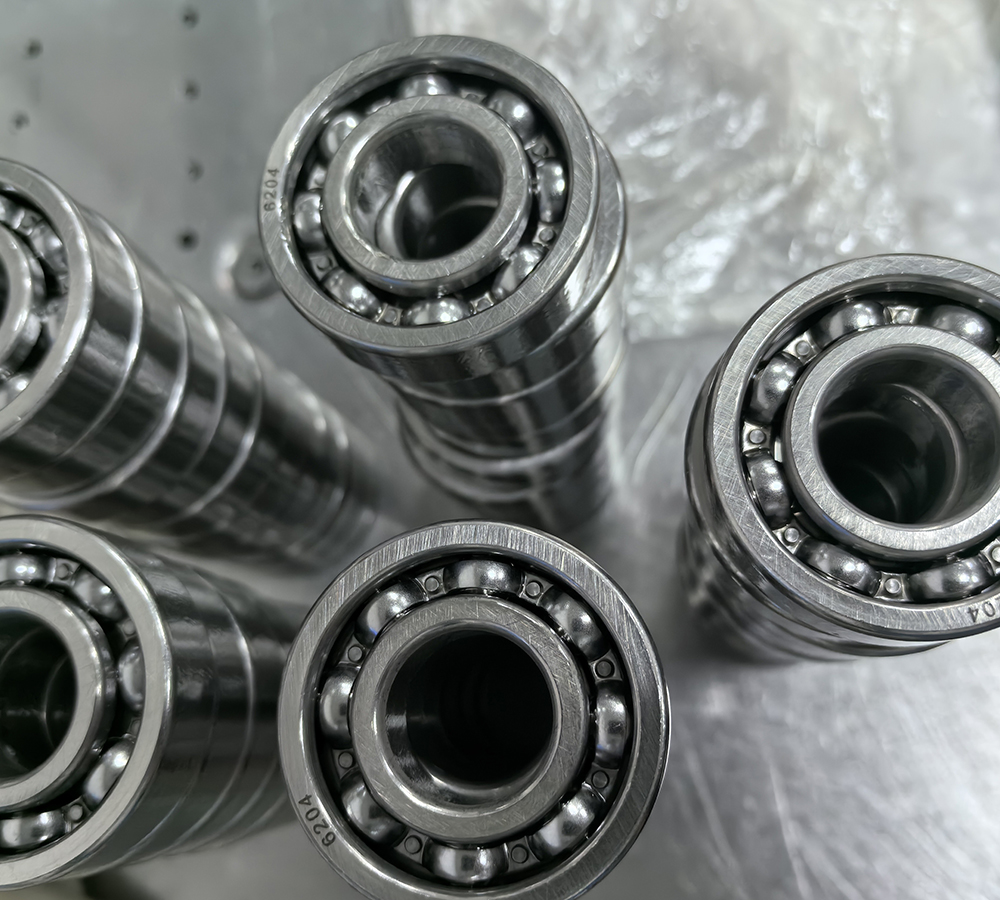

QIBR precision deep groove ball bearings delivered to customers in Glasgow, UK, to improve stability and efficiency with precision CNC machine tool tool rotation

- Continent

- Europe

- Country

- United Kingdom

- Date

- 2016-02-01

- Categories

-

Deep Groove Ball Bearing

- Applications

- Precision CNC machine tools,tool rotation

Products Used

Deep groove ball bearings

1. High precision: 6204 precision deep groove ball bearings use advanced processing technology to ensure that the size and shape accuracy of each component reaches strict standards. Through high-precision turning, grinding and polishing processes. The surface finish of the inner and outer rings and rolling elements of the bearing is significantly improved, reducing friction and wear during operation, reducing processing errors, and improving the processing accuracy of the workpiece.

2. Low friction performance: 6204 precision deep groove ball bearings use high-strength, wear-resistant materials, with low friction coefficient and good wear resistance. The use of high-quality materials ensures the stability and low friction performance of the bearings in long-term operation. It not only improves the rotation efficiency of the tool, but also reduces the heat generation and extends the service life of the bearing and tool.

3. Strong carrying capacity: QIBR 6204 precision deep groove ball bearings can withstand large radial and axial loads and are suitable for use under high load conditions. The tool can work stably during the cutting process, reducing vibration and deformation, thereby improving the processing quality.

Additional Notes:

The British customer decided to purchase QIBR 6204 precision deep groove ball bearings as an equivalent replacement for INA bearings, aiming to meet the needs for stability and high efficiency in the rotation of CNC machine tool tools. The application of QIBR 6204 precision deep groove ball bearings in CNC machine tool tool rotation ensures customers' demand for stability and high efficiency with its advantages of high precision, low friction performance, strong load-bearing capacity, high-quality materials and strong adaptability. need. QIBR is able to provide more competitive prices through large-scale production and lean management. Compared with brands such as INA, customers can reduce procurement costs while ensuring performance, thereby increasing overall profit margins.