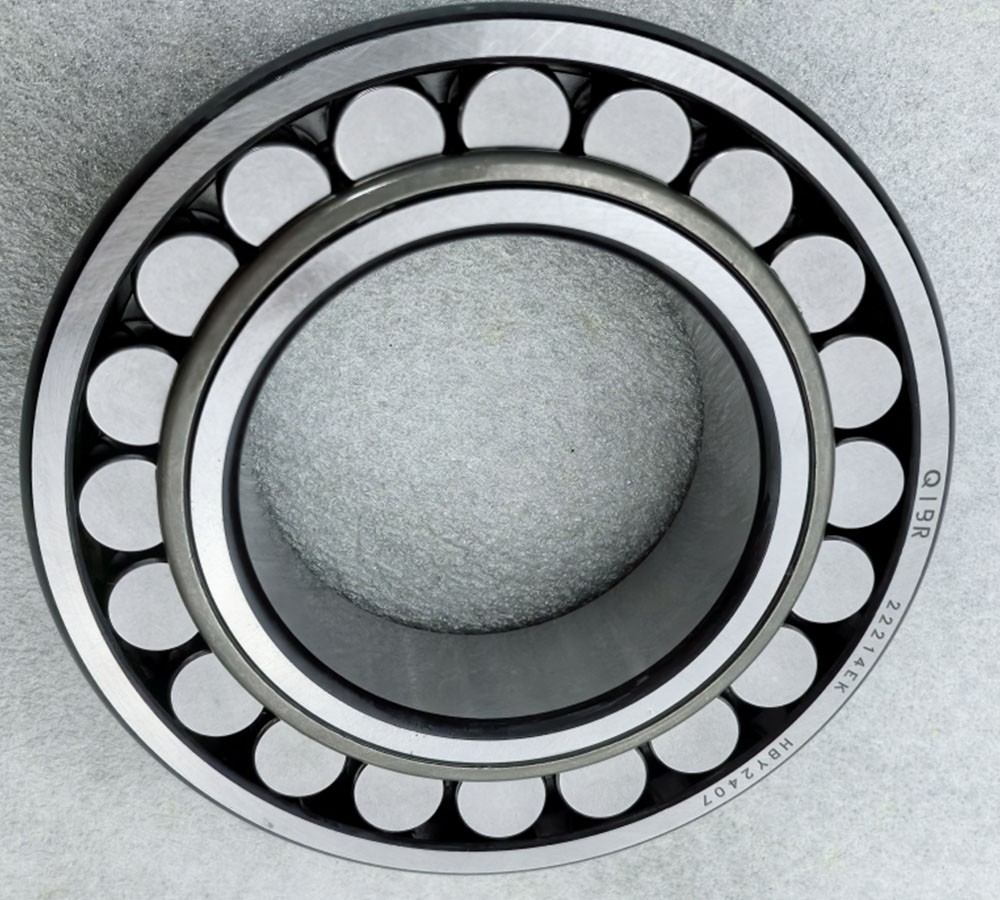

QIBR spherical roller bearings and deep groove ball bearings are delivered to customers in Frankfurt, Germany, and are used in industrial sand washing machines to improve efficiency and stability

- Continent

- Europe

- Country

- Germany

- Date

- 2016-04-20

- Categories

-

Deep Groove Ball Bearing

Spherical Roller Bearing

- Applications

- industrial sand washing machine

Products Used

Spherical roller bearing

1. Self-aligning ability: It has excellent self-aligning performance. When the shaft is bent or installed improperly, it can automatically adjust to compensate for these errors and ensure normal operation. This is very important in the working environment of sand washing machines that are often full of vibrations and impacts.

2. Strong load-carrying capacity: The 22214EK spherical roller bearing has two rows of rollers. The two raceways of the inner ring are inclined relative to the axis, which can effectively distribute the load, increase the bearing area, and improve the load-carrying capacity. It is suitable for the operation requirements of sand washing machines under heavy load and high impact conditions.

Deep groove ball bearing

1. Load-carrying capacity: The contact area between the ball and the inner and outer rings is large, effectively dispersing and supporting the load, and at the same time bearing a large radial and axial load, which can support complex load conditions in sand washing machines.

2. High-speed performance: Through advanced manufacturing processes, ensure the geometric shape and surface smoothness of the bearing, reduce friction and wear during operation, have a small friction coefficient, and increase the limit speed, so that it can achieve efficient operation in sand washing machines and reduce energy consumption.

Additional Notes:

German customers decided to purchase 22214EK spherical roller bearings and 6218 deep groove ball bearings from QIBR Company to improve the efficiency and stability of industrial sand washing machines. QIBR Company has advanced production facilities and a strict quality control system to ensure that each bearing can meet high-standard quality requirements. The 22214EK spherical roller bearing and 6218 deep groove ball bearing perform excellently in terms of wear resistance, load-carrying capacity and service life. The spherical roller has self-aligning ability, can effectively compensate for the deflection caused by improper installation of the shaft or equipment, and can bear large radial and axial loads. It is suitable for heavy-load work of industrial sand washing machines. The 6218 deep groove ball bearing has extremely low friction loss during operation and can effectively reduce energy consumption. The combined use of 22214EK spherical roller bearings and 6218 deep groove ball bearings can ensure the stable operation of sand washing machines under complex working conditions and give full play to their respective advantages.