QIBR Cylindrical Roller Bearings and Sliding Bearings Delivered to UK Customer in Cardiff to Enhance Safety and Stability of Drilling Rig Slewing Platforms

- Continent

- North America

- Country

- The United States

- Date

- 2016-03-19

- Categories

-

Joint Bearing

Cylindrical Roller Bearing

- Applications

- Drilling Rig Slewing Platforms

Products Used

Joint Bearing

1. Suitable for High Loads: The GE240FO-2RS sliding bearing has a large contact area, allowing the load applied to the bearing to be distributed evenly, effectively dispersing the load and reducing local stress to improve its ability to withstand high loads.

2. High Stability: Made of wear-resistant materials, the GE240FO-2RS sliding bearing maintains good performance under high loads and harsh environments, enhancing stability.

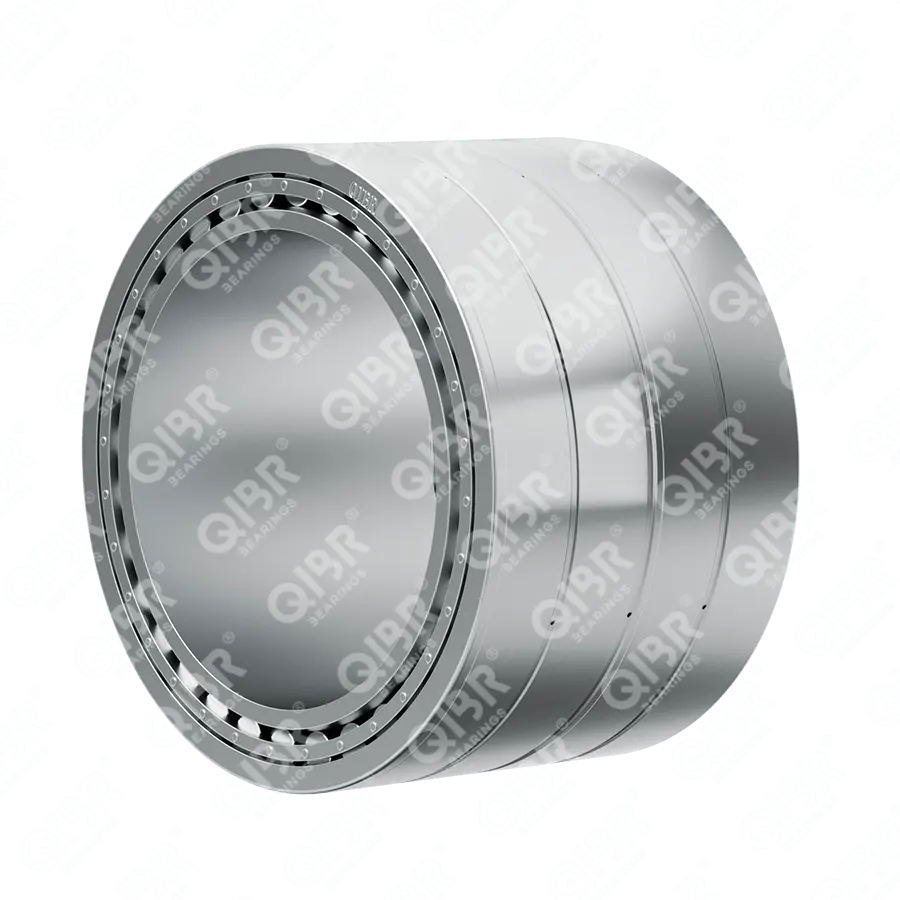

Cylindrical Roller Bearing

1. High Load Capacity: The FCDP112164600 cylindrical roller bearing can withstand large radial loads and impact loads. The small clearance between the rollers allows it to provide higher load support in a limited space, making it very suitable for use in drilling rig slewing platforms.

2. Wear Resistance: Made of high-strength materials and heat-treated, it has excellent strength and wear resistance, maintaining good performance under high loads and harsh working environments.

3. Low Friction and High Efficiency: The FCDP112164600 cylindrical roller bearing has a low coefficient of friction, helping to improve overall efficiency. In drilling operations, low friction results in less energy loss, improving fuel efficiency and operation speed.

Additional Notes:

The UK customer decided to purchase QIBR's FCDP112164600 cylindrical roller bearing and GE240FO-2RS sliding bearing to meet their strict requirements for safety and stability in drilling rig slewing platforms. The FCDP112164600 cylindrical roller bearing and GE240FO-2RS sliding bearing are made with premium materials and advanced manufacturing processes, significantly improving their wear resistance and fatigue life. This extends the product's service life, reduces maintenance frequency, and enhances the safety and reliability of the drilling rig slewing platforms. QIBR's bearings' high durability and low maintenance requirements allow the drilling rig slewing platforms to operate stably in harsh environments for an extended period, greatly reducing the risk of failure.