QIBR Cylindrical Roller Bearings and Angular Contact Ball Bearings were delivered to customers in Jakarta, Indonesia, to enhance the load-carrying capacity and shock resistance of fuel injection pumps

- Continent

- Asia

- Country

- Indonesia

- Date

- 2016-07-27

- Applications

- Fuel Injection Pumps

Products Used

Angular contact ball bearing

1. High load - bearing capacity: The QJ218 angular contact ball bearings can bear both radial and axial loads simultaneously and can adapt to the complex working environment in fuel injection pumps.

2. Suitable for high-speed operation: The QJ218 angular contact ball bearings have low frictional resistance, which is suitable for fuel injection pumps to quickly and accurately inject fuel at high speeds, improving the injection efficiency.

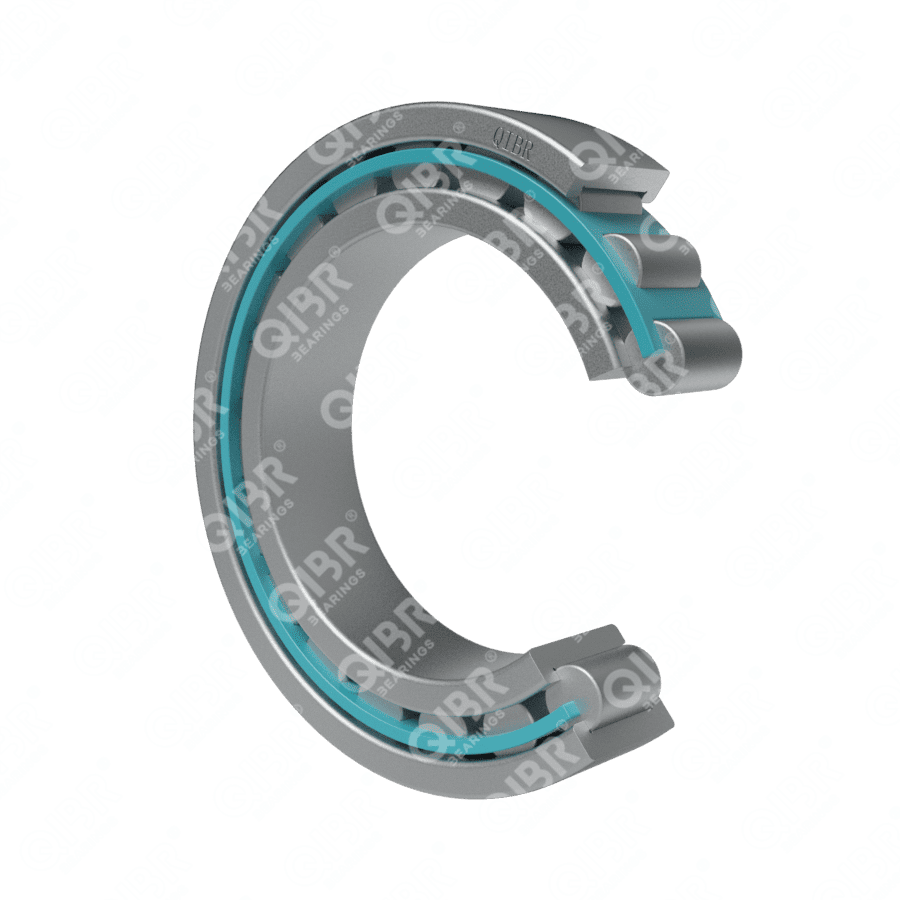

Cylindrical roller bearing

1. High load-carrying capacity :The rolling elements, inner ring and outer ring of the NJ 408 cylindrical roller bearings have a relatively large contact area, endowing them with high radial and axial load-carrying capacities. They can effectively support the high-pressure and high-load working conditions in fuel injection pumps.

2. Good Wear Resistance : The NJ 408 cylindrical roller bearings are manufactured from high-strength materials and undergo precision machining, thus possessing excellent wear resistance. The fuel injection pumps can maintain a good working condition.

Additional Notes:

The Indonesian customers decided to purchase the NJ 408 cylindrical roller bearings and QJ218 angular contact ball bearings from QIBR Company, aiming to improve the load-carrying capacity and shock resistance of the fuel injection pumps. The NJ 408 cylindrical roller bearings have a large contact area, can distribute loads, adapt to high-load environments, and ensure stable operation under high pressure. The QJ218 angular contact ball bearings are made of high-strength materials and advanced heat treatment processes, possess excellent shock resistance, can effectively absorb and distribute instantaneous impact loads, and extend the service life. The bearings of QIBR can maintain good performance under high-temperature conditions. The high-precision machining technology ensures extremely small tolerances inside the bearings, reduces frictional losses, and enhances the overall operational stability. They are suitable for the working environment of fuel injection pumps and reduce the risk of failures.