QIBR Plain Bearings and Deep Groove Ball Bearings Delivered to Monterrey, Mexico Customer for Harvester Vibrating Screen Stability and Load Capacity

- Continent

- Sourth America

- Country

- Mexico

- Date

- 2016-04-08

- Categories

-

Deep Groove Ball Bearing

Joint Bearing

- Applications

- Harvester Vibrating Screen

Products Used

Deep Groove Ball Bearing

1. High Load Capacity: The 6312 deep groove ball bearing can handle both radial and axial loads, making it suitable for applications like vibrating screens where multidirectional vibrations occur, thus improving equipment stability.

2. High-Speed Operation Capability: The bearing's contact area between the rolling elements and the inner and outer rings is small, which reduces friction and heat generation during high-speed operation. This allows for smooth operation in the harvester's vibrating screen, minimizing vibration impact on the equipment and improving overall work efficiency.

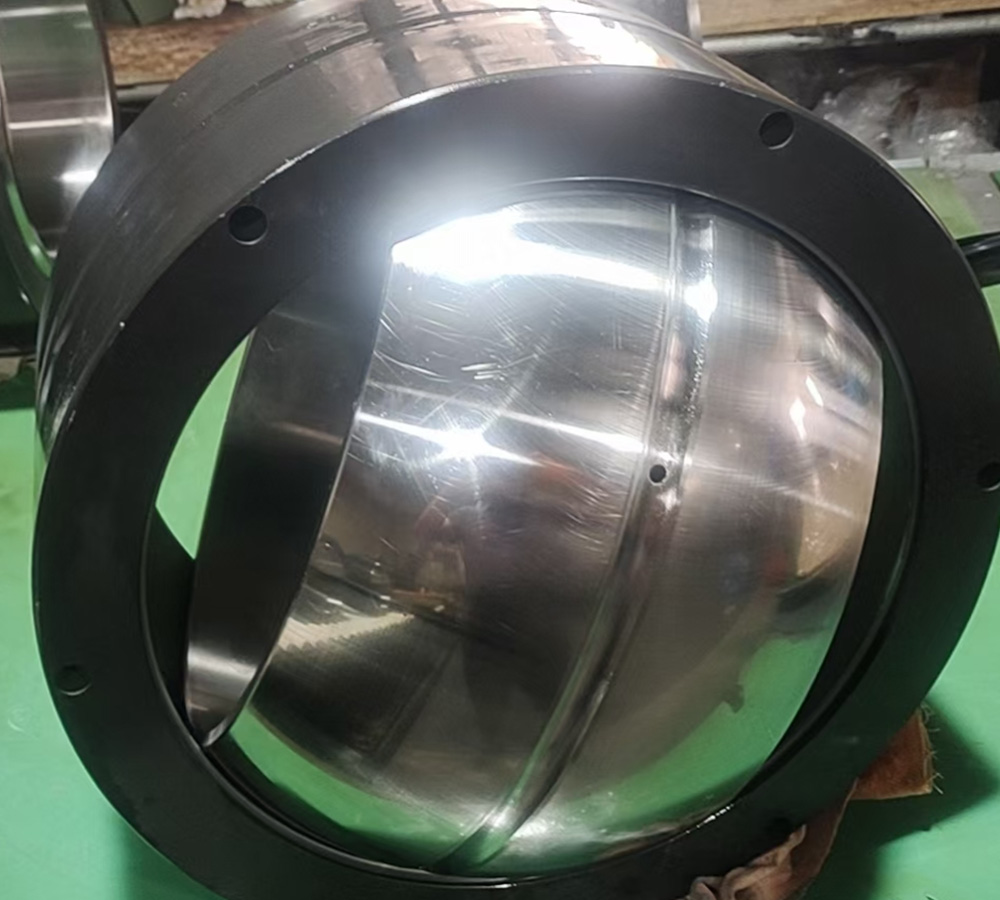

Plain Bearing

1. High Load Capacity: With a large contact area, the GE82ZO plain bearing effectively distributes the load, reducing pressure per unit area and enabling it to support heavy loads. Made from high-performance materials, the bearing enhances durability and load capacity, making it ideal for heavy load and high-vibration working environments.

2. Low Friction and Heat Generation: The bearing has a relatively low coefficient of friction, which reduces heat generated by friction. This helps maintain the stability of the vibrating screen, reduces failure rates, and extends the service life of the equipment.

Additional Notes:

The Mexican customer decided to procure QIBR’s GE82ZO plain bearings and 6312 deep groove ball bearings to meet the stability and load capacity demands of their harvester's vibrating screen. Both bearings, made with premium materials and advanced manufacturing processes, ensure durability and reliability in high-load and high-speed working environments. QIBR’s GE82ZO plain bearings and 6312 deep groove ball bearings exhibit excellent performance by reducing wear and extending service life. Their precision design and large load capacity meet the heavy-load requirements of the vibrating screen in harvesters.