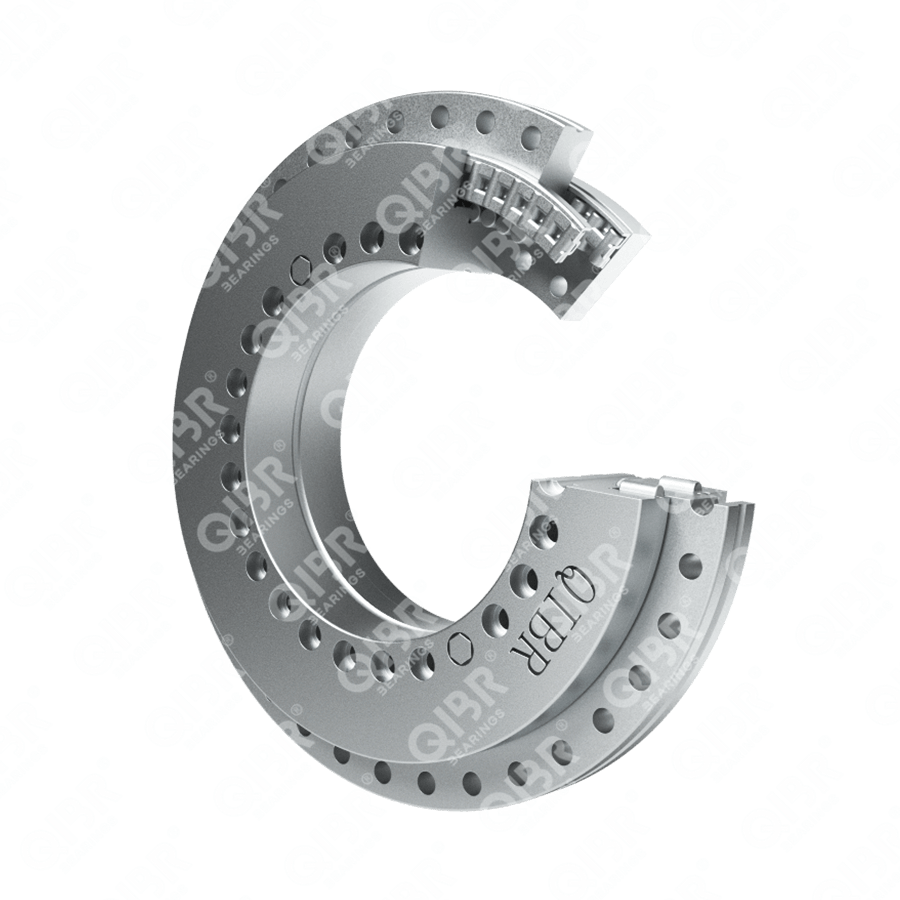

QIBR slewing bearings are delivered to customers in Bogotá, Colombia to improve the stability and durability of the upper slewing of excavators

- Continent

- Sourth America

- Country

- Columbia

- Date

- 2016-05-11

- Categories

-

Slewing Bearing

- Applications

- upper slewing of excavator

Products Used

slewing bearing

1. Strong load-carrying capacity: The YRTS460 slewing bearing has a large contact area and can distribute the load. Distribute the force evenly and reduce local stress. It can bear various loads such as axial, radial and overturning moments at the same time, improving the load-carrying capacity. Maintain good performance in various working environments and adapt to different load combinations to improve the overall load-carrying capacity.

2. Low friction: The YRTS460 slewing bearing is precisely processed, and the surface finish and dimensional accuracy are greatly improved, reducing friction caused by rough surfaces. The grease forms a protective film inside the bearing, reducing direct contact between metal surfaces. Reduce friction and ensure smooth operation.

3. Durability and reliability: The YRTS460 slewing bearing is made of wear-resistant materials and has excellent fatigue resistance and corrosion resistance. It can maintain stable performance in harsh environments. After surface hardening treatment, the wear resistance and corrosion resistance are improved and the service life is prolonged.

Additional Notes:

Colombian customers purchase YRTS460 slewing bearings from QIBR company to meet the requirements for stability and durability of the upper slewing part of their excavators. QIBR company has rich experience in the design and manufacture of YRTS460 slewing bearings. It uses high-quality materials and advanced production processes to ensure reliability and durability under high loads and harsh working conditions. After strict testing and quality control, the failure rate can be effectively reduced. QIBR's YRTS460 slewing bearing has excellent load-carrying capacity and supports the upper slewing mechanism of the excavator. During operation, the excavator can maintain stability, reduce vibration and tilting caused by imbalance, and improve operation safety and efficiency. The design of the YRTS460 slewing bearing allows the excavator to rotate flexibly 360 degrees during work and effectively complete various complex operation tasks and improve construction efficiency.