QIBR's micro angular contact ball bearings and deep groove ball bearings are delivered to customers in Rio de Janeiro, Brazil, and are used in electric drilling rigs to improve stability and have a long service life

- Continent

- Sourth America

- Country

- Brazil

- Date

- 2016-04-22

- Applications

- electric drilling rig

Products Used

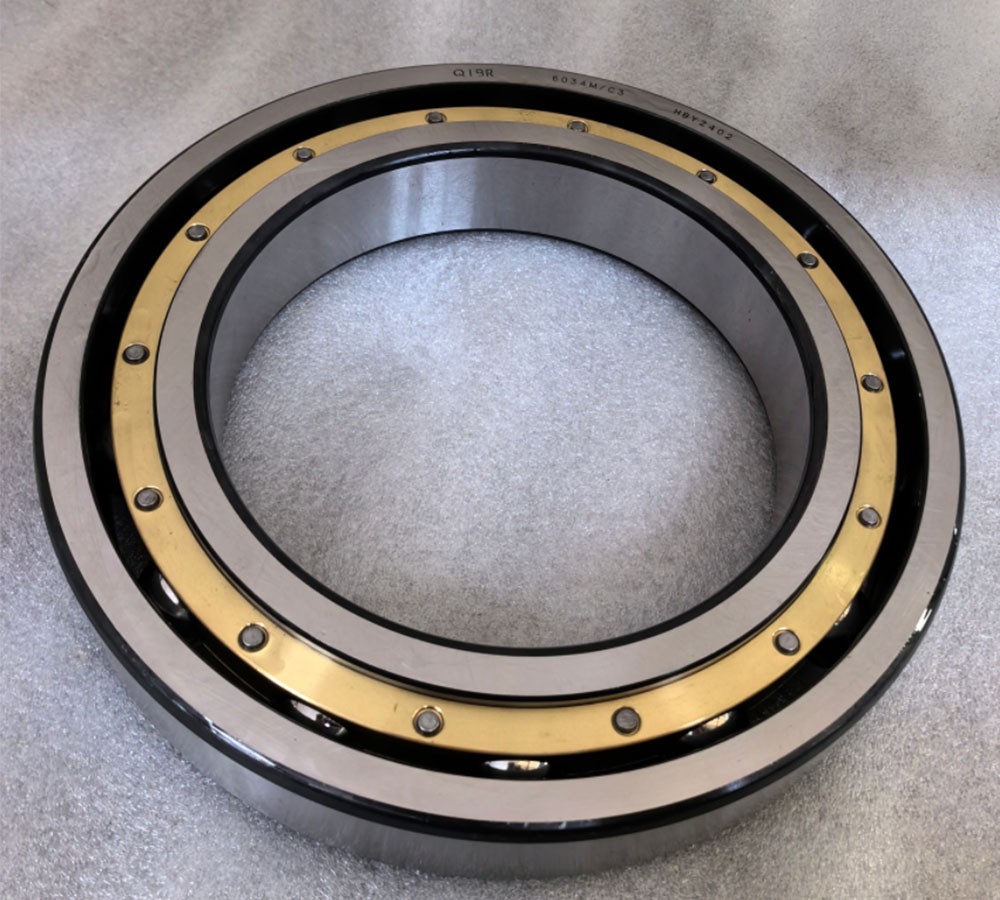

Deep groove ball bearings

1. Superior Load Capacity : The inner and outer raceways of the 6034M deep groove ball bearing are designed in a deep groove shape, and the contact area between the rolling elements and the raceway is relatively large. The larger contact area enables the load to be distributed more evenly, reducing local stress and improving load-carrying capacity. In electric drilling rigs, it can effectively support forces in different directions.

2. High-speed performance : High-quality materials and precise processing make the surfaces of the inner and outer rings of the 6034M deep groove ball bearing smooth, and the manufacturing process is very precise. The contact unevenness is small, reducing friction and wear.

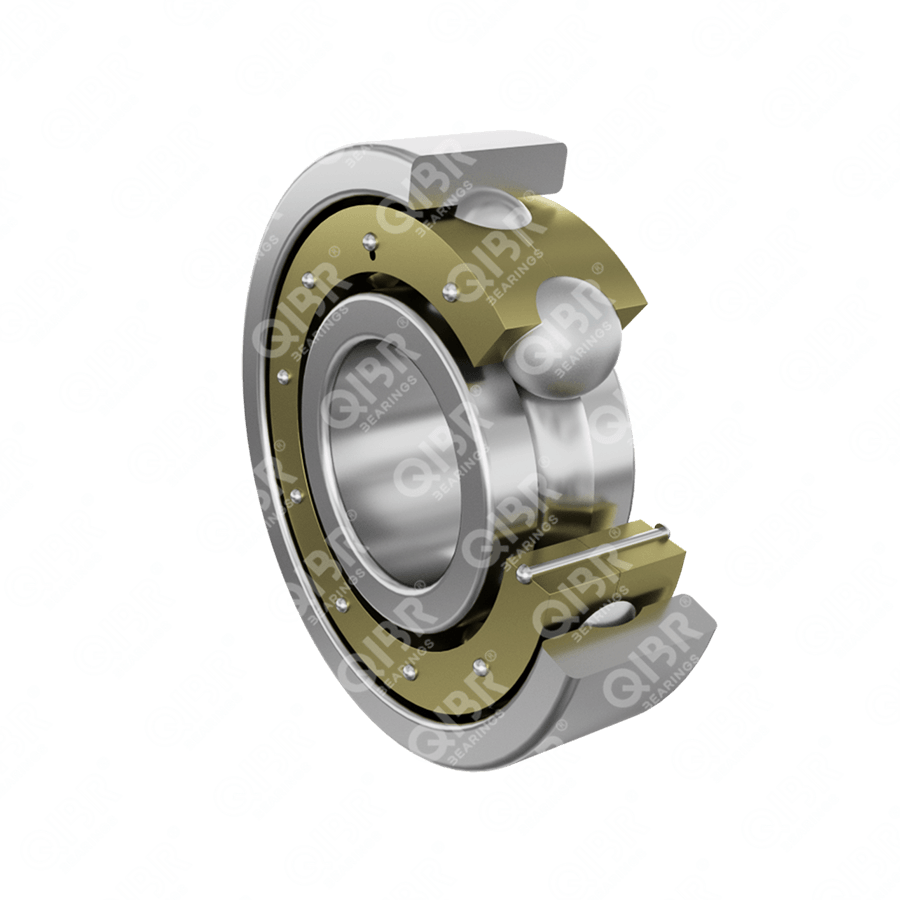

Angular contact ball bearing

1. Superior Load Capacity : It has a large contact angle, and the bearing has strong axial load-carrying capacity. The contact angle enables the load to be distributed in both radial and axial directions at the same time, improving the load-carrying capacity. Suitable for the complex loads generated by electric drilling rigs during operation. Ensure stability and reliability under high load conditions.

2. High precision : Strict tolerance control and high-precision processing technology in the manufacturing process ensure the dimensional accuracy of the bearing and can meet the requirements of high-precision applications. The high-precision design and manufacturing make the bearing maintain stable performance during operation and reduce vibration and noise.

Additional Notes:

Brazilian customers recently decided to purchase 7006C micro angular contact ball bearings and 6034M deep groove ball bearings from QIBR Company to meet the needs of electric drilling rigs in improving stability and extending service life. QIBR Company focuses on the research and development and production of high-precision 7006C micro angular contact ball bearings and 6034M deep groove ball bearings. Adopting high-performance materials and through strict production process control, ensure the stability of the bearings under high load and high speed conditions. The design of the 7006C micro angular contact ball bearing is optimized, with high radial and axial load-carrying capacity. When the electric drilling rig is working, it can maintain better stability and reduce vibration and noise. The 6034M deep groove ball bearing can provide smoother operation and ensure the continuous operation ability of the electric drilling rig.