QIBR Spherical Roller Bearings and Deep Groove Ball Bearings were delivered to customers in Brussels, Belgium, to enhance the stability and safety of mining screeners

- Continent

- Europe

- Country

- Belgium

- Date

- 2016-07-25

- Categories

-

Deep Groove Ball Bearing

Spherical Roller Bearing

- Applications

- Mining Screeners

Products Used

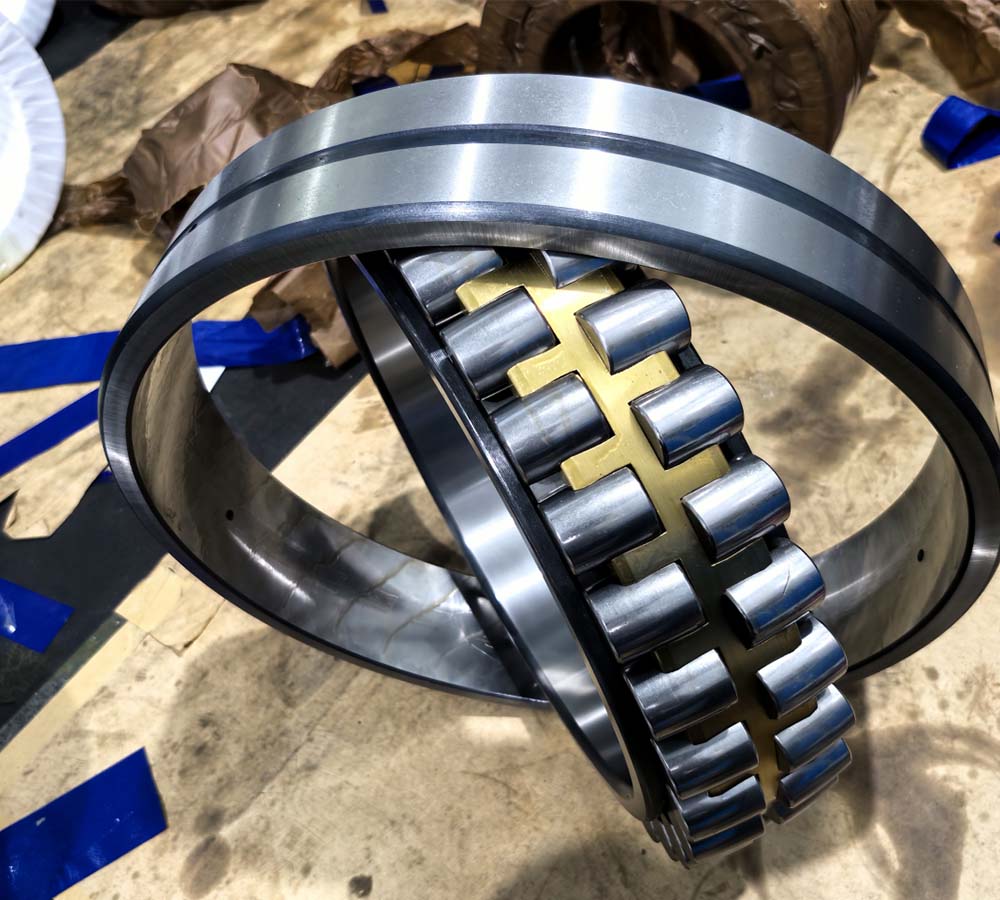

Spherical roller bearings

1. Self-Aligning Capability: The 21312 EK spherical roller bearings have good self-aligning ability, which can compensate for the coaxiality deviation caused by installation errors or shaft bending. Under vibration and impact loads, the mining screeners can effectively maintain stable operation.

2. High Load Capacity: The 21312 EK spherical roller bearings have a large contact area and can bear large radial and axial loads. They are suitable for the high-load requirements of mining screeners when handling large pieces of ore.

3. High Wear Resistance: Manufactured with high-strength materials and precision-machined, they possess good wear resistance. They can maintain a good working state during long-term operation and reduce the maintenance frequency.

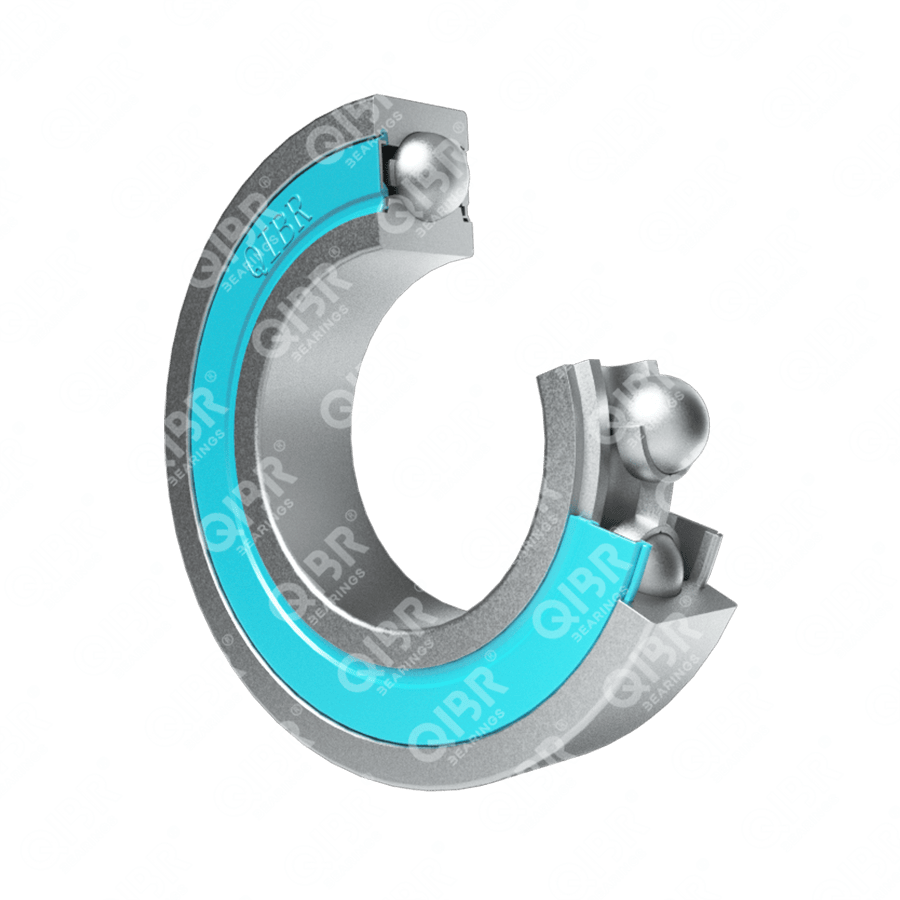

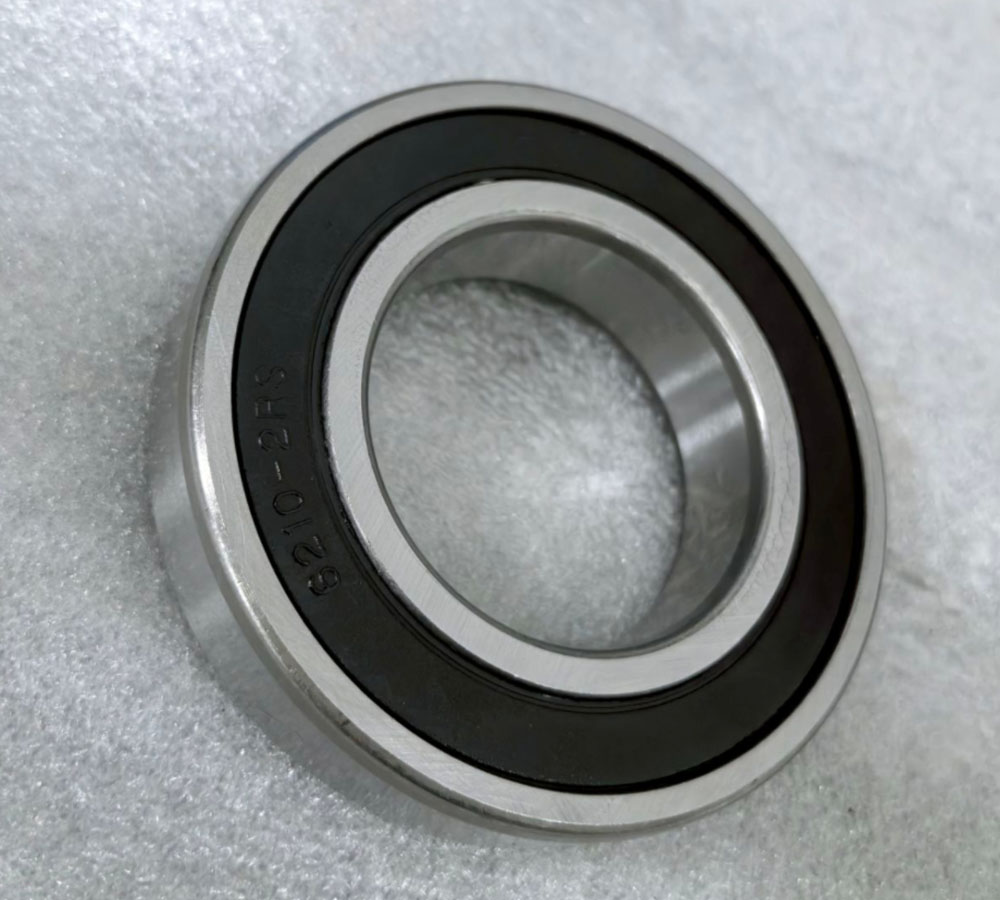

Deep Groove Ball Bearings

1. Multi-directional Load Capacity: The 6210 2RS deep groove ball bearings can bear radial loads and bidirectional axial loads simultaneously. They can adapt to the working environment with multi-directional forces acting on the mining screeners.

2. Low Friction: The 6210 2RS deep groove ball bearings have a simple structure, a low friction coefficient, are made of high-performance materials, possess excellent wear resistance and anti-fatigue properties, and can maintain low friction at high speeds, improving production efficiency.

Additional Notes:

The Belgian customers decided to purchase the 21312 EK spherical roller bearings and 6210 2RS deep groove ball bearings from QIBR Company to meet the requirements of mining screeners in terms of enhancing stability and safety. The 21312 EK spherical roller bearings can bear large radial and axial loads, effectively compensate for certain axial offsets, and improve the stability of the screeners. The 6210 2RS deep groove ball bearings are manufactured with advanced manufacturing techniques, possess extremely high precision and a smooth surface, have low friction losses during operation, and perform well in harsh environments such as mines. The bearings of QIBR can operate stably under both high and low temperature conditions, ensuring safety in extreme environments.