QIBR joint bearings were delivered to our customer in Philadelphia, USA, to improve the stability and longevity of ship internal combustion engines

- Continent

- North America

- Country

- The United States

- Date

- 2016-03-05

- Categories

-

Joint Bearing

- Applications

- Industrial robot base

Products Used

Joint bearing

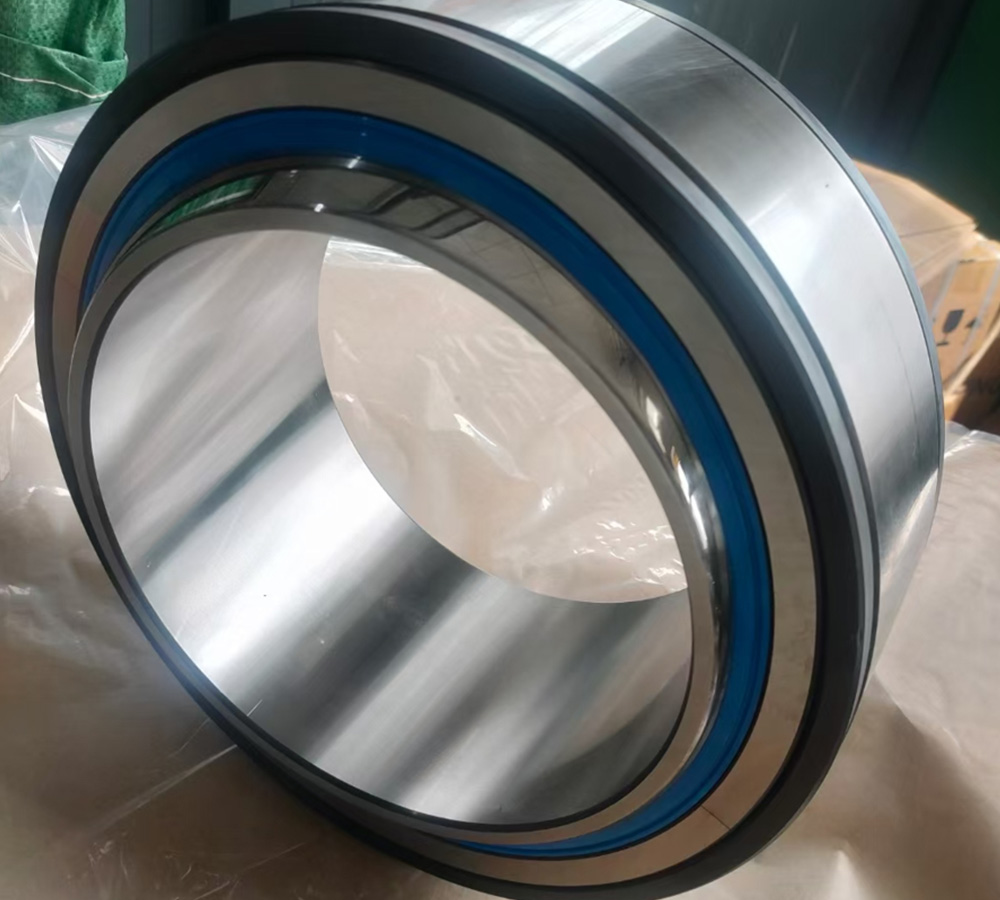

1. Strong load-bearing capacity: The contact area of the GE100FO-2RS joint bearing is relatively large. The large contact area can effectively reduce the pressure per unit area, help to disperse the load applied to the bearing, reduce wear, and can withstand large radial and axial loads. Suitable for ship internal combustion engines working under high load conditions.

2. High temperature resistance: The design of the GE100FO-2RS joint bearing is relatively simple, without a complex rolling element structure, and is not easy to deform at high temperatures. The GE100FO-2RS joint bearing is made of high temperature resistant materials and can maintain good performance in high temperature environments. The ship's internal combustion engine generates a lot of heat during operation, and the GE100FO-2RS joint bearing is still reliable under the high temperature working conditions of the internal combustion engine.

3. Low friction characteristics: The GE100FO-2RS joint bearing is specially surface treated by coating and polishing to reduce surface roughness. It can significantly reduce friction, improve operating efficiency, reduce friction coefficient, reduce energy loss, and improve the overall efficiency of the engine.

Additional Notes:

The American customer decided to purchase GE100FO-2RS joint bearing from QIBR to meet the safety, stability and long life requirements of ship internal combustion engines. The GE100FO-2RS joint bearing uses high-performance materials and advanced lubrication design, which can significantly reduce wear and extend the service life. The excellent durability and stability allow customers to reduce maintenance and replacement frequency and reduce long-term operating costs. In many years of practical applications, QIBR GE100FO-2RS joint bearings have demonstrated excellent performance stability, reducing downtime caused by failures and ensuring the safe navigation of ships.