QIBR self-aligning ball bearings and deep groove ball bearings are delivered to customers in Utrecht, the Netherlands to ensure reliability and high temperature resistance for metallurgical cooling machines

- Continent

- Europe

- Country

- Netherlands

- Date

- 2016-04-01

- Applications

- Metallurgy,cooling machine

Products Used

Deep Groove Ball Bearings

1. High load - bearing capacity: The inner and outer ring raceways of the 618/6 deep groove ball bearing are designed with a relatively deep depth, and the balls can better disperse and support the load when rolling. The deep groove design increases the contact area and improves the bearing capacity for radial and axial loads.

2. Adapt to high-speed operation: It has a low friction coefficient and can remain stable during high-speed operation, helping to improve the stability of the mechanical system and reduce noise. It can effectively reduce energy loss and is crucial for the efficient operation of metallurgical cooling machines.

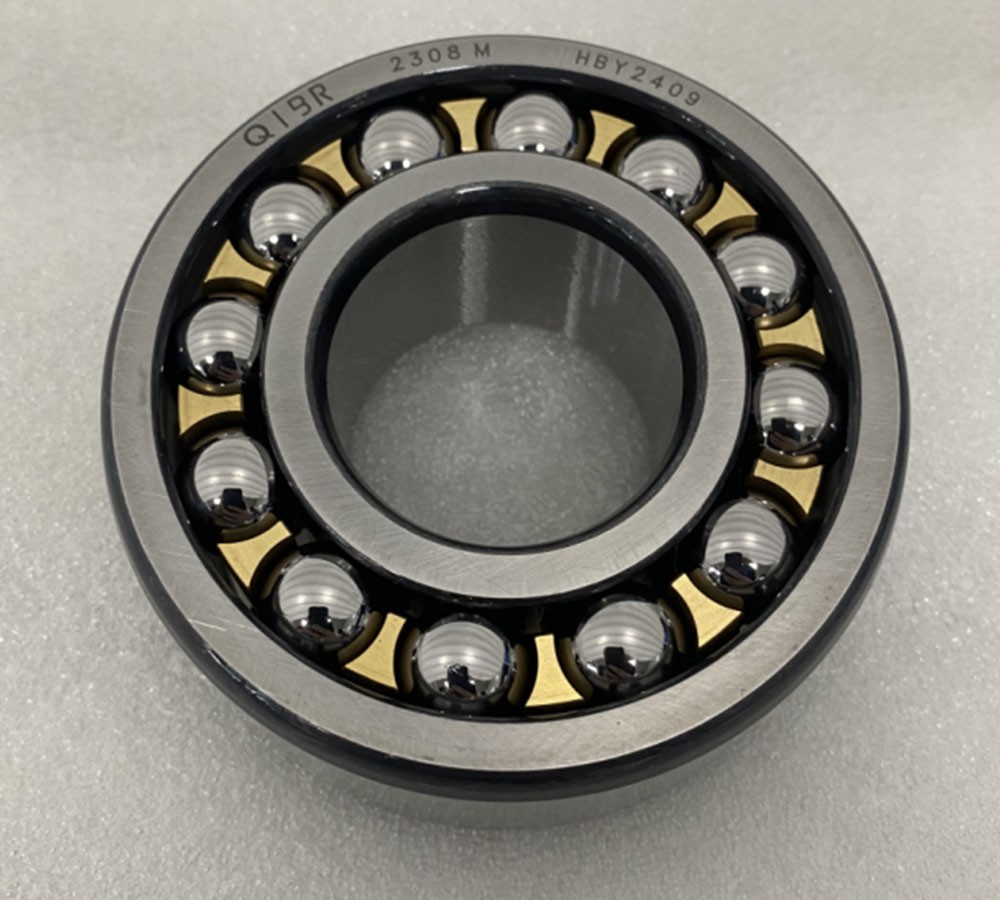

Self-aligning ball bearing

1. Self-aligning Capability: The 2308 self-aligning ball bearing can automatically adjust the relative positions of the inner and outer rings to adapt to the shaft misalignment caused by inaccurate installation or equipment deformation, reducing the failure of the cooling machine due to deformation under high temperature and high load.

2. Strong load-carrying capacity: Increasing the contact area between the rolling elements and the raceway can simultaneously bear larger radial and axial loads, helping to evenly distribute the load and improve the stability and load-carrying capacity of the bearing. Using high wear-resistant materials can maintain good performance in harsh environments.

Additional Notes:

After evaluation, Dutch customers finally decided to purchase the 2308 self-aligning ball bearings and 618/6 deep groove ball bearings of QIBR company to meet the strict requirements of metallurgical cooling machines in terms of reliability and high temperature resistance. QIBR company has advanced production technology and a strict quality control system in bearing manufacturing. High temperatures are often accompanied in metallurgical processes. Selecting bearings with high temperature resistance helps reduce the risk of material fatigue and damage caused by high temperatures. Both the 2308 self-aligning ball bearing and the 618/6 deep groove ball bearing are made of high-performance materials and have excellent high temperature resistance and corrosion resistance, and can operate stably for a long time in extreme environments. The design of the 2308 self-aligning ball bearing enables it to automatically adjust during installation and use to adapt to the deviation of the bearing seat, improving the overall operating efficiency and production stability of the equipment.