QIBR Thrust and Deep Groove Ball Bearing Delivery to Birmingham, UK, for Aerospace Engine Mounts Stability and Safety

- Continent

- Europe

- Country

- United Kingdom

- Date

- 2016-07-08

- Categories

-

Deep Groove Ball Bearing

Thrust Ball Bearing

- Applications

- Vertical Centrifuges

Products Used

Deep Groove Ball Bearing

1. High Load Capacity: The 6203 N features deep grooves for simultaneous radial and limited axial load handling, suitable for engine mounts exposed to vibration and shock loads.

2. Operational Stability: Made from high-performance, wear-resistant materials, the 6203 N deep groove ball bearing offers corrosion resistance and stable performance at high speeds, reducing vibration and noise, thereby enhancing engine operation smoothness.

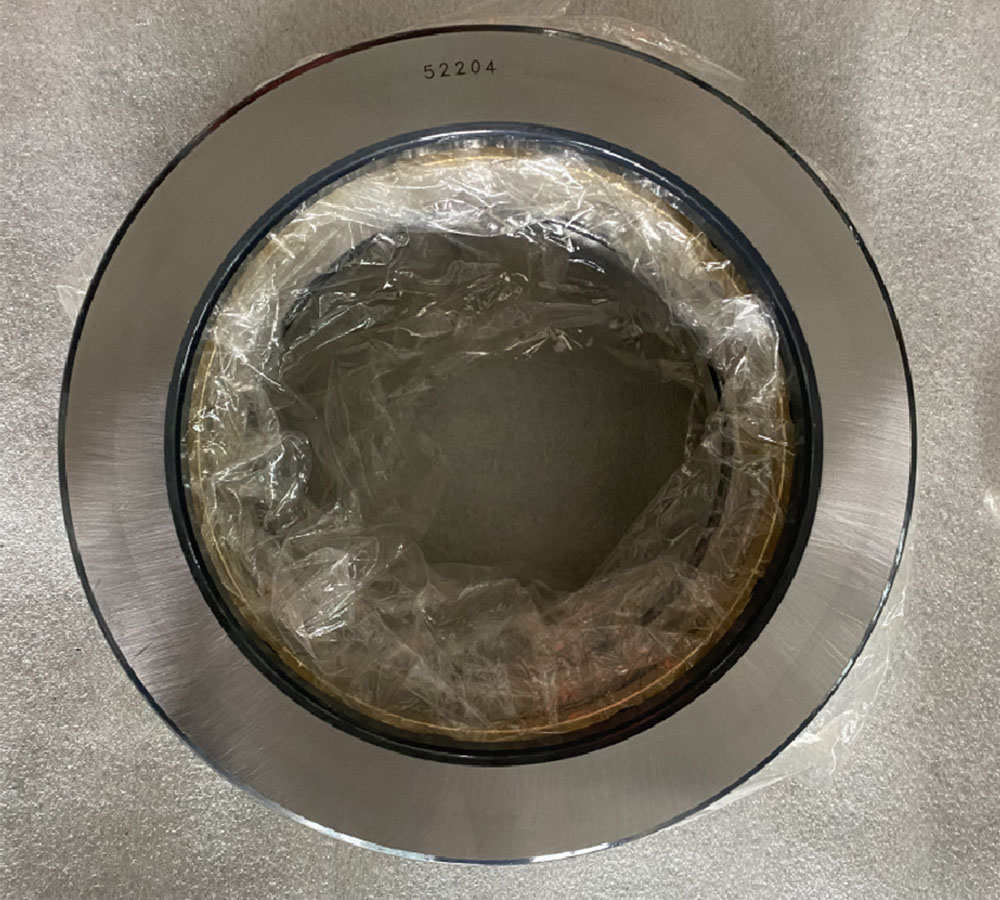

Thrust Ball Bearing

1. High Axial Load Capacity: Designed specifically for axial loads, the 52204 thrust ball bearing effectively distributes the force across the bearing to ensure stability under high-load conditions.

2. High Precision: Utilizing CNC machining and precision grinding, the 52204 maintains minimal dimensional tolerance, reducing shape and surface roughness errors, which enhances operational stability and accuracy.

3. Reduced Friction: Constructed with high-performance, hard-wearing materials and a smooth surface finish, the 52204 reduces friction, increasing wear resistance.

Additional Notes:

The UK client selected 52204 thrust and 6203 N deep groove ball bearings from QIBR to fulfill stringent stability and safety requirements for aerospace engine mounts. The 52204 bearing enhances mount stability, reducing vibrations and overall performance impact, while the 6203 N deep groove ball bearing, with its low friction feature, boosts engine system efficiency. QIBR bearings are constructed from high-temperature-resistant materials with specialized surface treatments for optimal corrosion and wear resistance. They maintain excellent performance in extreme operating environments, contributing to aerospace safety and reliability.