QIBR Linear Roller Bearings Delivered to a Customer in Milan, Italy, for Use in Assembly Line Robotic Arms to Improve Precision Control and Stability

- Continent

- Europe

- Country

- Italy

- Date

- 2016-05-08

- Categories

-

Linear Roller Bearings

- Applications

- Assembly Line Robotic Arms

Products Used

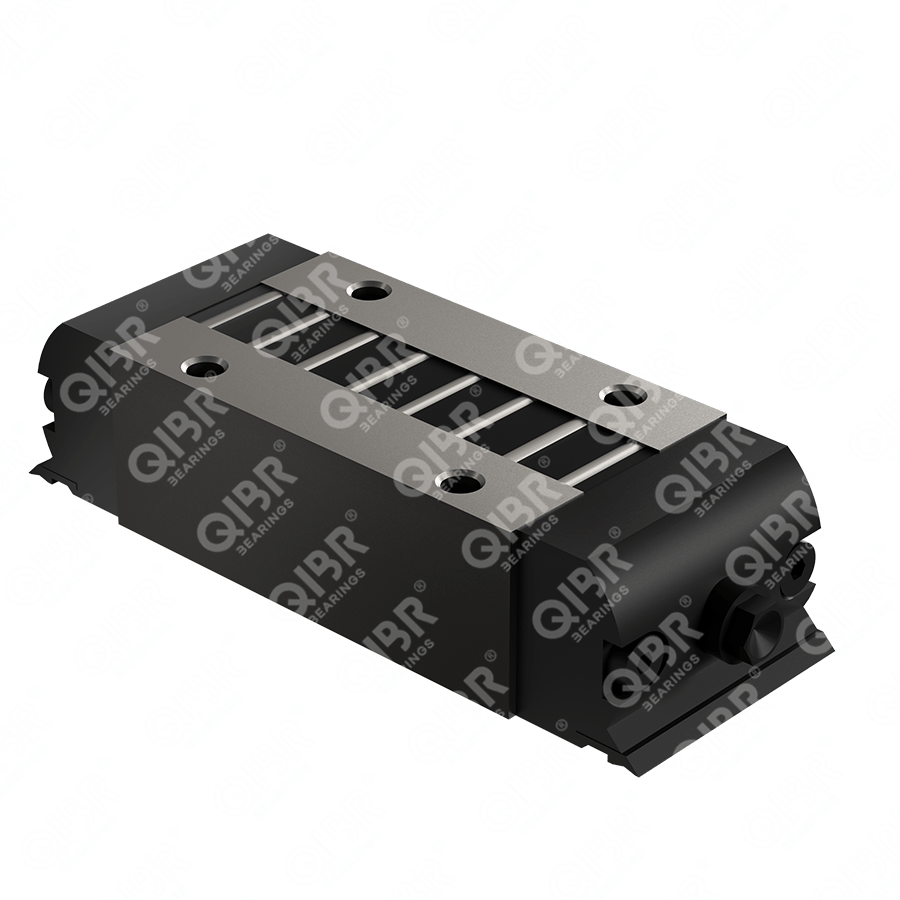

Linear Roller Bearings

1. High Load Capacity: The RUS 38134-KS linear roller bearings are designed to handle significant radial and axial loads. The large contact area between the inner and outer rings allows the rollers to distribute the load evenly, reducing stress concentrations and increasing the overall load-bearing capacity. This ensures safety and stability during operation.

2. Precision and Accuracy: The dimensional tolerances of the components in the RUS 38134-KS linear roller bearings are kept within minimal ranges to ensure precise fitting. The finely machined guide rails and raceways ensure the rollers move with stability, reducing deviations and improving positioning accuracy, which is essential for tasks that require high-precision positioning in assembly operations.

3. Low Friction and Smooth Operation: The RUS 38134-KS linear roller bearings enable low-friction smooth motion, improving energy efficiency and reducing component wear. For robotic arms that undergo frequent motion, the low friction characteristic significantly reduces energy consumption and enhances reliability.

Additional Notes:

The Italian customer recently decided to purchase RUS 38134-KS linear roller bearings from QIBR to meet the demands for improved precision and stability in their assembly line robotic arms. The RUS 38134-KS bearings are manufactured using advanced processes to ensure high-precision operation during movement. Through rigorous quality control and testing, these bearings enhance high-precision performance under both dynamic and static loads, ensuring accurate movements of the robotic arms and boosting the overall efficiency of the assembly line. The RUS 38134-KS bearings are made from high-quality materials and utilize innovative lubrication technology, offering excellent wear resistance and corrosion protection. Even under high load conditions, they maintain their accuracy, supporting more complex and high-intensity operational demands to meet the stringent performance requirements of modern industrial equipment.