QIBR slewing bearings delivered to customers in Cologne, Germany, to improve safety and stability of large ship cranes

- Continent

- Europe

- Country

- Germany

- Date

- 2016-02-22

- Categories

-

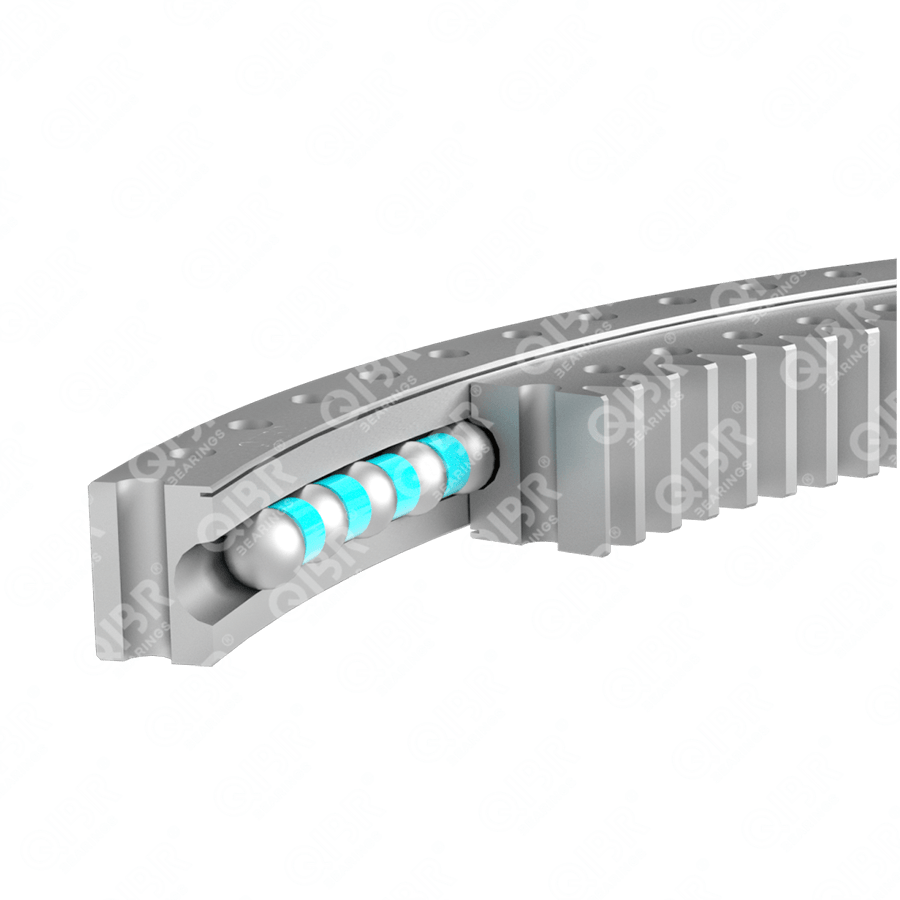

Slewing Bearing

- Applications

- large ship marine cranes

Products Used

Slewing Bearing:

1. Strong load-bearing capacity : 013.50.4500 slewing bearing can withstand axial force, radial force and overturning moment at the same time, and its large size can disperse the applied load. The processing accuracy and surface quality of the materials are strictly controlled during the manufacturing process to ensure the matching accuracy of each component, improve the overall load-bearing capacity and service life, and are suitable for the high load requirements of marine cranes under complex working conditions.

2. Low friction and high efficiency : The 013.50.4500 slewing support bearing uses balls as rolling elements. When the rolling elements roll between the inner and outer rings, the friction is small. The geometry is optimized to maintain good centering during rotation, reducing unnecessary lateral forces and friction. The crane is more flexible during operation and improves work efficiency.

3. Compact structure : The 013.50.4500 slewing support bearing uses high-strength steel and advanced manufacturing technology. The bearing can still maintain a small volume when subjected to high loads. The design is relatively compact, effectively saving space, making the overall structure of the marine crane more concise.

Additional Notes:

The German customer decided to purchase 013.50.4500 slewing support bearing from QIBR as an equivalent replacement for NACHI bearings, aiming to meet the high requirements for safety and stability of large ship marine cranes. QIBR 013.50.4500 slewing support bearing design can withstand large radial and axial loads at the same time, suitable for heavy-duty operations of large ships. Ensure the safety and stability of marine cranes under extreme working conditions.