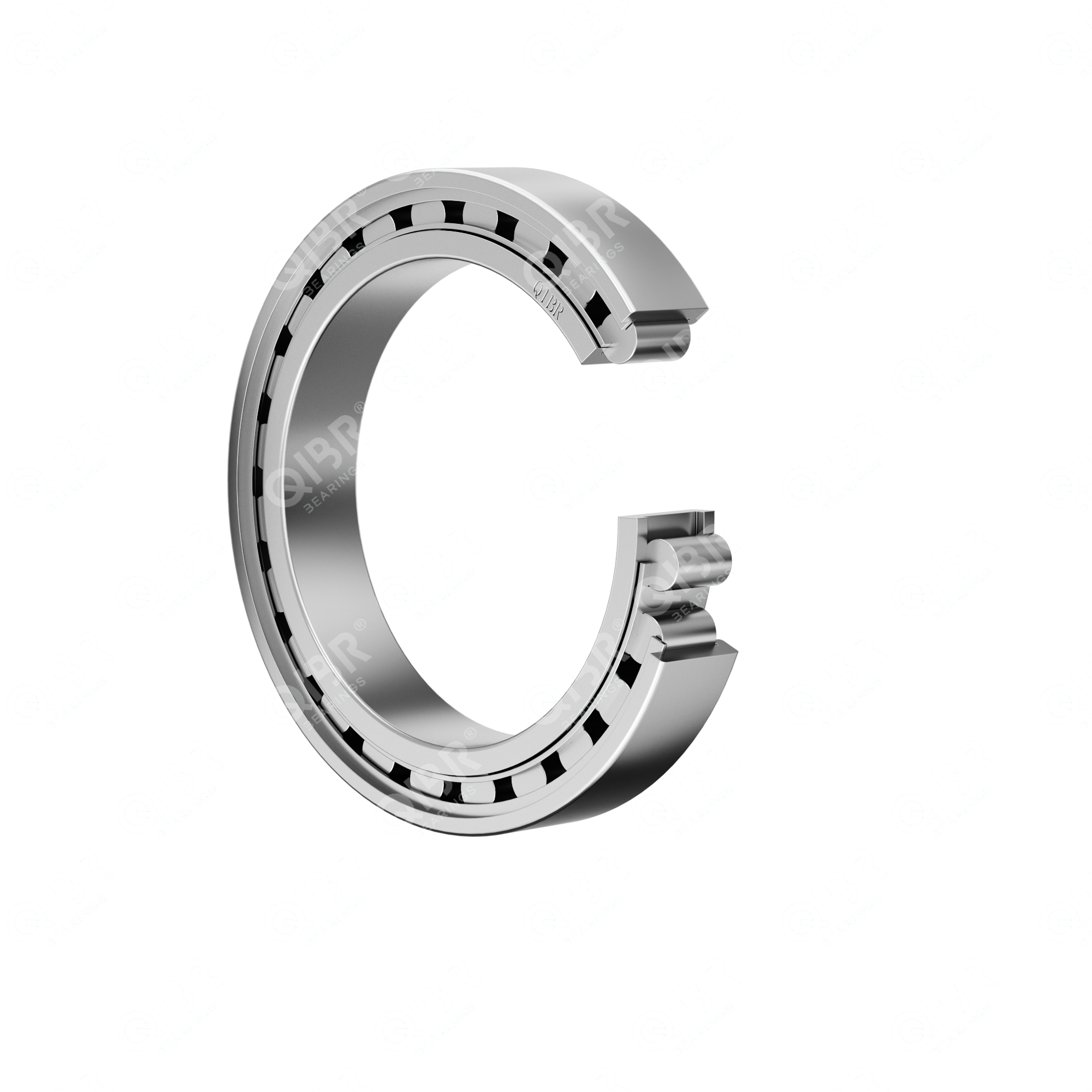

High speed cylindrical roller bearings & Precision deep groove ball bearings

1. High-speed performance: QIBR uses high-quality steel and special heat treatment process to manufacture bearings. High-quality materials have high hardness, high strength and excellent fatigue resistance. The structure is optimized and designed with reasonable cross-sectional shape and size to improve the overall rigidity and stability. It can withstand large centrifugal force and heat at high speed and maintain stable performance during high-speed operation.

2. High load capacity: QIBR bearings are designed with high load requirements required by turbochargers in mind. Cylindrical roller bearings can withstand large radial loads, while precision deep groove ball bearings provide good radial support. The combination of the two bearings ensures the reliability of the turbocharger under various working conditions.

3. Low friction and noise: QIBR bearings are designed with attention to friction and noise control. Its low friction characteristics not only improve energy efficiency, but also reduce heat generation, ensuring the smooth operation of the turbocharger. At the same time, the low noise characteristics of QIBR bearings also meet the strict requirements of noise control in the aerospace field.

Additional Notes:

British customers decided to purchase QIBR's high-speed cylindrical roller bearings and precision deep groove ball bearings to meet the safety, high stability and reliability requirements of aerospace turbochargers. QIBR implements strict quality control during the production process to ensure that each bearing meets high standards of reliability. This is crucial for key equipment in the aerospace field, and can provide users with long-lasting performance guarantees, ensuring the efficient and smooth operation of turbochargers in harsh environments, and providing reliable protection for equipment in the aerospace field.