QIBR linear roller bearings are delivered to customers in Poznan, Poland, and are used in the paper conveying system of printing presses to improve precision and stability

- Continent

- Europe

- Country

- Poland

- Date

- 2016-04-21

- Categories

-

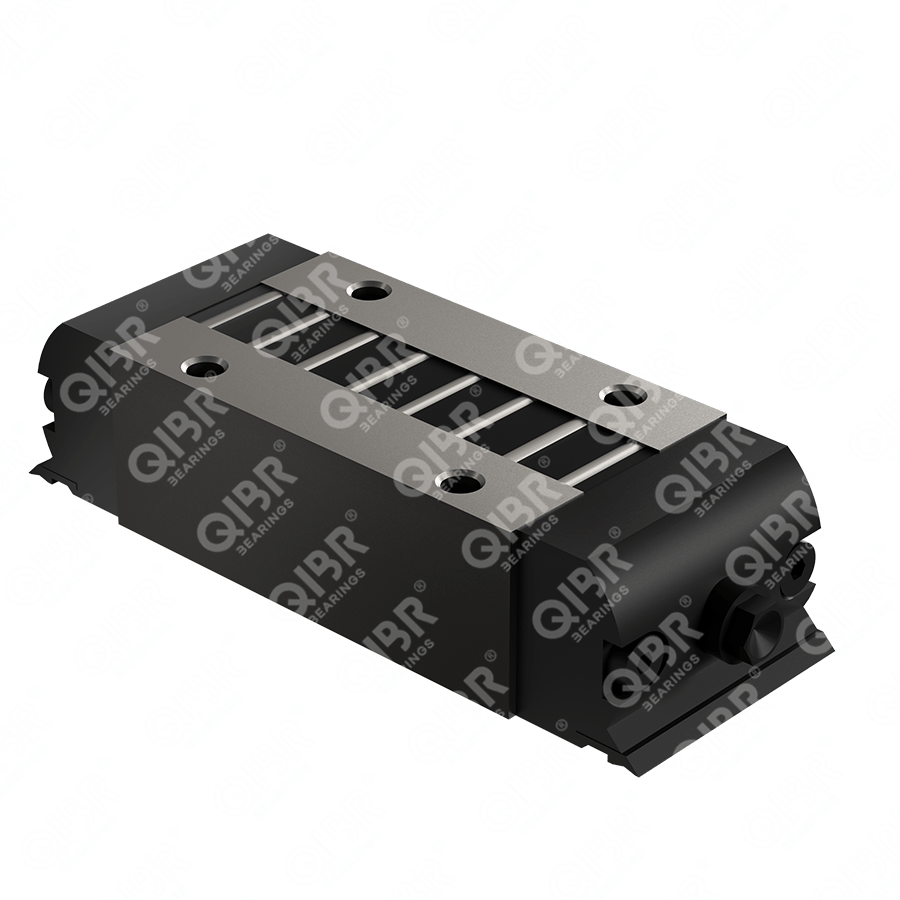

Linear Roller Bearings

- Applications

- Paper conveying system of printing press

Products Used

Linear roller bearings

1. High Load Capacity: The RUS26126ks linear roller bearing can bear large radial and axial loads. The design of multiple rows of rollers increases the contact area between the rollers and the inner and outer rings. This enables the bearing to effectively distribute the load and improve the load-carrying capacity. It is suitable for the high load conditions required in the paper conveying process.

2. Low friction and high efficiency: The RUS26126ks linear roller bearing has a low friction coefficient. It is made of high-performance materials and has good wear resistance and impact resistance. This enables the bearing to maintain performance even in a high-load environment. It has lower energy consumption during operation and is suitable for the demand of modern printing presses for fast paper conveying and improves production efficiency.

3. Precise positioning and stability: The RUS26126ks linear roller bearing provides excellent positioning accuracy and can remain stable during operation without easy vibration and offset. It ensures the accuracy of paper during the conveying process and reduces printing errors caused by position deviations.

Additional Notes:

The Polish customer decided to purchase the RUS26126ks linear roller bearing of QIBR Company to meet the requirements of precision and stability of its printing press paper conveying system. The RUS26126ks linear roller bearing has a relatively high load capacity and can still maintain good performance under high-speed and heavy-load conditions, meeting the needs of printing presses in various working states. QIBR's bearings have good wear resistance and corrosion resistance and can work stably for a long time in harsh environments. After fine processing, it can provide excellent positioning accuracy. Ensure the accurate position of paper during the conveying process, thereby improving the printing accuracy and quality and reducing material waste caused by errors. It is crucial for the paper conveying system of printing presses.