Delivery of QIBR Sliding Bearings and Deep Groove Ball Bearings to Customer in Porto, Portugal for Enhancing Precision and Load Capacity in Double Piston Rod Cylinders

- Continent

- Europe

- Country

- Portugal

- Date

- 2016-06-25

- Categories

-

Deep Groove Ball Bearing

Joint Bearing

- Applications

- Double Piston Rod Cylinder

Products Used

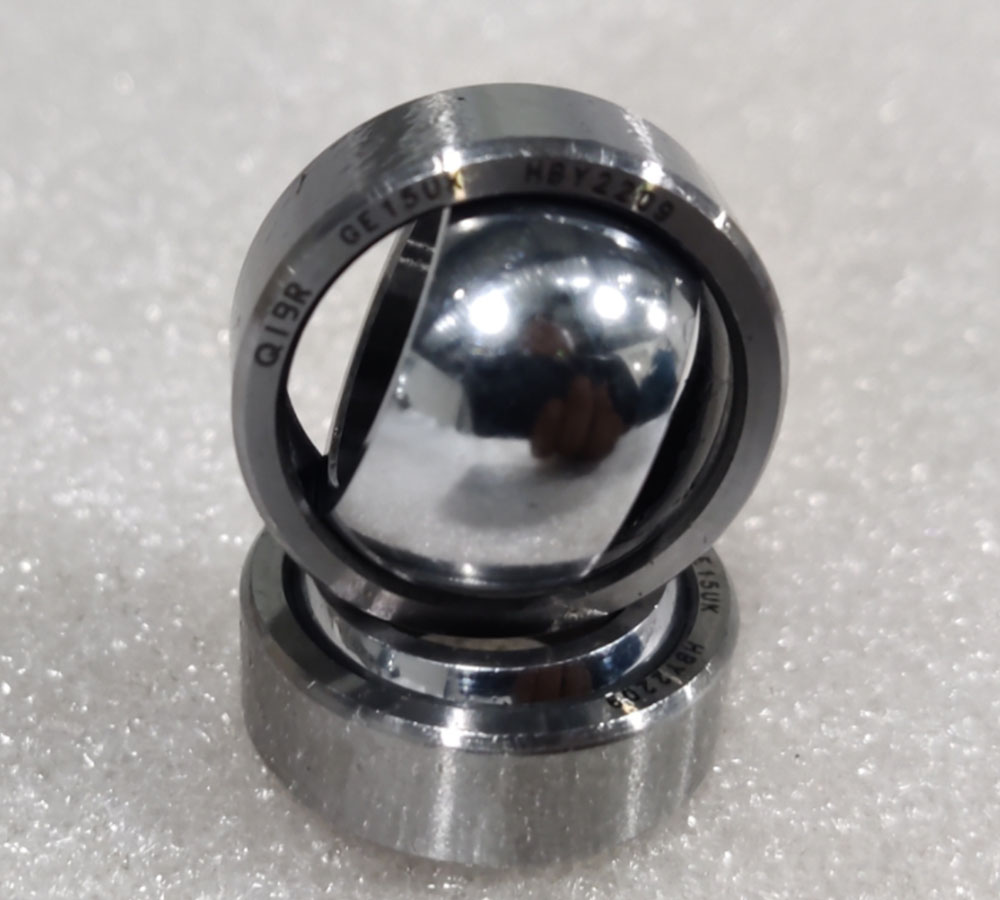

Sliding Bearings

1. Strong Load Capacity: The GE150UK sliding bearings have a large contact area, enhancing load capacity and allowing them to withstand impact and static loads during operation.

2. Low Friction and Wear: The inner and outer surfaces of the GE150UK sliding bearings are made from wear-resistant materials, with lubricants forming an oil film to reduce friction during sliding.

3. Smooth Operation: The GE150UK sliding bearings adapt to various operating conditions, generating minimal vibration and noise during operation, thus providing a smoother working environment.

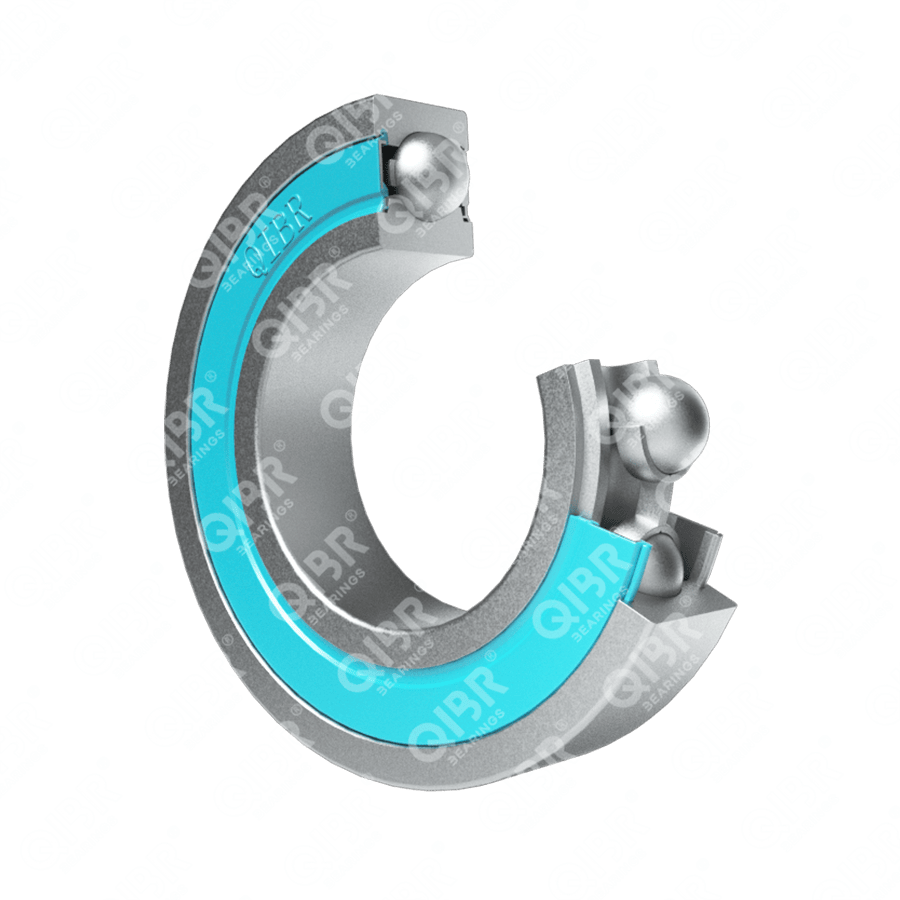

Deep Groove Ball Bearing

1. Strong Load Capacity: The deep grooves of the inner and outer rings of the 6004 2RS deep groove ball bearings increase the contact area between the rolling elements and the grooves, enabling them to bear both axial and radial loads effectively.

2. High Precision: The inner and outer rings, as well as the rolling elements of the 6004 2RS deep groove ball bearings, are manufactured through precise turning, grinding, and polishing processes, ensuring that the dimensions, shapes, and geometric accuracy meet high standards.

Additional Notes:

The Portuguese customer decided to procure QIBR's GE150UK sliding bearings and 6004 2RS deep groove ball bearings to meet the demands for improved precision and load capacity in double piston rod cylinders. Both the GE150UK sliding bearings and the 6004 2RS deep groove ball bearings have low friction coefficients, maintaining extremely low vibration and noise levels during high-speed operation of the double piston rod cylinders. By procuring QIBR's GE150UK sliding bearings and 6004 2RS deep groove ball bearings, the Portuguese customer can effectively enhance the performance of the double piston rod cylinders in terms of precision and load capacity. The combination of these two types of bearings can meet the industrial requirements for high loads, fast movement, and high precision, thereby improving the overall efficiency and reliability of the double piston rod cylinders.