QIBR precision angular contact ball bearings, high-speed tapered roller bearings and high-precision cross roller bearings were delivered to German customers for the spindle drive of precision CNC machine tools

- Continent

- Europe

- Country

- Germany

- Date

- 2016-01-04

- Applications

- spindle transmission,Precision CNC machine equipment

Products Used

Precision Angular Contact Ball Bearings

With a low friction coefficient, these bearings maintain stability at high speeds, making them ideal for the high-speed requirements of modern CNC machine tools. QIBR precision angular contact ball bearings are manufactured with high precision, providing excellent rotational accuracy, which directly impacts the machining accuracy and surface quality of machine tools.

High-Speed Tapered Roller Bearings

These bearings can handle significant radial and single-direction axial loads while maintaining stability at high speeds. With a larger contact angle, high-speed tapered roller bearings offer enhanced axial load-carrying capacity.

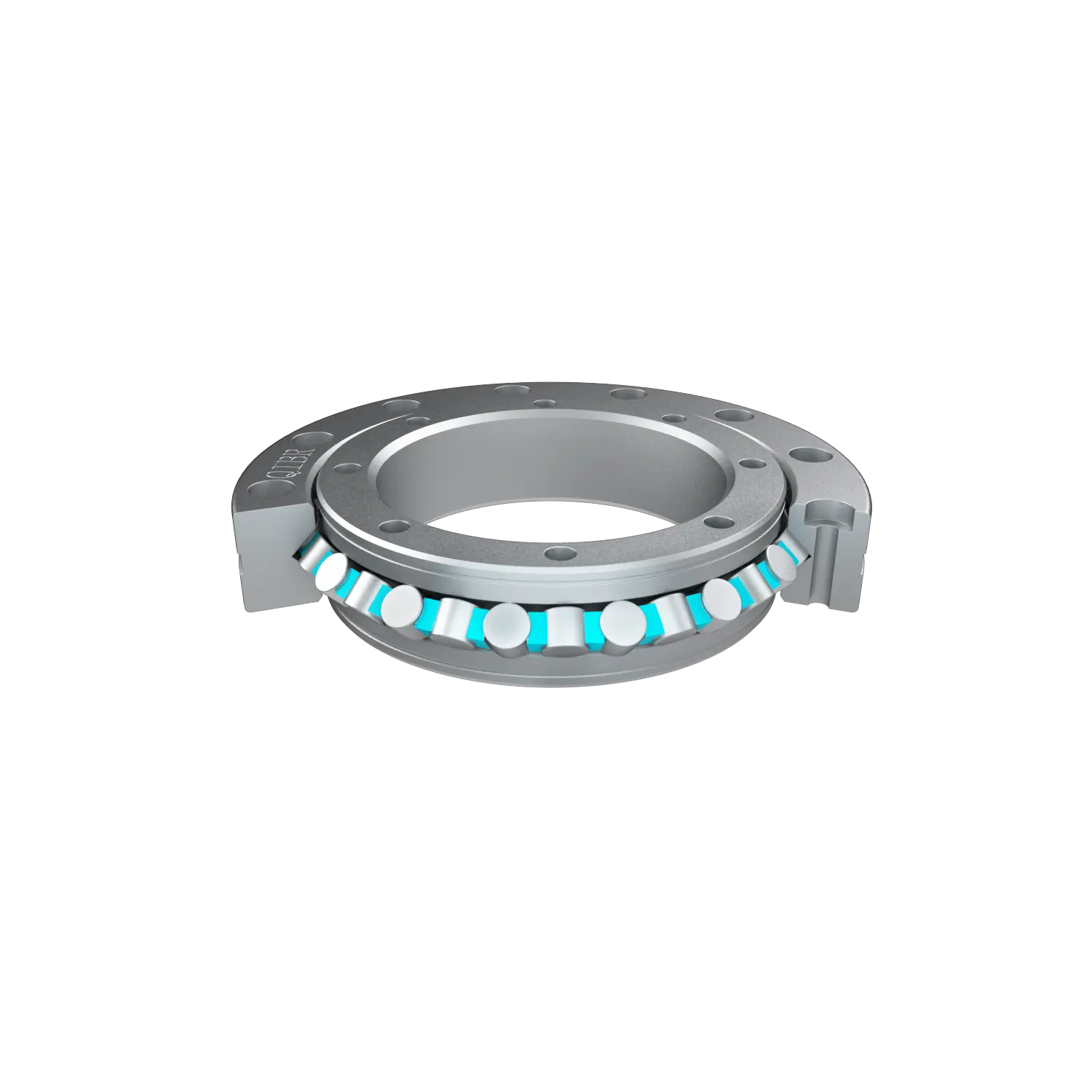

High-Precision Crossed Roller Bearings

Crossed roller bearings can simultaneously handle radial forces, bidirectional axial forces, and overturning moments, making them suitable for complex operating conditions. Their compact structure makes them ideal for space-constrained machine designs, improving overall machine stability and machining precision. The design of crossed roller bearings excels in high-precision applications, meeting the stringent accuracy demands of modern CNC machine tools.

Additional Notes:

The German customer ultimately chose QIBR's precision angular contact ball bearings, high-speed tapered roller bearings, and high-precision crossed roller bearings as replacements for FAG bearings. QIBR bearings are produced using advanced manufacturing techniques and stringent quality control, offering exceptional rotational accuracy and stability to meet the demanding requirements of CNC machine tool spindle drive systems. The optimized contact angles and internal clearance significantly enhance radial and axial load-bearing capacity, enabling spindle drive systems to withstand higher machining forces, thereby improving machining efficiency. With premium materials, heat treatment processes, and precise manufacturing technology, QIBR bearings provide extended service life, reducing maintenance costs and increasing machine reliability.