The slewing bearings of QIBR were delivered to customers in Brisbane, Australia, to improve the stability and precision of bridge inspection vehicles.

- Continent

- Oceania

- Country

- Australia

- Date

- 2016-10-02

- Categories

-

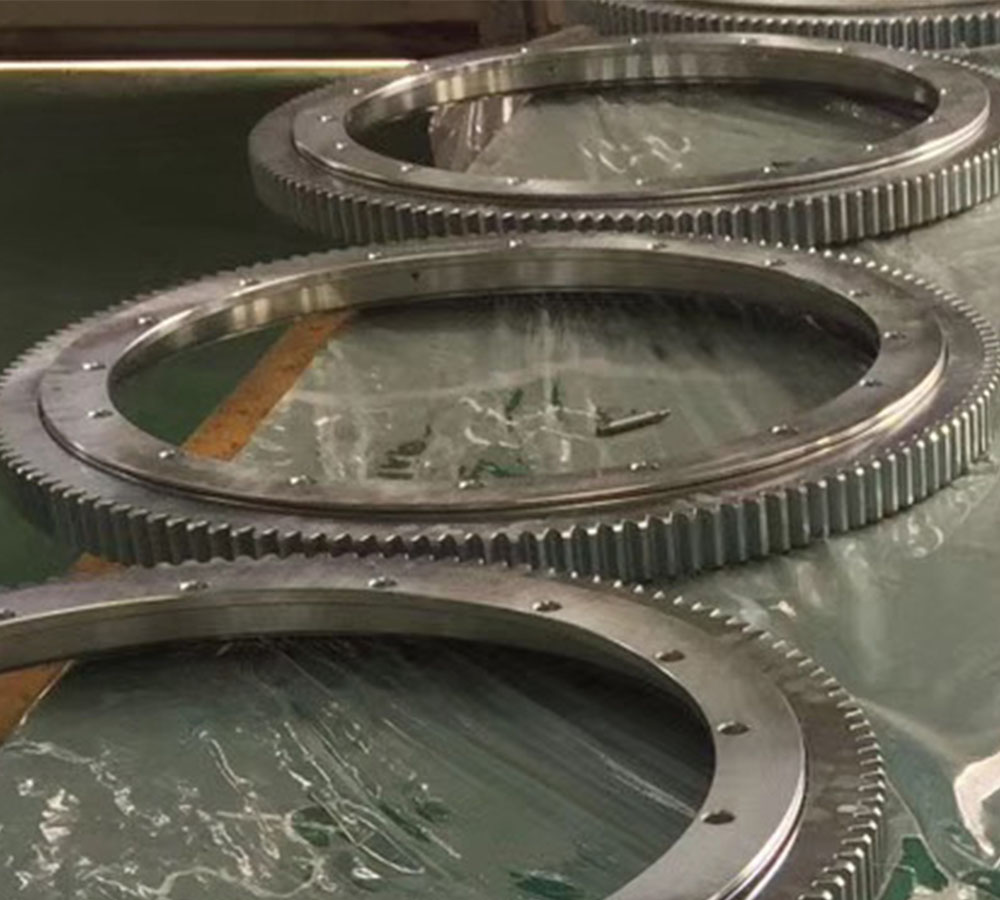

Slewing Bearing

- Applications

- Bridge Inspection Vehicles

Products Used

Slewing Bearing

1. High load capacity: The rolling elements inside the ER1.14.0544.200-1STPN slewing bearing form a relatively large contact area with the inner and outer rings. The load can be evenly distributed, reducing the pressure on individual contact points and increasing the load capacity. It can bear relatively large radial loads, axial loads and large overturning moments simultaneously.

2. Rotational Flexibility: The ER1.14.0544.200-1STPN slewing bearing can perform smooth rotational movements, which is suitable for the situation where bridge inspection vehicles frequently change directions during inspections. Good rotational performance can improve work efficiency and safety.

3. Compact Structure: The ER1.14.0544.200-1STPN slewing bearing is made of high-strength and lightweight materials, which have been specially treated to enhance strength and durability. While maintaining high load capacity, it can reduce the overall weight and achieve a more compact design, and can provide powerful support within a limited space. Bridge inspection vehicles can operate flexibly in narrow spaces.

Additional Notes:

The Australian customers decided to purchase the ER1.14.0544.200-1STPN slewing bearings produced by QIBR to meet the requirements of bridge inspection vehicles for improving stability and precision. The ER1.14.0544.200-1STPN slewing bearing adopts advanced design concepts and manufacturing processes, has extremely high precision, and ensures stable performance under the environment of high load and high-frequency operations, meeting the strict requirements of bridge inspection vehicles for precision and stability. QIBR provides customized solutions for the ER1.14.0544.200-1STPN slewing bearings according to customers' specific needs, precisely designs and manufactures bearing products that meet the requirements based on multiple parameters such as vehicle body structure, operation requirements and load conditions, so as to improve customers' user experience and product adaptability and meet the needs of different working environments.