QIBR slewing rings delivered to customers in New York, USA, used in wind turbines to improve stability

- Continent

- North America

- Country

- The United States

- Date

- 2016-01-31

- Categories

-

Slewing Bearing

- Applications

- wind turbine

Products Used

Slewing Bearing:

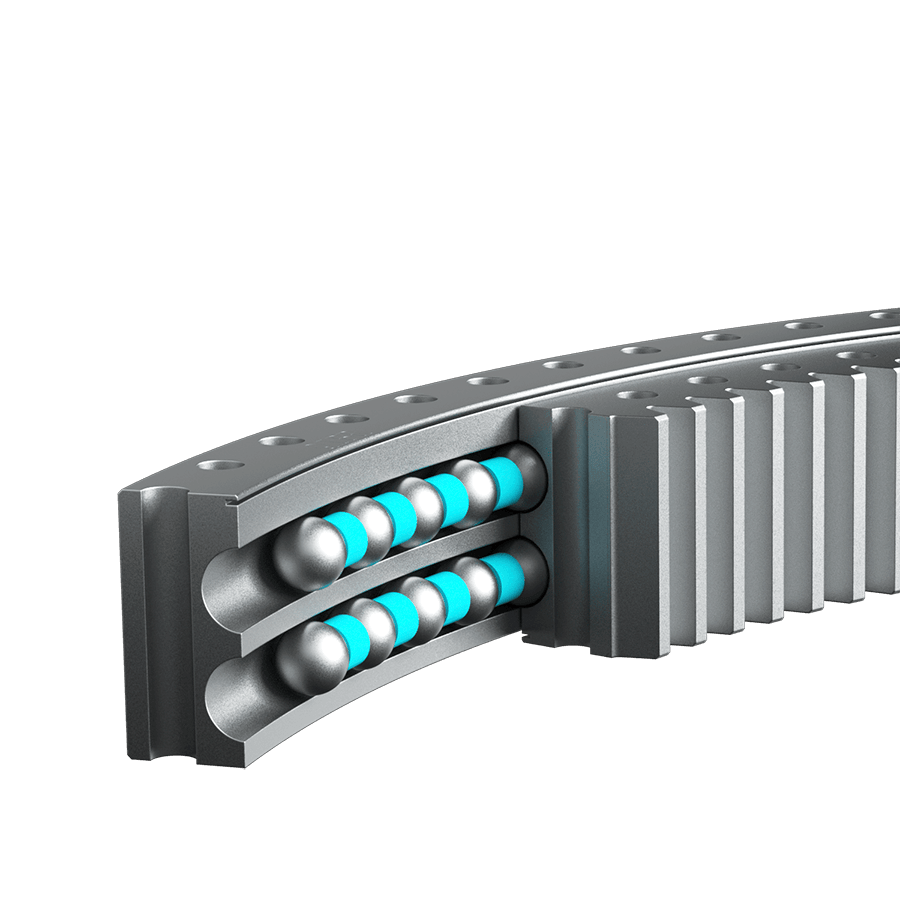

1. High load-carrying capacity : The Q16279001 slewing ring uses spheres as rolling elements, so that multiple rolling elements can contact the inner and outer rings at the same time, dispersing the load, and has a larger contact angle, which can withstand higher axial loads and improve the stability and load-bearing capacity of the bearing. It is suitable for the operation requirements of wind turbines under high wind speeds and dynamic loads.

2.Stability and durability : The Q16279001 slewing ring uses high-strength steel and advanced manufacturing technology, has low friction performance, can reduce energy loss, improve the overall efficiency of wind turbines, and improve their durability in harsh environments. Wind turbines are often exposed to harsh environments such as moisture and salt spray, and the stability and durability of the bearing are the key to their long-term stable operation.

3.Improve power generation efficiency : The inner and outer rings and rolling elements of the Q16279001 slewing ring are processed with high precision to ensure the smoothness and accuracy between the contact surfaces, which helps to reduce friction and uneven wear. Wind turbines can operate at higher efficiency, thereby improving power generation capacity.

Additional Notes:

QIBR Q16279001 slewing bearing has excellent load-bearing capacity and can withstand large radial and axial loads at the same time, ensuring the stability and safety of the equipment under extreme weather conditions. The Q16279001 slewing bearing adopts new high-strength materials and surface treatment technology to enhance the wear resistance and fatigue resistance of the bearing. Ensure the stability of the bearing in long-term operation and extend its service life. The American customer decided to purchase QIBR slewing bearing for wind turbines to meet its needs for stability and long life.