QIBR Sliding Bearings Delivered to Customer in Hamburg, Germany for Forging Machine Tools to Enhance Load Capacity and Stability

- Continent

- Europe

- Country

- Germany

- Date

- 2016-05-17

- Categories

-

Joint Bearing

- Applications

- Forging Machine Tools

Products Used

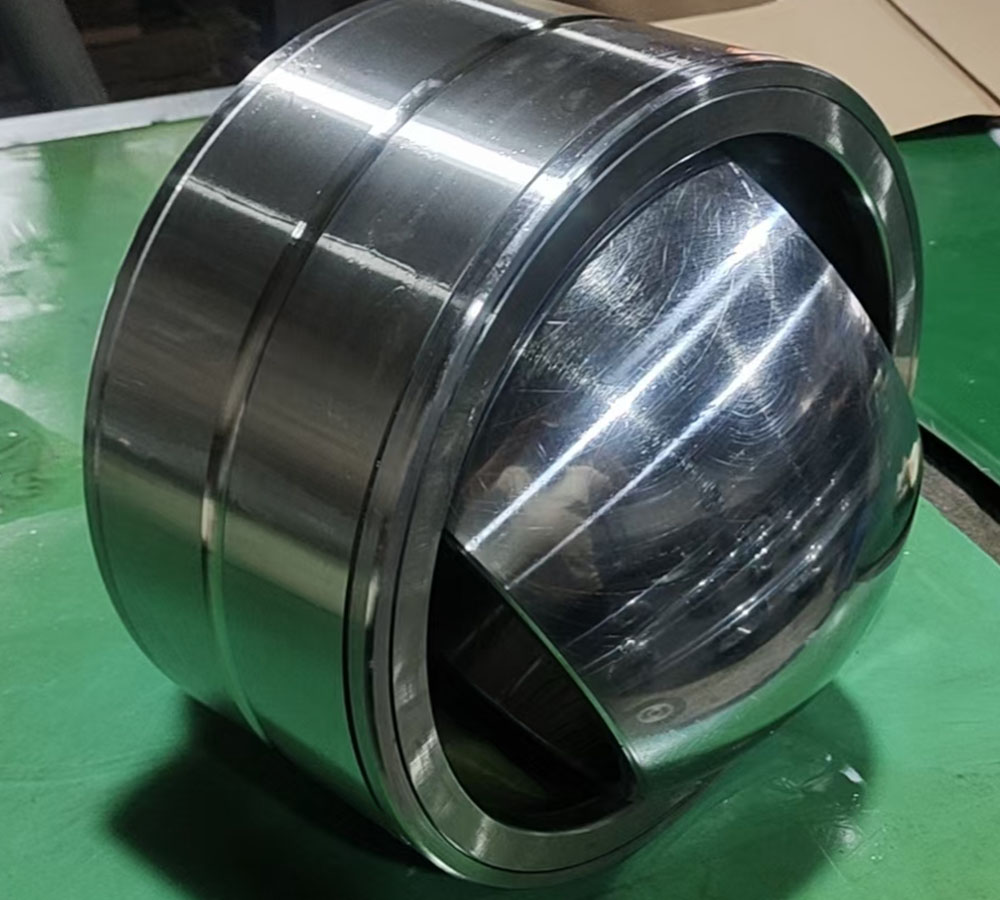

Sliding Bearings

1. Strong Impact Resistance: During the forging process, forging machine tools experience significant impact loads. The GE45HO2RS sliding bearing is made from high-strength, wear-resistant materials that maintain good performance under high loads and impact conditions. The toughness and plasticity of the materials effectively absorb impact energy, reducing the risk of damage.

2. Good Stability: The GE45HO2RS sliding bearing effectively absorbs and reduces mechanical vibrations. In high-frequency working environments, its excellent vibration-damping capability minimizes bearing damage caused by vibrations. Additionally, the GE45HO2RS sliding bearing maintains good performance over a wide temperature range, showing minimal performance degradation due to temperature changes.

3. High Load Capacity: The GE45HO2RS sliding bearing features a large contact area that allows loads to be evenly distributed across the entire contact surface. This reduces pressure per unit area and increases the bearing's load capacity, ensuring stability and safety for forging machine tools under high-load conditions.

Additional Notes:

The customer in Germany decided to purchase QIBR's GE45HO2RS sliding bearings to meet the demands of their forging machine tools for enhanced load capacity and stability. The GE45HO2RS sliding bearing offers high load capacity, excellent impact resistance, stable operating performance, low friction, and wear-resistant characteristics. It can withstand significant radial and axial loads, making it suitable for applications in forging machine tools under high-load conditions. During the forging process, significant impact loads are experienced. QIBR's GE45HO2RS sliding bearing uses high-performance materials and advanced manufacturing processes to effectively absorb and dissipate these impact forces, ensuring that the bearings maintain excellent performance even under high-speed operations and impact loading conditions.